Leave Your Message

In the realm of modern manufacturing, efficiency and precision are paramount, particularly in processes involving the welding of materials. Among the innovative technologies available today, the Ultrasonic Card Slab Welder stands out as a pivotal tool designed to enhance fabrication capabilities across various industries. This advanced welding technique utilizes high-frequency ultrasonic vibrations to create strong, durable bonds between materials, significantly improving production speeds while maintaining exceptional quality.

By adopting the Ultrasonic Card Slab Welder, manufacturers can experience a plethora of advantages, from reduced energy consumption to the minimization of thermal damage during the welding process. This efficiency not only streamlines operations but also contributes to a more sustainable manufacturing environment. Furthermore, the Ultrasonic Card Slab Welder's ability to merge diverse materials seamlessly opens up a world of possibilities in product design and innovation. As industries continue to seek improved methods for fabrication, the importance of incorporating cutting-edge technology like the Ultrasonic Card Slab Welder cannot be overstated, making it an essential asset for any forward-thinking manufacturing operation.

Ultrasonic card slab welding technology is revolutionizing the fabrication industry with its numerous advantages. This method employs high-frequency ultrasonic sound waves to create a strong bond between materials without the need for additional adhesives or heat. According to a recent industry report by MarketsandMarkets, the ultrasonic welding market is expected to grow from $3.29 billion in 2020 to $4.41 billion by 2025, highlighting the increasing adoption of this technology across various sectors such as automotive, electronics, and medical devices.

One of the most significant benefits of ultrasonic welding is its efficiency. Research indicates that this technique can significantly reduce cycle times by up to 30% compared to traditional welding methods. This efficiency not only speeds up production processes but also minimizes material waste, contributing to more sustainable manufacturing practices. Furthermore, ultrasonic welding produces clean and precise joints, which enhances product quality and reduces the likelihood of defects. In a study conducted by the American Welding Society, ultrasonic welding was found to produce joints with a tensile strength 20% greater than that of conventional welding techniques, thereby ensuring durability and reliability in the final products.

In addition to its technical advantages, ultrasonic welding supports greater design flexibility. The ability to weld intricate shapes and sizes expands the possibilities for product innovation. Industries can utilize this technology to create lightweight and compact designs that meet evolving consumer demands. As manufacturers increasingly prioritize not only performance but also sustainability and design efficiency, ultrasonic card slab welding stands out as a pivotal solution, reinforcing its position as a preferred choice for modern fabrication needs.

The use of ultrasonic card slab welders in fabrication processes has redefined efficiency and speed, particularly in industries that require high precision and rapid production times. The technology operates by applying high-frequency ultrasonic vibrations to materials, which causes them to heat up and bond without the need for additional adhesives. This method not only accelerates the welding process but also enhances the structural integrity of the final product, leading to fewer defects and the need for rework. As a result, manufacturing lines can achieve increased throughput, transforming the pace at which products are delivered to the market.

Moreover, ultrasonic welding significantly reduces the energy consumption typically associated with traditional welding methods. Since the process is completed in mere seconds, it minimizes downtime and maximizes the overall efficiency of fabrication operations. The reduced cycle times allow companies to respond more swiftly to customer demands and changes in market conditions. This adaptability, combined with the consistent quality that ultrasonic welding offers, positions manufacturers to leverage cutting-edge fabrication techniques that improve their competitive edge while fostering innovation in product development.

| Advantage | Description | Impact on Fabrication |

|---|---|---|

| Increased Speed | Utilizes high-frequency ultrasonic waves to bond materials quickly. | Reduces production time significantly. |

| Energy Efficiency | Requires less energy compared to traditional welding processes. | Lowers operational costs and reduces carbon footprint. |

| Precision Welding | Allows for precise control over the welding parameters. | Ensures high-quality welds with minimal defects. |

| Versatility | Can be used on a variety of materials including plastics and metals. | Widens the range of applications in fabrication. |

| Minimal Heat Affected Zone | Generates less heat, preventing thermal damage to materials. | Preserves the integrity of heat-sensitive components. |

The reduction of material waste during the fabrication process is a significant advantage of utilizing an ultrasonic card slab welder. Traditional welding methods often lead to excess scrap due to their reliance on heat, which can weaken the integrity of the materials being worked on. In contrast, ultrasonic welding employs high-frequency sound waves to create a solid-state bond without the need for extensive thermal application. As a result, less material is compromised during the joining process, significantly minimizing waste. This efficiency not only bolsters the cost-effectiveness of production but also contributes to more sustainable practices within the manufacturing sector.

