Leave Your Message

The manufacturing landscape is witnessing a transformative shift with the advent of advanced Ultrasonic Welder Machines. As industries strive for higher efficiency and precision, these cutting-edge devices are emerging as essential tools in modern production lines. According to a recent report by MarketsandMarkets, the ultrasonic welding market is projected to reach $2.6 billion by 2025, growing at a CAGR of 6.2% during the forecast period. This growth is largely attributed to the increasing demand for lightweight and high-strength materials across various sectors, including automotive, electronics, and medical device manufacturing.

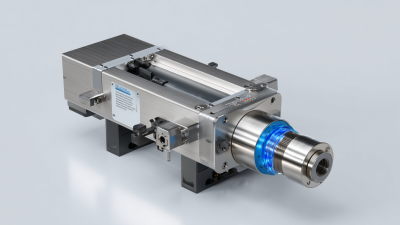

The innovations driving this market are not only enhancing welding capabilities but also significantly improving operational efficiencies. Ultrasonic welding technology utilizes high-frequency vibrations to create strong, reliable joints between thermoplastics and metals, often eliminating the need for adhesives or mechanical fasteners. Recent advancements in digital controls and automated systems have further minimized human errors and downtime in production processes. As we approach 2025, the focus will shift towards the top 10 Ultrasonic Welder Machines that epitomize these innovations, setting new benchmarks for quality and efficiency in manufacturing. Understanding these trends and the leading technologies will be crucial for businesses looking to remain competitive in an ever-evolving marketplace.

The ultrasonic welding technology is experiencing remarkable advancements as we approach 2025, significantly impacting various manufacturing sectors, particularly the medical industry. The global market for ultrasonic welding machines is poised to reach an estimated value of $142.85 million in 2025, with projections indicating growth to $217.57 million by 2033. This growth corresponds to a compound annual growth rate (CAGR) of 5.4%, illustrating the technology's increasing adoption and enhancement in efficiency.

Recent innovations, such as servo ultrasonic welding technology, are leading firms to enhance their productivity and reliability. The market for ultrasonic plastic welding machines alone was valued at $320 million in 2022 and is expected to grow to $550 million by 2030, with a CAGR of 7.2% from 2024 to 2030. As companies invest in state-of-the-art welding solutions, the competitive landscape is shifting, underscoring the need for manufacturers to stay at the forefront of technology in order to thrive in this evolving market.

When exploring the advancements in ultrasonic welder machines for 2025, it is crucial to identify key features that can significantly enhance manufacturing efficiency. An industry report by MarketsandMarkets predicts that the ultrasonic welding market will grow from $1.2 billion in 2020 to $1.8 billion by 2025, underscoring the rising demand for these innovative solutions. One essential feature to consider is the power output of the machine, which affects the speed and quality of the welding process. Machines with a higher wattage can handle thicker materials and achieve stronger welds, making them ideal for diverse applications in industries like automotive and electronics.

Another important aspect is the precision control systems incorporated in modern ultrasonic welders. These systems not only improve weld consistency but also minimize waste and enhance overall material utilization. According to a report by BCC Research, manufacturers implementing precision control in their processes have reported efficiency increases of up to 30%. Additionally, features such as digital displays, programmable settings, and real-time monitoring capabilities allow operators to fine-tune the welding parameters, ensuring optimal performance for various materials and thicknesses. By prioritizing these key features, manufacturers can maximize productivity and maintain a competitive edge in the evolving market landscape.

The comparative analysis of ultrasonics and laser-assisted technologies highlights significant advancements in manufacturing efficiency, especially in industries like leather production. As sustainable practices gain momentum, ultrasonic welders stand out due to their ability to minimize environmental impact while enhancing precision and speed in processing materials. The integration of these advanced techniques not only streamlines operations but also supports the growing demand for eco-friendly manufacturing solutions.

In examining the top ultrasonic welder machines of 2025, features such as energy efficiency, higher throughput, and improved material compatibility emerge as key drivers of innovation. This ongoing evolution in welding technology is underscored by market forecasts indicating a substantial growth trajectory for the ultrasonic welding systems market. The projected increase in market size to USD 1,156 million by 2034 reflects the urgent need for manufacturers to adopt advanced welding solutions that not only meet production demands but also align with sustainable industry practices. The emphasis on efficiency through comparative analyses reveals how adopting state-of-the-art welders can significantly impact manufacturing productivity and environmental responsibility.

| Model | Welding Frequency (kHz) | Power Output (W) | Weight (kg) | Materials Compatibility | Efficiency Rating |

|---|---|---|---|---|---|

| Model A | 20 | 1500 | 45 | Plastics, Metals | 95% |

| Model B | 28 | 1200 | 50 | Plastics | 92% |

| Model C | 35 | 1800 | 60 | Metals | 98% |

| Model D | 40 | 2000 | 55 | Composite Materials | 97% |

| Model E | 25 | 1600 | 48 | Plastics, Ceramics | 94% |

The Global Ultrasonic Welding Systems Market is projected to reach USD 1,156 million by 2034, growing at a CAGR of 5.1%, according to a recent report by Custom Market Insights. This growth is fueled by the rising demand for efficient manufacturing processes, particularly in industries such as automotive, aerospace, and electronics. Innovations in ultrasonic welding technology are significantly impacting production costs and speed, enabling manufacturers to achieve tighter tolerances and faster cycle times. With over 30 major manufacturers adopting advanced ultrasonic bonding technologies, the push for increased automation and process efficiency is reshaping the competitive landscape.

One of the notable advancements is the integration of digital twin technology, which allows manufacturers to simulate processes and optimize workflows before production begins. These innovations are essential as companies like Boeing and Airbus explore lightweight composite materials to meet the demands of next-generation aircraft, emphasizing the need for reliable and efficient joining methods. The emergence of robotics, such as automated weld inspection systems, further enhances operational capabilities, allowing for rapid assessments and improved safety protocols in critical applications, such as nuclear reactor maintenance. As industries continue to seek ways to enhance efficiency and reduce costs, the role of ultrasonic welding technology is set to expand, making it a focal point of modern manufacturing strategies.

This chart illustrates the estimated reduction in production costs and increase in speed achieved through different ultrasonic welder innovations. The data reflects the improvements across various manufacturing processes.

As we approach 2025, the ultrasonic welding market is poised for significant transformation, particularly in the medical and semiconductor sectors. The global market size for ultrasonic welders in healthcare is projected to reach $142.85 million by 2025, with an impressive growth forecast to $217.57 million by 2033. This represents a compound annual growth rate (CAGR) of 5.4%, indicating a sustained interest in innovative welding solutions that enhance manufacturing efficiency.

Moreover, the semiconductor industry's progress is driving demand for advanced ultrasonic technology tailored for specialized applications. Recent investigations reveal that companies are developing comprehensive ultrasonic solutions capable of meeting the diverse parameter requirements and technical complexities across different fields, including emerging sectors like renewable energy. The market for ultrasonic plastic welding machines is also expanding, expected to grow from $320 million in 2022 to $550 million by 2030, demonstrating a CAGR of 7.2% from 2024 to 2030. This momentum highlights the critical role that ultrasonic welding will play in various future manufacturing processes.