Leave Your Message

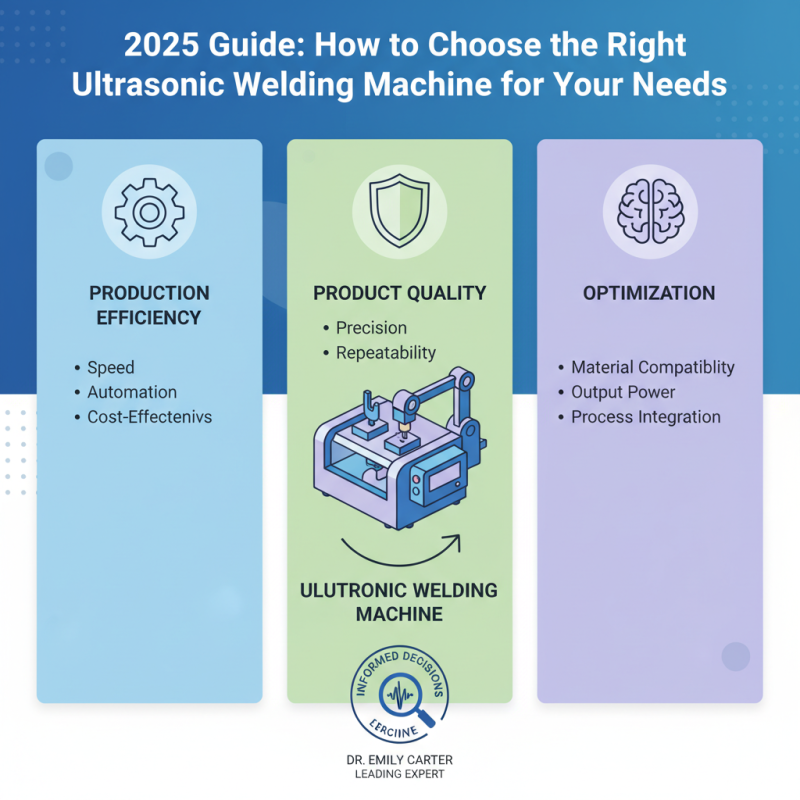

In today's rapidly evolving manufacturing landscape, the selection of an appropriate Ultrasonic Welding Machine is crucial for businesses aiming to enhance their production efficiency and product quality. According to Dr. Emily Carter, a leading expert in ultrasonic technology, "Choosing the right ultrasonic welding equipment is not just about functionality, but understanding how it can optimize your entire assembly process." Her insights underline the importance of making informed decisions when it comes to integrating this technology into your operations.

As industries expand and the demand for precision and speed increases, an Ultrasonic Welding Machine can offer significant advantages across various sectors, including automotive, electronics, and medical devices. Understanding your specific needs—be it the material compatibility, required output power, or the intricacies of the welding process—can ultimately define the success of your applications. This guide will navigate through the essential factors to consider, empowering you to choose an Ultrasonic Welding Machine that aligns with your production goals and enhances operational effectiveness.

Ultrasonic welding technology has revolutionized the manufacturing landscape, particularly in industries such as automotive, electronics, and medical device production. At its core, this process involves the use of high-frequency ultrasonic sound waves to create rapid vibrations between materials, resulting in the merging of thermoplastic components without the need for additional adhesives or fasteners. This approach not only enhances the strength of the bond but also significantly reduces cycle times, allowing for greater efficiency in production lines.

The applications of ultrasonic welding are vast and varied. In the automotive sector, it facilitates the assembly of lightweight components, contributing to fuel efficiency and dynamic performance. In electronics, it is employed for bonding delicate parts, such as circuit boards and components, while minimizing the risk of damage from heat or excessive pressure. The medical industry also benefits from ultrasonic welding for creating sterile packaging and ensuring reliable component assembly in devices. Understanding these applications is crucial when selecting an ultrasonic welding machine, as different materials and project requirements will dictate the specific technology and machine features needed for optimal results.

| Feature | Description | Recommended Application |

|---|---|---|

| Frequency | Typically ranges from 20 kHz to 70 kHz. | High-precision welding, micro-welding applications. |

| Power Consumption | Varies from 100W to 2000W. | Ideal for different scale productions. |

| Control System | Digital controls with user interface for settings. | User-friendly operation for various staff skill levels. |

| Welding Type | Spot welding, continuous welding, and stack welding. | Versatile applications depending on product design needs. |

| Weight | Ranges from 50 kg to 150 kg. | Influences installation and mobility requirements. |

| Material Compatibility | Suitable for thermoplastics, metal, and composite materials. | Enhanced flexibility in manufacturing processes. |

