Leave Your Message

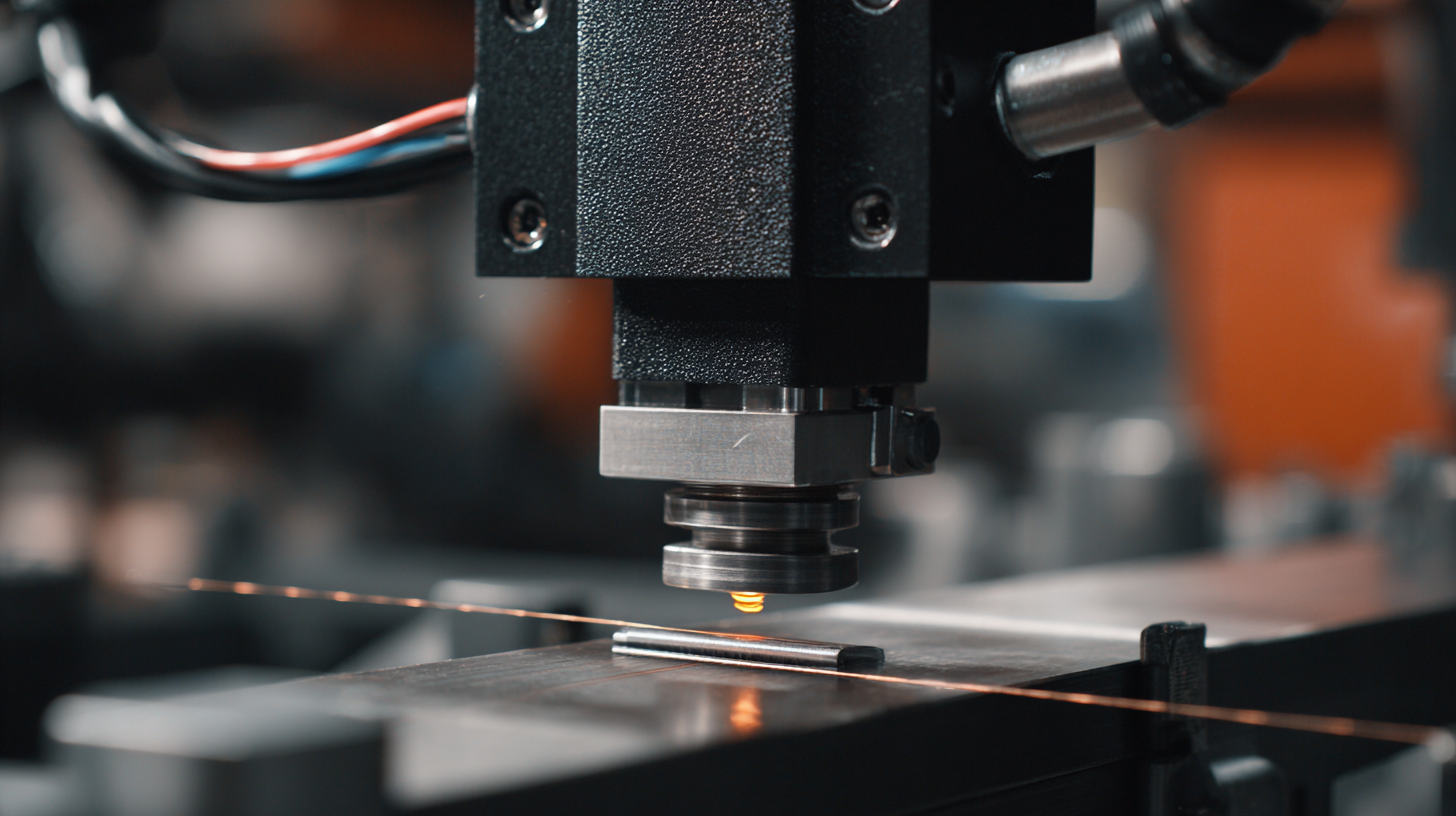

In the fast-evolving landscape of modern manufacturing, the adoption of advanced welding techniques is crucial for enhancing productivity and efficiency. Among these innovations, the Black Ultrasonic Welder has emerged as a game-changer, primarily due to its ability to deliver high-quality welds with minimal energy consumption.

According to a report by the International Society of Automation, ultrasonic welding is projected to grow at a CAGR of 6.8% from 2021 to 2028, driven by increasing demand for lightweight materials and the technological advancements in automated welding systems.

The Black Ultrasonic Welder, specifically designed to optimize the welding process for various applications, not only improves the quality of the weld but also reduces cycle time, resulting in significant cost savings.

This comprehensive guide explores the myriad advantages of using Black Ultrasonic Welders in contemporary manufacturing environments, highlighting their role in promoting efficiency and sustainability.

The Black Ultrasonic Welder, specifically designed to optimize the welding process for various applications, not only improves the quality of the weld but also reduces cycle time, resulting in significant cost savings.

This comprehensive guide explores the myriad advantages of using Black Ultrasonic Welders in contemporary manufacturing environments, highlighting their role in promoting efficiency and sustainability.

The evolution of ultrasonic welding technology plays a crucial role in modern manufacturing by enhancing the efficiency and performance of metal joining processes. Unlike traditional welding techniques, ultrasonic welding harnesses high-frequency vibrations to create a strong bond between materials without the need for additional adhesives or heat. Recent industry reports indicate a growing metal joining services market driven by sectors like aerospace, automotive, and packaging, where speed and precision are paramount.

