Leave Your Message

The demand for Ultrasonic Welding Machines is rapidly increasing across various industries. Studies show that the market for ultrasonic welding is expected to grow at a CAGR of 6.2% from 2023 to 2028. This growth is driven by the need for efficient and precise joining techniques.

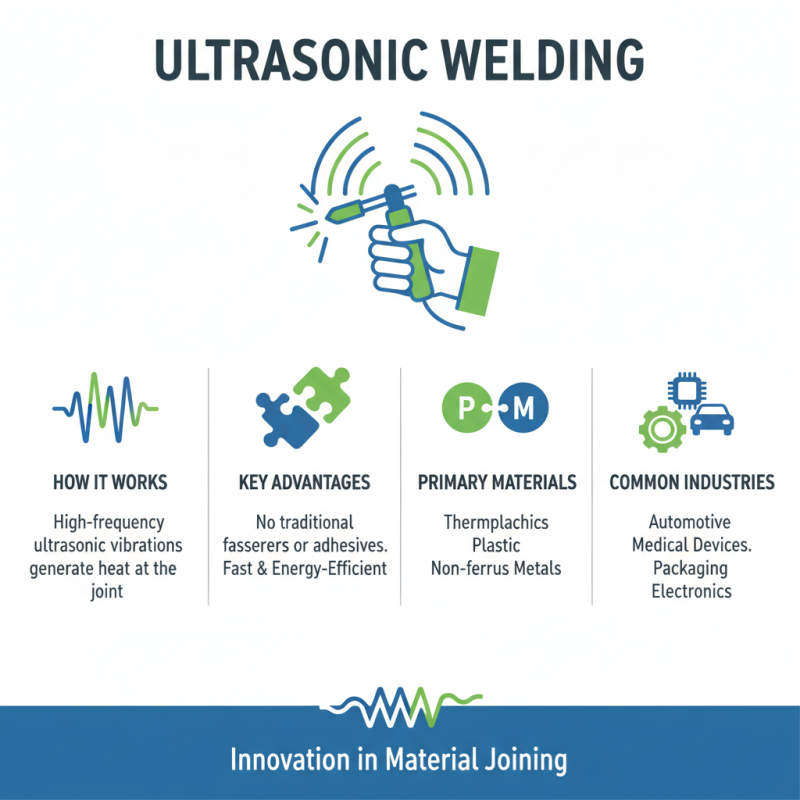

Ultrasonic welding offers unique advantages. It provides clean joints without contaminants, which is essential in fields like medical device manufacturing. The technology uses high-frequency vibrations, creating localized melting of thermoplastics. This method reduces cycle times and energy consumption. In fact, manufacturers can save up to 30% on energy costs by switching to ultrasonic welding processes.

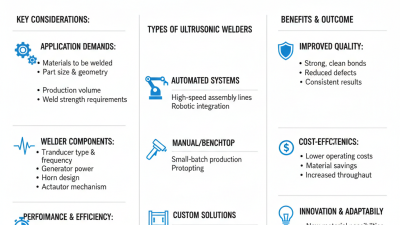

However, challenges remain. Not all materials are suitable for ultrasonic welding. Some require additional considerations, like material thickness and type. As industries evolve, the need for optimization in ultrasonic welding operations continues. These factors highlight the importance of understanding the features and benefits of the 2026 Ultrasonic Welding Machines for various applications.