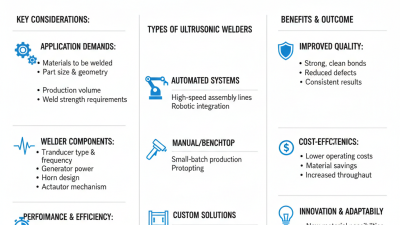

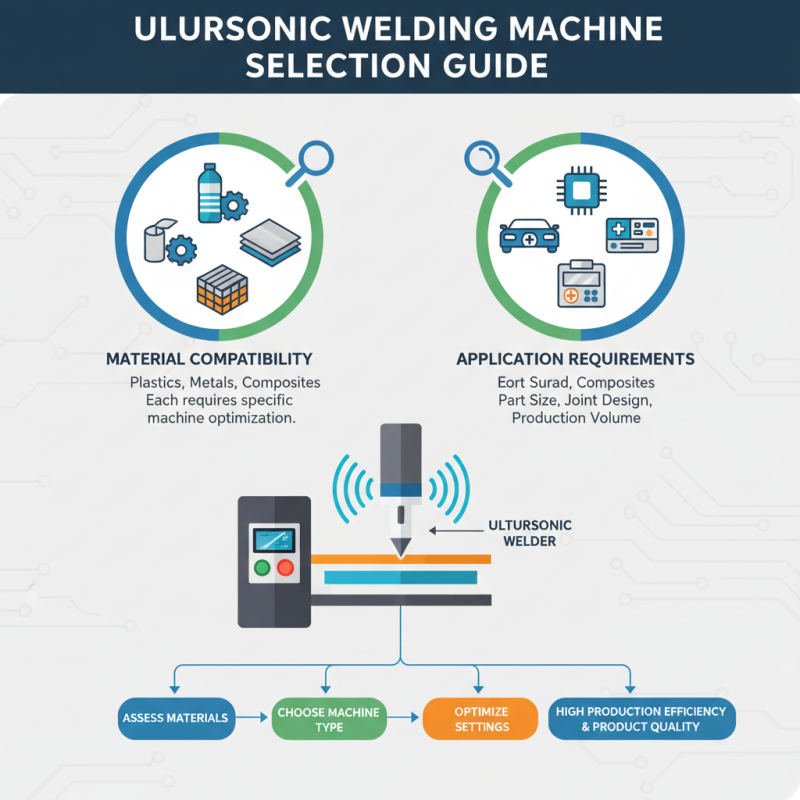

When it comes to selecting the right ultrasonic welding machine, there are several key factors to consider that can significantly impact your production efficiency and product quality. First and foremost, assess the materials you plan to weld. Different ultrasonic welding machines are optimized for various materials, such as plastics, metals, or composites. Understanding the specific requirements of your application is crucial for effective welding results.

Additionally, consider the power output and frequency of the machine. Higher power outputs typically allow for faster welding times, while the appropriate frequency ensures that the machine operates effectively with the materials used. Evaluate the production volume as well; if you're working on a high-output production line, a machine with a quicker cycle time and durability can be beneficial.

**Tips:** Always conduct a test weld before finalizing your choice. This helps identify any compatibility issues between the machine and the materials. Moreover, ensure that the machine has easy maintenance features and is supported by a reliable service network, as this can prevent long downtimes during production. Lastly, consider the size and footprint of the machine to ensure it fits into your operational space without compromising efficiency.

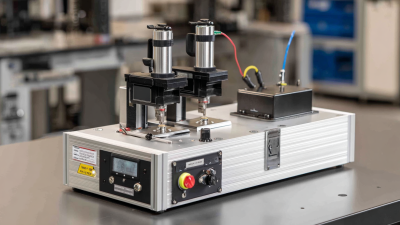

When selecting an ultrasonic welding machine, understanding the various types available is crucial for making an informed decision. The most common types include handheld units, bench-top machines, and automated systems. Handheld ultrasonic welders are ideal for small-scale operations or mobile applications. They offer portability and ease of use, allowing operators to perform welding tasks in diverse environments. Bench-top machines, on the other hand, provide more power and stability, making them suitable for higher production volumes and more complex welding tasks. These machines are often used in manufacturing settings, where precision and reliability are paramount.

