Leave Your Message

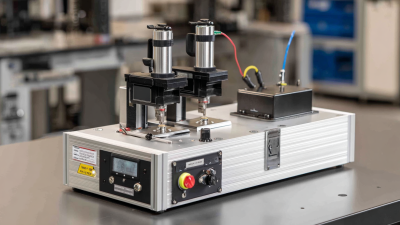

In today's fast-paced manufacturing landscape, the use of advanced technologies like ultrasonic welding is crucial. Experts recognize the need for efficiency and precision in production processes. John Smith, a leading expert in the field of ultrasonic welding, states, "Investing in an Ultrasonic Welder For Hire can transform your project outcomes."

Employing an Ultrasonic Welder For Hire offers a range of advantages, particularly for industries focused on high-quality results. This technology reduces material waste and enhances production speed. Moreover, the versatility in joining different materials makes it a valuable option for various applications. Each project can benefit from unique techniques tailored to its specific requirements.

However, not all ultrasonic welding services deliver the same quality. Companies must evaluate expertise and technology when hiring. Identifying a skilled provider can make a significant difference. Projects can sometimes face challenges with inconsistent results if the hiring decision is rushed. Thus, careful selection of an Ultrasonic Welder For Hire is essential for achieving desired project outcomes.

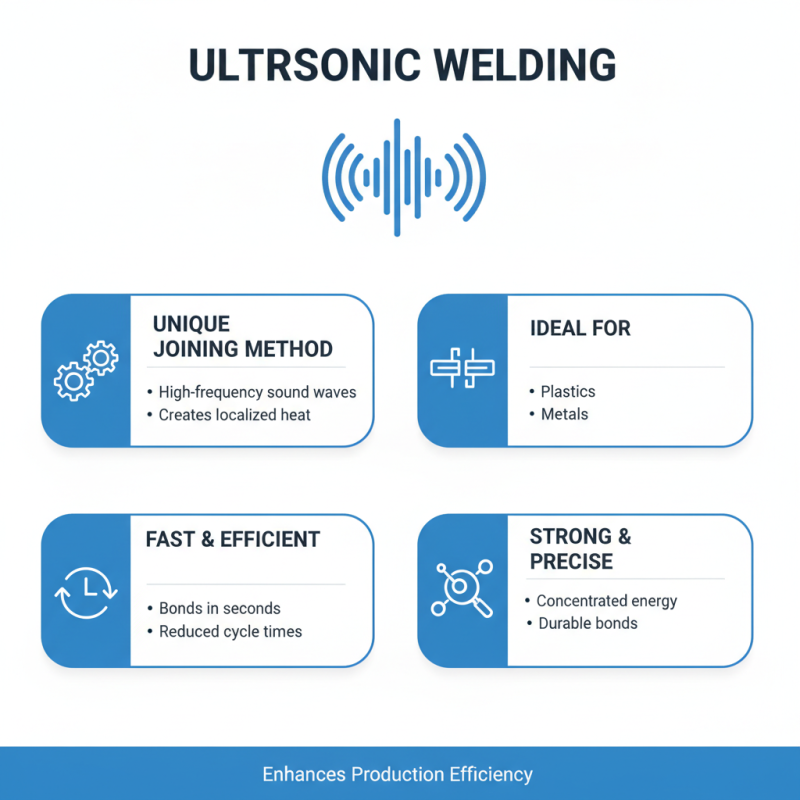

Ultrasonic welding is a unique joining method. It uses high-frequency sound waves to create heat. This process is especially effective for plastics and metals. By concentrating energy on a small area, it achieves strong bonds in seconds. This speed is invaluable in high-demand production environments. It reduces cycle times and enhances efficiency dramatically.

Applications of ultrasonic welding abound across various industries. Automotive manufacturers utilize this method for interior components. Medical device companies also find it crucial for assembling small parts without compromising sterility. Despite its benefits, there are challenges. Some materials don't bond well under ultrasonic conditions. It's essential to understand the material properties before proceeding. Improper setup can lead to weak joints, ultimately costing time and resources.

Ultrasonic welding is revolutionizing manufacturing processes. This technique uses high-frequency sound waves to create strong bonds between materials. The speed and efficiency of this method are remarkable. Projects that once took hours can now be completed in minutes.

One key advantage is the precision it offers. Ultrasonic welding targets specific areas, reducing waste and preserving material integrity. This can lead to significant cost savings. Additionally, the process is clean. There are no toxic fumes or chemicals involved, making it safer for workers.

When considering ultrasonic welding, think about your project needs. Assess the materials being joined to ensure compatibility. It's also vital to understand the scale of production. For smaller jobs, this method might not be the best fit. Keep an eye on the learning curve. Training might be necessary for effective usage.

Overall, the precision, efficiency, and safety of ultrasonic welding present compelling reasons for its adoption in manufacturing. Embrace the advantages, but remain aware of the gaps in knowledge and training that might arise.