Moreover, the precision offered by ultrasonic technology allows for the joining of smaller and more intricate components without the need for additional fasteners or adhesives. Traditional methods can often require considerable post-processing to clean up any excess material or to ensure the quality of the bond. In contrast, the clean and efficient nature of ultrasonic welding reduces the likelihood of material overhead. By focusing on exact placements and creating strong bonds with minimal excess, manufacturers can further enhance their resource management while maintaining product quality. This approach aligns with modern manufacturing goals of reducing waste and maximizing efficiency, proving that the ultrasonic card slab welder is a pivotal tool in optimizing the fabrication process.

The use of ultrasonic card slab welders has revolutionized the fabrication industry by significantly enhancing the quality and precision of welds. According to a recent industry report, companies utilizing ultrasonic welding technology have observed a decrease in defect rates by up to 30% compared to traditional welding methods. This improvement can be attributed to the precise control of heat and force, allowing for optimal joint formation without compromising the integrity of the materials being joined. Such advancements not only result in stronger welds but also minimize post-weld finishing processes, further streamlining production.

Furthermore, ultrasonic welding ensures consistent results across batches, leading to greater reliability in manufactured products. A study conducted by the International Institute of Welding highlighted that precision welding reduces material fatigue, extending the lifespan of components and enhancing overall product safety. As industries move towards automated solutions, the incorporation of ultrasonic technology also facilitates real-time quality monitoring, ensuring each weld meets stringent quality standards.

**Tip:** When considering ultrasonic welding systems, evaluate your material compatibility to maximize the benefits of this technology. Different materials may respond uniquely to ultrasonic methods, impacting weld quality. Additionally, regularly calibrating your welding equipment can help maintain precision and efficiency over time.

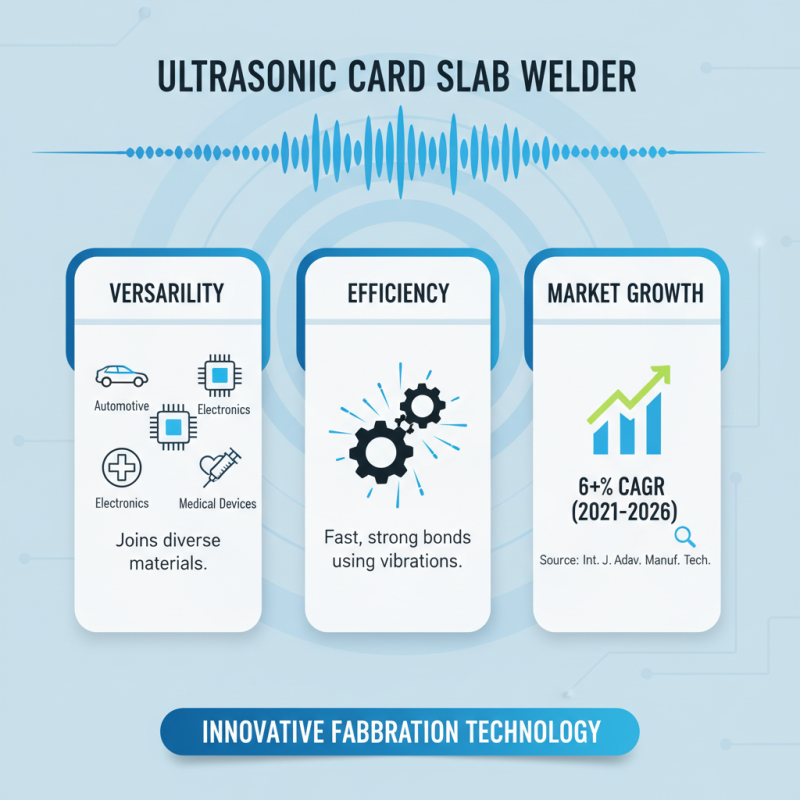

The ultrasonic card slab welder has gained significant traction across various industries due to its unmatched versatility and efficiency in fabrication processes. This innovative technology utilizes high-frequency vibrations to create strong bonds between materials, making it an ideal choice for applications in sectors such as automotive, electronics, and medical devices. According to a report by the International Journal of Advanced Manufacturing Technology, the ultrasonic welding market is projected to grow at a CAGR of over 6% from 2021 to 2026, underscoring the increasing adoption of this technology in diverse applications.

In the automotive industry, ultrasonic welding is utilized for joining plastic components, enabling manufacturers to optimize assembly processes and reduce cycle times. A study conducted by the Society of Manufacturing Engineers highlights that implementing ultrasonic welding can lead to a 30% increase in production efficiency compared to traditional welding methods. Similarly, in the electronics sector, this welding technique plays a crucial role in the assembly of circuit boards and battery packs, providing a reliable solution that minimizes thermal damage to sensitive components. The versatility of ultrasonic card slab welders extends to the medical field as well, where they ensure the integrity and sterility of devices used in patient care, as evidenced by a report from the Medical Device and Diagnostic Industry, which states that 45% of medical device manufacturers are now employing ultrasonic welding techniques to enhance product quality.