Automated ultrasonic welding systems represent the next level of technology in this field. These machines are designed for high-volume production, often integrated into larger manufacturing lines. They come equipped with advanced features such as programmable parameters and digital interfaces, enhancing usability and precision. Additionally, automated systems often include various feeding mechanisms and tooling options, catering to specific application needs. By comparing the features and benefits of these different types of machines, potential buyers can better align their selection with their production requirements, ultimately leading to increased efficiency and reduced operational costs.

When selecting the right ultrasonic welding machine, understanding your production needs is crucial. Factors such as size, material, and frequency play significant roles in determining the suitability of a machine for specific applications. According to a recent industry report from Research and Markets, the global ultrasonic welding equipment market is projected to reach $1.02 billion by 2025, emphasizing the growing demand for tailored solutions across various sectors.

Size is a fundamental consideration. The dimensions of the machine must align not only with the workspace but also with the intended production scale. For instance, a larger machine may be necessary for high-volume production lines, capable of processing substantial batches without sacrificing quality.

Additionally, material compatibility is essential; different materials, such as plastics, metals, or composites, require specific welding frequencies and ultrasonic parameters. Studies indicate that the right frequency can enhance the bond strength and reduce cycle time, making material evaluation an integral part of the selection process.

Frequency, typically ranging from 20 kHz to 40 kHz, directly impacts the efficiency and effectiveness of the welding process. Industries like automotive and electronics often utilize lower frequencies for thicker materials, while higher frequencies are suitable for delicate components.

By carefully assessing your production requirements in relation to these parameters, you can make an informed decision that optimizes both performance and cost-efficiency.

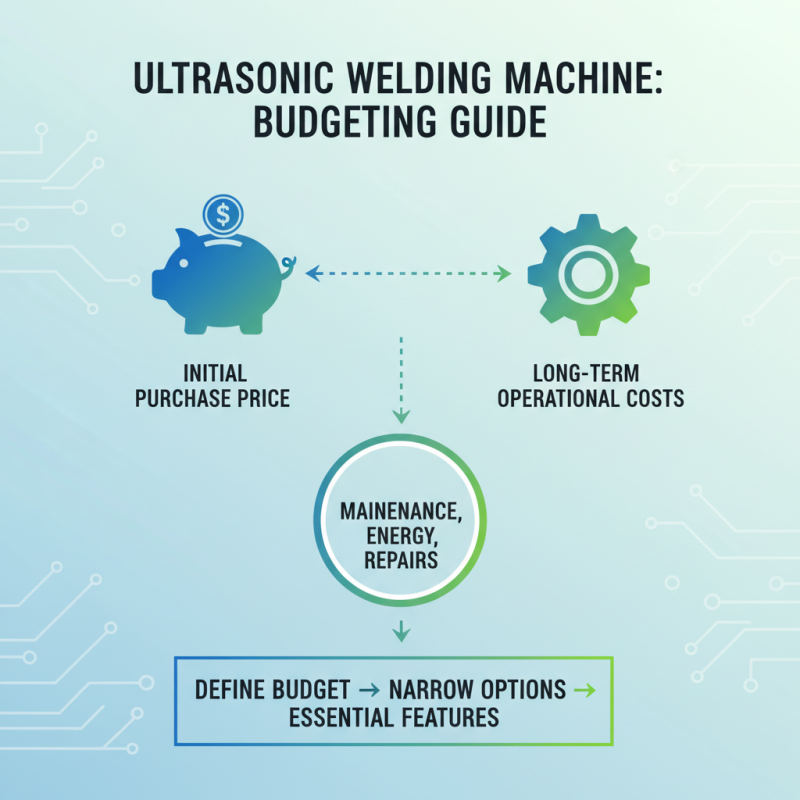

When considering the purchase of an ultrasonic welding machine, budgeting is a crucial factor that can significantly influence your decision-making process. It’s essential to define a clear budget by evaluating both the initial purchase price and the long-term operational costs. This includes maintenance, energy consumption, and potential repairs. Setting a budget will not only help you narrow down your options but also enable you to assess which features are essential for your specific needs without overspending.

To find cost-effective solutions, consider the various types of ultrasonic welding machines available in the market and their unique features. Look for models that offer the best balance between cost and functionality, and investigate if there are financing options or leasing agreements that might make purchasing more feasible. Additionally, researching second-hand machines can be an effective way to save money while still acquiring a quality product, as long as the equipment has been well-maintained. By conducting thorough research and being mindful of your budget, you can identify an ultrasonic welding machine that meets your operational requirements without compromising on quality.