Leave Your Message

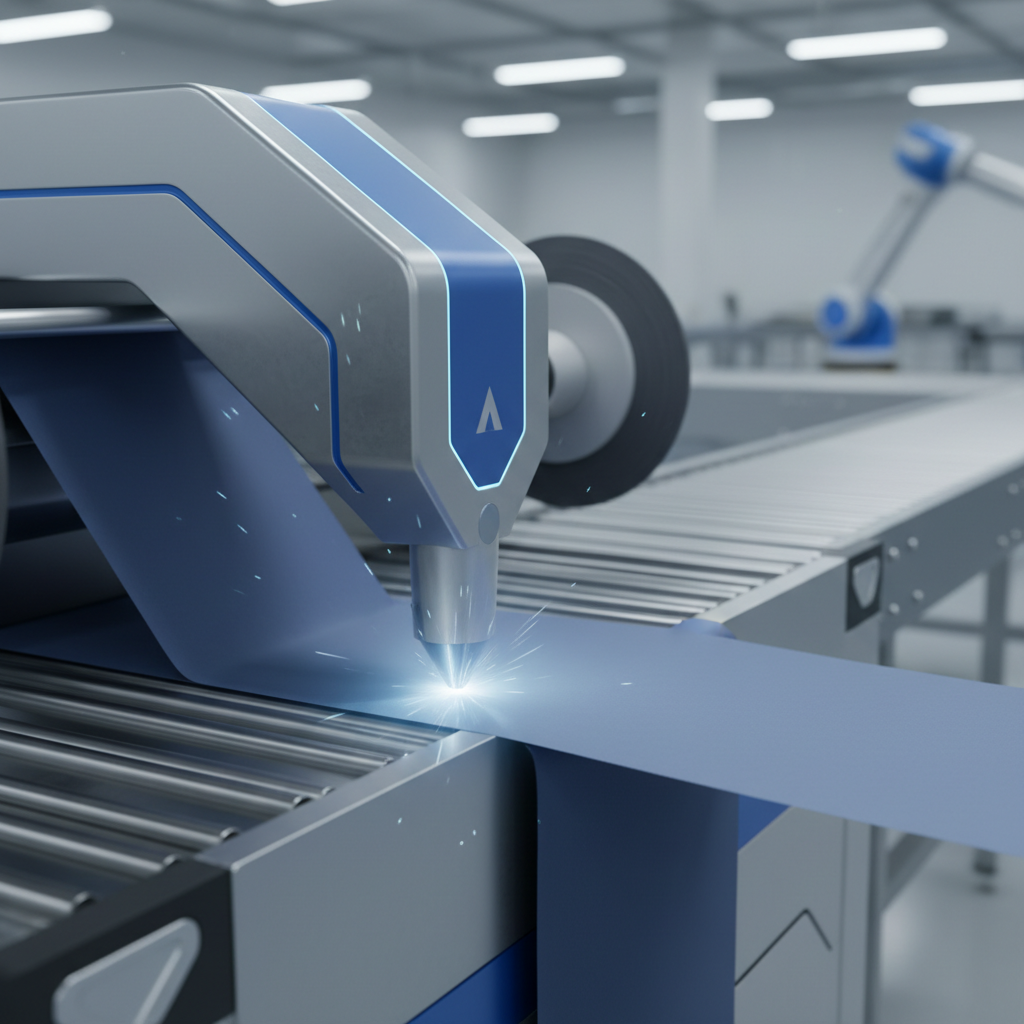

In the rapidly evolving landscape of manufacturing technology, the

Ultrasonic Fabric Welder stands out as a

groundbreaking solution that addresses the demands for seamless, efficient production processes. As noted

by industry expert Dr. Emily Chen, a leading figure in textile engineering, "The Ultrasonic

Fabric Welder not only enhances the quality of seams but also significantly reduces production time and

material waste." This powerful tool leverages ultrasonic frequencies to create strong, durable joins

without the need for traditional stitching, making it a game-changer for various sectors, including

apparel, automotive, and medical textiles.

The benefits of employing an Ultrasonic Fabric Welder are manifold,

as manufacturers are increasingly recognizing its capabilities to streamline operations and improve product output.

From cost savings to superior performance, the advantages extend beyond mere efficiency. In this analysis, we

will explore the top ten benefits of using an Ultrasonic Fabric Welder

for seamless manufacturing, highlighting how this innovative technology is set to define the future of the

fabric industry. As we delve deeper, it becomes clear that embracing this technology is not just a trend

but a necessary step towards sustainable and advanced manufacturing practices.

Ultrasonic technology has transformed the landscape of seamless fabric welding, offering numerous advantages that cater to the evolving needs of the textile industry. One of the primary benefits is the enhanced efficiency it brings to manufacturing processes. According to a recent report by MarketsandMarkets, the ultrasonic welding market is projected to reach $4.2 billion by 2025, driven by its ability to minimize cycle times and increase throughput without compromising quality. This technology welds materials in mere seconds, significantly reducing labor costs and improving production speed.

In addition to efficiency, ultrasonic fabric welding enhances the quality of seams produced. Unlike traditional sewing methods, which can lead to fraying and weak joints, ultrasonic welding creates smooth, airtight seams that are both durable and reliable. A study conducted by the Institute of Textile Technology highlighted that fabrics joined by ultrasonic welding exhibit a significantly higher tensile strength, with joint strengths up to 30% greater than those achieved through conventional sewing. This ensures that products not only meet stringent quality standards but also enhance the end-user experience by providing seamless and comfortable materials.

