Leave Your Message

The modern manufacturing landscape is rapidly evolving, driven by technological innovations and a growing emphasis on sustainability. Among these advancements, Green Ultrasonic Welder technology stands out as a game-changer, offering a range of benefits that revolutionize traditional welding processes. This technology not only enhances efficiency and precision in manufacturing but also significantly reduces energy consumption and waste production.

By embracing this cutting-edge technology, businesses can achieve sustainable growth while meeting the demands of an eco-conscious market.

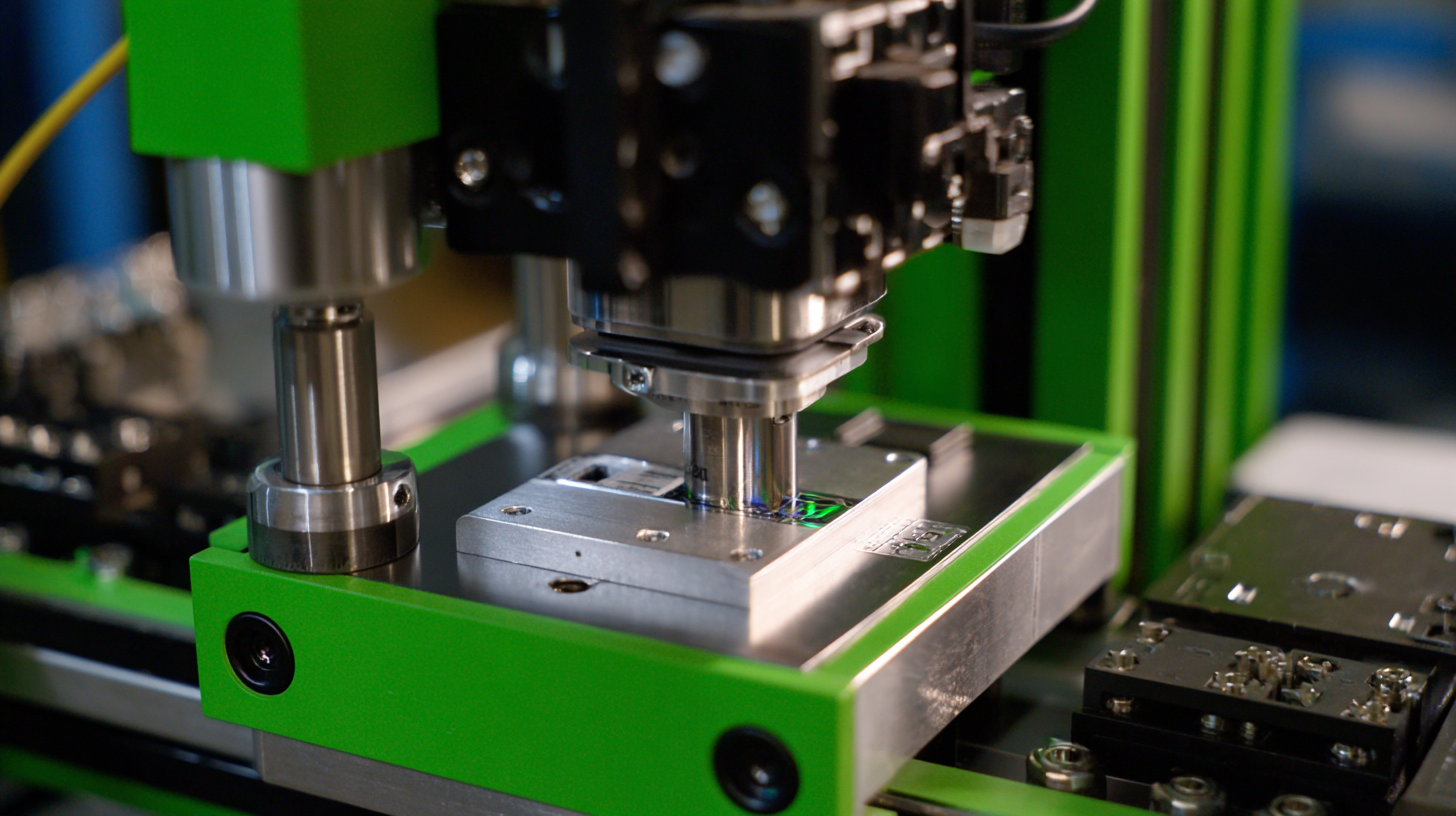

The innovative features of green ultrasonic welder technology are revolutionizing modern manufacturing by enhancing efficiency while minimizing environmental impact. Unlike traditional welding methods, which often require adhesives or additional heating processes, ultrasonic welding leverages high-frequency sound waves to join materials rapidly. According to a recent industry report by MarketsandMarkets, the ultrasonic welding market is expected to grow at a CAGR of 8.2% from 2022 to 2027, showcasing the rising adoption of this eco-friendly technology in diverse sectors, including automotive and electronics.