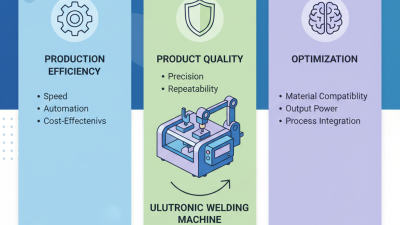

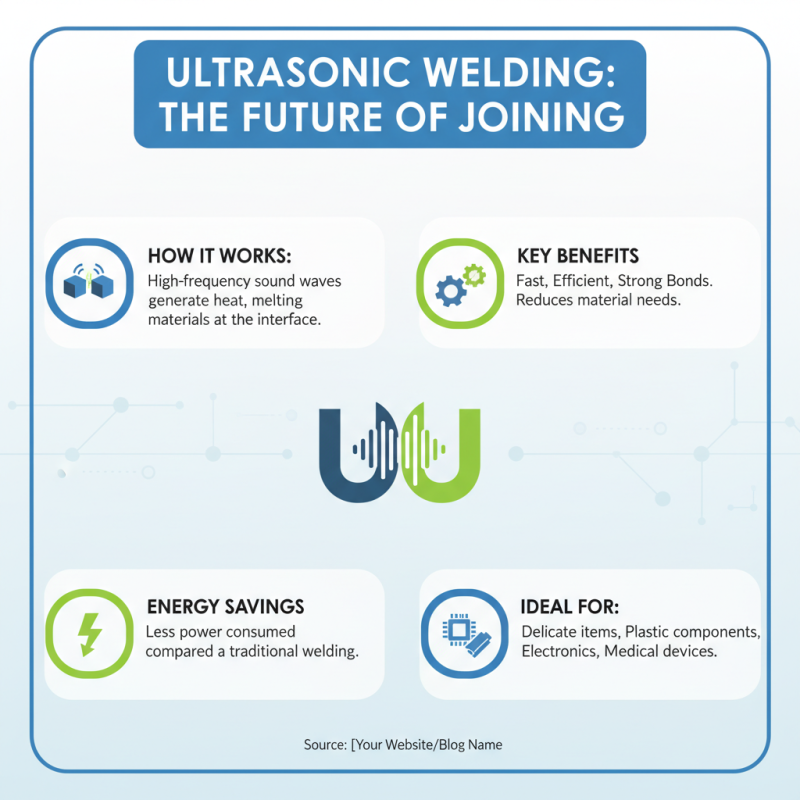

Ultrasonic welding has advanced significantly by 2026, offering vital features to various industries. One notable aspect is the enhanced energy efficiency. Recent industry reports indicate that modern ultrasonic machines can achieve up to 80% energy savings compared to traditional methods. This efficiency not only reduces operational costs but also benefits the environment.

Another key feature is the improved precision in welding. The latest machines are designed to deliver consistent weld quality with minimal defects. For instance, studies show that the ultrasonically welded joints can reach adhesion strengths exceeding 90% of the parent materials. This is crucial in sectors like automotive and electronics, where the integrity of components is vital. However, users must be cautious. Despite advancements, some machines require extensive calibration, which can lead to inconsistencies if not properly managed.

Moreover, versatility remains a strong selling point. Today’s machines can work with various materials, from plastics to metals. Reports suggest that over 60% of manufacturers are now adopting this technology for diverse applications. However, understanding the specific requirements for each material can be challenging. Companies should invest time in training staff to harness the full potential of these machines. This investment is essential for maximizing productivity and ensuring quality outcomes.

Ultrasonic welding technology offers several advantages in manufacturing. It provides strong, reliable bonds without needing additional materials like adhesives. This process reduces overall production time. The welding only takes a few seconds, allowing for quicker project completion. Moreover, it can be applied to various materials, including plastics and metals. However, this versatility demands careful attention to material compatibility.

One notable benefit is the reduced environmental impact. Since ultrasonic welding does not require solvents, it generates less waste and harmful emissions. Another aspect is the precision it offers. The localized heat minimizes damage to surrounding areas. Despite these positives, operators must understand the machine's limitations. For example, excessive energy can lead to material degradation. Proper training is essential to maximize the technology's benefits while avoiding costly mistakes.

Ultrasonic welding has become a vital technology in various industries. It joins materials using high-frequency ultrasonic vibrations. This process generates heat, allowing materials to bond without traditional methods. It's particularly effective for thermoplastics and metals.

In the automotive sector, ultrasonic welding is essential for creating intricate components. It enables secure assembly of parts like sensors and switches. The medical industry also benefits significantly. Equipment and devices often require sterilization, making ultrasonic welding a great fit. It's clean and quick, minimizing contamination risks.

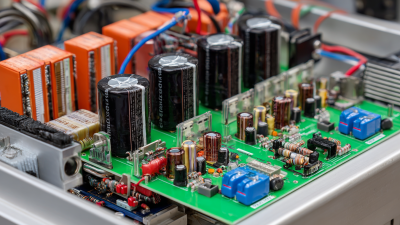

Electronics manufacturing relies heavily on this technology. Ultrasonic welding ensures reliable connections in small components, like circuit boards. It can join dissimilar materials too, broadening its applications. An area for improvement is the need for consistent quality in challenging materials. Sometimes, achieving the perfect bond can be elusive, requiring further refinement.

Ultrasonic welding stands out among various joining methods. It uses high-frequency sound waves to create strong bonds. This process generates heat, melting materials at the interface. It's quick, efficient, and reduces the need for additional materials. Unlike traditional welding, ultrasonic welding requires less energy. It can be used on delicate items like plastic components.

When compared to adhesive bonding, ultrasonic welding offers faster processing times. Adhesives often need curing, which can slow production. Welded joints also tend to be stronger and more reliable. However, ultrasonic welding may have limitations in thickness. Certain materials may not bond well. The user must consider the material characteristics and thickness before choosing this method.

Mechanical joining methods, such as screws or bolts, require additional hardware. This adds weight and complexity to the assembly. In contrast, ultrasonic welding creates a seamless joint. Still, there are challenges. Equipment calibration is essential for consistent quality. Improper settings can lead to weak joints and production issues. Careful planning is necessary to maximize the benefits of ultrasonic welding.

The future of ultrasonic welding machine development holds numerous prospects. With the rise of automation, machines are expected to become more intelligent. Equipped with AI technology, they will analyze welding parameters in real-time. This ensures better quality control and efficiency.

As industries evolve, the demand for lightweight and durable materials rises. Ultrasonic welding will adapt to join advanced composites and thermoplastics. However, challenges persist in achieving the ideal bond strength. Engineers will need to experiment with different frequencies and amplitudes to perfect this process. Short-term trials may lead to inconsistent results, requiring ongoing refinement.

Sustainability is another trend shaping machine design. Companies seek eco-friendly methods to reduce waste. Innovations such as energy-efficient systems and recyclable materials will gain traction. Yet, integrating these elements may complicate the current manufacturing workflow. The balance between innovation and practicality remains a significant hurdle for developers.