The adoption of ultrasonic fabric welders in manufacturing processes significantly enhances production speed, a crucial factor in today's competitive market. Unlike traditional sewing methods, ultrasonic welding uses high-frequency vibrations to join fabrics together, resulting in nearly instantaneous bonding. This rapid process reduces the time needed for assembly, allowing manufacturers to accelerate their workflow and increase overall output. As a result, companies can meet tight deadlines and respond more effectively to consumer demands without compromising quality.

In addition to speed, ultrasonic fabric welding minimizes the need for additional materials such as thread or adhesives, further streamlining the production line. The elimination of these components not only cuts costs but also reduces waste, aligning manufacturing practices with sustainability goals. Moreover, the precision of ultrasonic welders ensures strong and durable seams, enhancing the final product's quality. Overall, leveraging ultrasonic technology transforms manufacturing efficiency, making it an indispensable tool for businesses aiming to thrive in a fast-paced environment.

| Benefit | Description | Impact |

|---|---|---|

| Enhanced Production Speed | Ultrasonic welding significantly reduces cycle times, enabling faster manufacturing processes. | Increased throughput and reduced lead times. |

| Cost Efficiency | Lower energy consumption and reduced material waste help decrease production costs. | Improved profit margins. |

| Seamless Joints | Creates strong, seamless fabric joints without the need for adhesives oradditional materials. | Better product quality and durability. |

| Versatility | Can be used on various fabrics and materials, from lightweight to heavy-duty applications. | Allows for diverse product offerings. |

| Reduced Labor Costs | Automation of the welding process lowers the need for manual labor. | Reduces operational costs. |

| Minimal Heat Impact | The process generates minimal heat, preventing fabric damage and ensuring integrity. | Higher quality products. |

| Environmentally Friendly | Reduces the need for solvents and adhesives, making it a greener option. | Supports sustainability goals. |

| Consistency and Quality Control | Precision welding ensures uniform results with minimal variations. | Enhanced product reliability. |

| Simplified Processes | Reduces the number of steps involved in the manufacturing process. | Streamlined production workflows. |

| Long-Term Investment | Durable equipment and processes that provide long-term savings. | Maximized return on investment. |

Ultrasonic welding has emerged as a transformative technology in the manufacturing sector, particularly noted for its cost efficiency. By utilizing high-frequency ultrasonic vibrations to bond materials, this method significantly reduces waste associated with traditional welding techniques. According to a report from the American Institute of Manufacturing Technologies, ultrasonic welding can reduce material waste by up to 90% in certain applications, particularly in the textiles and nonwoven industries. This not only minimizes costs associated with excess materials but also enhances sustainability by lowering the environmental impact.

In addition to minimizing waste, ultrasonic welding helps streamline production processes, leading to lower overall material costs. Manufacturers can achieve strong, durable seams without the need for additional adhesives or fasteners, which can often add to the expense. A recent study by the International Journal of Advanced Manufacturing Technology indicated that adopting ultrasonic welding can lead to cost savings of approximately 30% in material utilization compared to traditional welding methods. As the manufacturing industry continues to seek innovative ways to enhance efficiency and sustainability, ultrasonic welding stands out as a viable solution that directly addresses both economic and ecological concerns.

Ultrasonic welding technology has revolutionized the manufacturing industry, particularly when it comes to enhancing seam strength and durability. This innovative process utilizes high-frequency sound waves to meld fabric layers at a molecular level, creating bonds that are not only strong but also resistant to wear and tear. By eliminating the need for traditional stitching methods, manufacturers can produce seamless products that boast improved performance in various applications, from automotive textiles to high-performance activewear.

When utilizing ultrasonic fabric welding, it's essential to consider the material properties being joined. For optimal results, choose compatible fabrics that can withstand the heat generated during the welding process. Fabrics like polyester and nylon have demonstrated excellent bonding capabilities, ensuring a secure, long-lasting seam. Additionally, ensure that the ultrasonic welding equipment is properly calibrated; even minor adjustments can significantly impact seam integrity.

Tip: Always conduct preliminary tests on small fabric samples to fine-tune settings before scaling up production. This practice not only saves time but also ensures that the final product meets quality standards. Moreover, regular maintenance of your ultrasonic welder will help maintain consistent performance and prolong the lifespan of the equipment, leading to better quality seams and overall efficiency.

Ultrasonic fabric welders have emerged as a transformative tool across various industries, providing unparalleled versatility in manufacturing processes. In sectors ranging from textiles to automotive, these welders facilitate seamless joining of materials without the need for traditional stitching or adhesives. This technology not only enhances production efficiency but also ensures a high-quality finish without compromising the integrity of the fabric. For example, in the medical industry, ultrasonic welding is widely adopted for producing sterile and secure seams in surgical gowns and drapes, meeting stringent safety standards.

Moreover, the adaptability of ultrasonic fabric welders means they can be employed in a variety of applications, including the creation of non-woven fabrics, technical textiles, and even in packaging solutions. Their ability to process different types of materials—such as synthetic fibers, thin films, and composites—makes them valuable in diverse sectors, including fashion, automotive upholstery, and protective gear manufacturing. This versatility allows manufacturers to innovate continually, responding quickly to market demands while maintaining cost-effectiveness and sustainability in their production processes.