As manufacturers increasingly adopt advanced technologies, the integration of ultrasonic welding demonstrates significant advantages. For instance, the use of rotary ultrasonic horns has been shown to improve the bonding quality and reduce production times. Additionally, innovative monitoring techniques, such as employing thin film sensors, are aiding in the assessment of weld integrity in real time, thus enhancing operational safety and reliability.

**Tips:** When considering ultrasonic welding for your manufacturing processes, explore detailed case studies to understand how similar industries have benefited. Also, keep an eye on advancements in digital twin technology, which can provide insights into optimization opportunities for your welding processes. Embracing these technologies not only saves time but potentially lowers costs while improving product quality.

In modern manufacturing, black ultrasonic welders stand out for their ability to deliver speed, efficiency, and precision. These advanced welding systems utilize high-frequency sound waves to create strong bonds between materials, significantly reducing the time required for assembly. With rapid cycle times, manufacturers can increase production rates while ensuring consistency and quality in their products.

Tips for maximizing the benefits of black ultrasonic welders include regular maintenance to ensure optimal performance and integrating these welders into an automated production line. This not only enhances speed but also allows for real-time monitoring of the welding process, minimizing the chance of defects.

Another crucial tip is to select the appropriate ultrasonic frequency for your specific materials. Understanding the properties of the materials being welded can significantly affect the efficiency and precision of the weld. By aligning the frequency with the material's characteristics, manufacturers can optimize the welding process and achieve superior bond strength.

| Dimension | Description | Benefits |

|---|---|---|

| Speed | Ultrasonic welding significantly reduces cycle times. | Increased production output and capacity. |

| Efficiency | Utilizes high-frequency vibrations to join materials. | Lower energy consumption and waste generation. |

| Precision | Ensures exact weld placement and minimal material distortion. | Improved product quality and reliability. |

| Versatility | Can be used on a wide range of thermoplastic materials. | Adaptable for various manufacturing settings. |

| Automation | Compatible with automated production lines. | Enhances operational efficiency and consistency. |

Ultrasonic welding has emerged as a groundbreaking technology in modern manufacturing, offering significant cost savings and impressive returns on investment (ROI) for industries across the board. One of the key benefits is the reduction in energy consumption compared to traditional welding methods.

Ultrasonic welders use high-frequency sound waves to create localized heat, allowing for effective joining of materials with minimal energy expenditure. This leads to lower operational costs over time, enhancing profitability for manufacturers who adopt this technology.

Ultrasonic welders use high-frequency sound waves to create localized heat, allowing for effective joining of materials with minimal energy expenditure. This leads to lower operational costs over time, enhancing profitability for manufacturers who adopt this technology.

Additionally, the efficiency of ultrasonic welding translates to decreased cycle times in production processes. By facilitating faster and more precise welds, companies can increase their output without compromising quality.

Industry data reveals that businesses implementing black ultrasonic welders have reported an average ROI of up to 30% within the first year. This remarkable financial impact, along with the reduced material waste associated with precise welding techniques, positions ultrasonic welding as a smart investment for manufacturers aiming to stay competitive in the evolving market landscape.

The modern manufacturing landscape is increasingly focused on sustainability, and black ultrasonic welders emerge as a key player in this shift. These advanced welding systems not only enhance production efficiency but also minimize environmental impact. Recent studies indicate that ultrasonic welding can reduce energy consumption by up to 50% compared to traditional welding methods. This significant reduction is crucial in light of the growing demand for energy-efficient technologies in manufacturing processes.

When considering environmental impacts, black ultrasonic welders offer a unique advantage in waste reduction. Reports from industry experts highlight that ultrasonic welding generates minimal waste materials due to its clean, localized process. In addition, these welders often use less energy, as they operate at lower temperatures, which further lowers greenhouse gas emissions. Opting for black ultrasonic welders aligns with sustainable manufacturing practices, making it a win-win for companies looking to enhance their green credentials.

Tip: To maximize the sustainability benefits of black ultrasonic welders, manufacturers should implement regular maintenance practices. This not only prolongs the lifespan of the equipment but also ensures optimal performance and energy efficiency.

Tip: Consider investing in a lifecycle assessment for your welding processes. Analyzing the environmental impact of various welding methods can help identify areas for improvement and reinforce your commitment to sustainable manufacturing.

The adoption of black ultrasonic welders has proven transformative across various sectors, evidenced by numerous successful case studies. In the automotive industry, for instance, manufacturers have harnessed these advanced welders to join components more efficiently, resulting in reduced assembly times and improved product strength. By integrating black ultrasonic welding technology, one major car manufacturer reported a 30% decrease in labor costs while simultaneously enhancing the durability of their vehicles.

Similarly, the electronics sector has embraced black ultrasonic welding for assembling intricate components in smartphones and other devices. A notable case involved a leading electronics firm that implemented this welding technology to secure delicate wiring harnesses. This shift not only increased production speed by 25%, but also led to a significant improvement in quality control, as the precision of black ultrasonic welds minimized defects and enhanced overall product reliability.

These examples illustrate how embracing black ultrasonic welders can yield substantial benefits, driving efficiency and innovation in modern manufacturing processes.