One of the key advantages of green ultrasonic welders is their ability to significantly reduce energy consumption. Traditional methods often consume up to 60% more energy, while ultrasonic welding systems operate at remarkably lower power levels, achieving effective welds in a fraction of the time. This not only leads to cost savings but also aligns with sustainability goals. Additionally, the use of ultrasonic welding minimizes material waste, as it can effectively bond dissimilar materials without the need for fillers or extra components.

**Tips:** When integrating green ultrasonic welder technology into your production process, consider investing in training for your staff to maximize efficiency and ensure optimal results. Regular maintenance and updates to your equipment can also enhance performance. Lastly, explore partnerships with suppliers specializing in eco-friendly materials to complement your new welding capabilities.

Green ultrasonic welding technology is emerging as a game-changer in the modern manufacturing landscape, particularly due to its significant potential for environmental impact reduction. Traditional welding methods often involve substantial energy consumption and generate a considerable amount of emissions. Conversely, ultrasonic welding utilizes high-frequency sound waves to create a solid-state bond between materials, minimizing energy use by up to 80% compared to conventional techniques. According to a recent report by the International Council on Clean Transportation, the adoption of green manufacturing technologies like ultrasonic welding could decrease carbon emissions in the manufacturing sector by nearly 30% over the next decade.

Furthermore, the use of ultrasonic welding reduces waste generation substantially. Unlike traditional methods that involve cutting and machining, ultrasonic welding produces zero fumes and minimal scrap, making it a cleaner and more sustainable option. A study conducted by the Institute of Electrical and Electronics Engineers revealed that industries implementing ultrasonic welding have reported a 40% reduction in material waste, emphasizing its potential for enhancing resource efficiency.

Tips: When considering the transition to green ultrasonic welding, manufacturers should evaluate not only the immediate cost savings but also the long-term environmental benefits. Implementing training programs for staff on the proper usage of ultrasonic technology can further maximize efficiency and extend equipment lifespan, enhancing sustainability efforts in the manufacturing process.

The transition to green technologies in manufacturing has sparked significant interest in

ultrasonic welding, particularly due to its cost efficiency and energy savings. Recent studies indicate that energy-efficient ultrasonic welders can operate effectively in confined spaces while accommodating conductor cross-sections ranging from 10 to 95 mm². This capability is increasingly important in industries driven by the rise of electromobility, as manufacturers seek reliable and sustainable welding solutions. By adopting green ultrasonic welding techniques, companies can considerably reduce energy consumption, potentially lowering operational costs by up to 40%, based on industry analysis.

Moreover, advancements in ultrasonic welding technology align with the increasing need for sustainable practices in battery production and electric vehicle manufacturing. For instance, innovative processes being developed for battery cell production are making manufacturing more economical while minimizing environmental impact. As the industry shifts towards greener options, embracing technologies like ultrasonic welding not only ensures compliance with environmental regulations but also positions companies to benefit from the growing demand for energy-efficient solutions. Overall, the strategic implementation of green ultrasonic welders represents a critical step toward fostering a more sustainable manufacturing landscape.

Ultrasonic welder technology has emerged as a transformative force across various industries, with applications ranging from automotive manufacturing to the production of medical devices. According to a report by Technavio, the global ultrasonic welding market is expected to grow by over 5% annually, reaching approximately $2.5 billion by 2025. This growth is driven by the technology's ability to join materials quickly and efficiently, reducing production time and energy consumption—factors crucial in today's competitive manufacturing landscape.

In the automotive industry, ultrasonic welding is utilized for assembling components like sensors and electronic parts, ensuring durable joins that meet strict safety standards. Furthermore, in the medical field, this technology is essential for creating sterile and precise seals in devices such as syringes and IV bags, as highlighted by a study from MarketsandMarkets which suggests that the medical segment alone could account for nearly 30% of ultrasonic welding market share by the end of 2023. The versatility and reliability of ultrasonic technology not only enhance production efficiency but also contribute to sustainability efforts, as the process minimizes waste and the need for harmful adhesives.

As industries increasingly prioritize sustainability, green technology is becoming a cornerstone of modern manufacturing. The advancements in ultrasonic welding technology exemplify this trend. This method not only enhances production efficiency but also reduces energy consumption and waste, making it an eco-friendly option. Businesses are now turning to ultrasonic welding for its ability to bond materials without the need for additional adhesives or solvents, streamlining the manufacturing process while minimizing environmental impact.

**Tips:** When considering implementing ultrasonic welding technology, focus on training your staff to operate the machinery efficiently and understand the environmental benefits. Additionally, look for suppliers who prioritize sustainable materials to maximize the green impact of your production processes.

Future trends indicate that advancements in green technology will lead to even more sophisticated ultrasonic welding techniques. Innovations such as AI integration for predictive maintenance and the use of renewable energy sources to power ultrasonics are on the horizon. These developments may not only enhance the capabilities of manufacturing processes but also align them further with the global sustainability goals to reduce carbon footprints significantly.

**Tips:** Stay updated on emerging technologies and trends in the ultrasonic welding field by attending relevant workshops and webinars. Networking with other professionals can provide insights into best practices and innovations that could elevate your manufacturing processes.