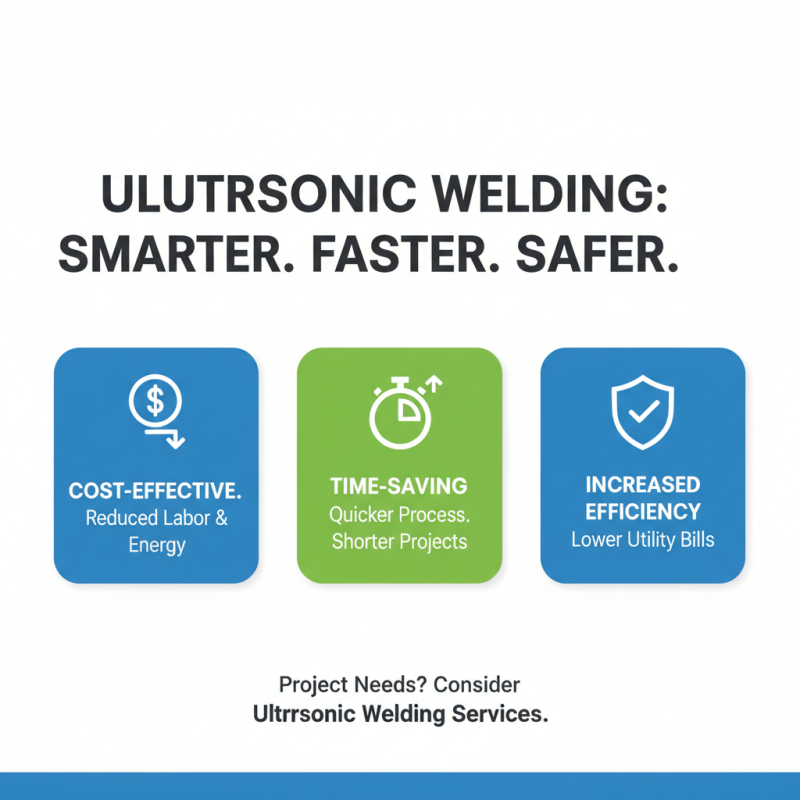

When considering project needs, cost-effectiveness is a critical factor. Hiring ultrasonic welding services can offer significant savings. Traditional welding methods often require extensive labor and time. Ultrasonic welding, however, minimizes these costs. The process is quicker, reducing project timelines. It also requires less energy, which can lead to lower utility bills.

Moreover, ultrasonic welding produces minimal waste. This not only cuts material costs but also aligns with sustainable practices. Companies increasingly seek eco-friendly solutions. Therefore, employing ultrasonic welders can meet both budgetary and environmental goals. The upfront investment may seem daunting, but the long-term savings often outweigh initial expenses.

Yet, it's crucial to recognize potential drawbacks. Miscommunication about project requirements can lead to inefficiencies. Not every product may suit ultrasonic welding. Factors like material compatibility must be evaluated. In an era of rapid technological change, staying informed is essential. Balancing cost, quality, and technology isn’t easy but is vital for project success.

Ultrasonic welding technology offers significant enhancements in product quality. This method uses high-frequency sound waves to create strong, durable bonds between materials. It is particularly effective for plastic components. The result is often a tighter seal and improved overall integrity.

One key benefit is the precision of the welds. A well-executed weld can minimize the risk of defects. However, improper settings can lead to weak joints. Attention to detail in the setup process is crucial. Workers must understand the specific requirements of each project. Proper training can reduce errors and improve outcomes.

Additionally, ultrasonic welding helps streamline production processes. It is often faster than traditional methods, reducing labor costs. However, investing in ultrasonic systems can pose challenges. Not all projects may justify the initial expense. Evaluating the long-term benefits is essential. Overall, ultrasonic welding presents unique opportunities and complexities for enhancing product quality.

Ultrasonic welding is gaining popularity for a reason. One key benefit is its low environmental impact. This technique uses high-frequency sound waves to create bonds, often requiring no additional materials. As a result, there is less waste compared to traditional welding methods. It’s a more sustainable option for manufacturers focused on reducing their carbon footprint.

However, the environmental benefits of ultrasonic welding are not without challenges. Some processes still rely on energy-intensive machinery, which can have a large carbon footprint. Companies must evaluate their energy sources to maximize the technique's eco-friendliness. Additionally, there are considerations regarding the materials used in ultrasonic welding. Not all plastics are recyclable, which undermines the potential benefits.

This technique also has limited applications in some industries. Certain complex assemblies may not work well with ultrasonic welding due to material constraints. Companies must weigh these factors against the potential ecological advantages. It's essential to strike a balance between innovation and sustainability in every project. The path forward requires reflective thinking on how to minimize environmental impact while maximizing efficiency.