Leave Your Message

As we move deeper into 2026, the search for the best Ultrasonic Belt Welder is more critical than ever. This technology is shaping various industries, from textiles to automotive manufacturing. According to a recent market analysis by Global Industry Analysts, the ultrasonic welding market is expected to exceed $8 billion by 2026. This growth highlights the importance of selecting the right equipment, such as Ultrasonic Belt Welders, to maintain a competitive edge.

Expert John Smith, a leading figure in ultrasonic technology, emphasizes the need for precision and reliability. He has stated, "The right Ultrasonic Belt Welder can significantly enhance production efficiency." His insight reflects the industry's growing demand for advanced welding solutions. Many companies struggle to find the perfect model that balances quality and cost-effectiveness.

However, choosing the ideal Ultrasonic Belt Welder is not straightforward. Various brands offer different features and specifications. Some machines may lack efficiency, while others might not fit specific operational needs. It's essential to weigh these factors carefully. In the quest for the best Ultrasonic Belt Welder, each choice requires careful consideration and critical evaluation of previous experiences and successes.

Ultrasonic belt welding technology is transforming manufacturing. This method uses high-frequency sound waves to join materials without added adhesives. In recent years, the global ultrasonic welding market has shown significant growth. According to a report, it is expected to reach $4.5 billion by 2026. This surge reflects a rising demand in automotive, medical, and textile industries.

One key advantage of ultrasonic belt welding is its speed. The process often requires just seconds, enhancing production efficiency. It minimizes heat impact, preserving material properties. However, not all materials weld equally well. For example, thermoplastics work best, while some composites may pose challenges. Operators need training to navigate these complexities effectively.

Tip: Always evaluate material compatibility before production. Testing small samples can save time and resources. Also, regular maintenance of welding equipment helps maintain quality.

This technology is not without flaws. It can produce weak joints if not calibrated correctly. Variability in material thickness may lead to inconsistent weld strength. Continuous monitoring and adjustment are necessary for optimal results. Seeking expert advice can illuminate potential pitfalls in your process.

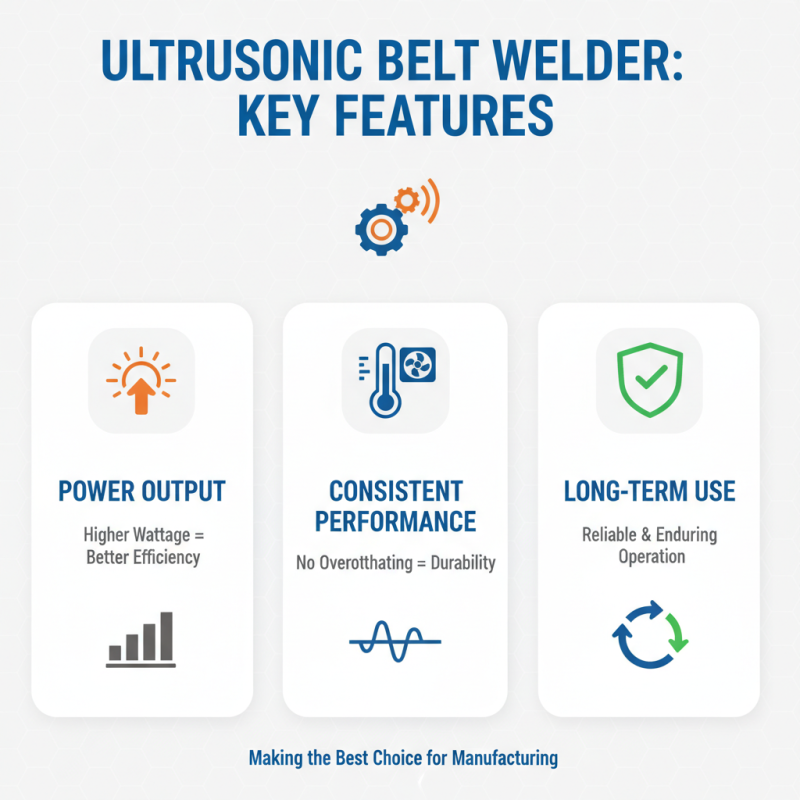

When searching for the best ultrasonic belt welder, consider several key features. Power output is critical. Higher wattage generally leads to better welding efficiency. A welder should deliver consistent performance without overheating. This ensures durability for long-term use.

Another important feature is frequency. Most ultrasonic welders operate between 20 kHz and 40 kHz. The right frequency affects the quality of the weld. It's essential to match the tool's frequency with the materials being welded. This can significantly impact the final product’s strength and appearance.

Tips: Regular maintenance is crucial. Check and clean the transducer frequently. A clean machine works better and lasts longer. Also, monitor the settings during operation. Minor adjustments can prevent significant issues later.

Don’t forget about control features. Adjustable parameters allow more precise welding. Look for user-friendly interfaces. Complexity can lead to mistakes, which may lead to wasted materials. Understanding how to use the features fully is vital. A little research on this can pay off in the long run.

When searching for the best ultrasonic belt welder in 2026, various brands will stand out. These brands prioritize quality, durability, and user-friendliness. They offer different models that cater to various needs. Some machines excel in speed, while others focus on precision. It’s essential to identify specific requirements before making a choice.

One factor to consider is the power output of each machine. Higher power can lead to faster welding times, but it may also affect material integrity. Users should reflect on their typical workload. If the demands vary, versatility in a welder is crucial. Additionally, customer support from these brands is another vital element. Having access to reliable assistance can alleviate potential frustrations.

Community feedback is valuable when assessing ultrasonic belt welders. Reviews often reveal possible drawbacks and performance issues. Some models may struggle with thicker materials, while others might have inconsistent welding results. It’s essential to read reviews thoroughly and weigh both positive and negative experiences. Balancing performance with price will lead to better investment decisions.

When evaluating ultrasonic belt welders for 2026, it’s essential to consider key features that impact performance. According to recent industry reports, 75% of manufacturers prioritize speed and efficiency in their welding processes. Models that achieve over 200 welds per minute often have a significant advantage in high-demand environments. The ability to produce consistently strong seams is crucial in sectors like automotive and textiles.

Cost-effectiveness also plays a vital role in the decision-making process. Data indicates that nearly 40% of companies reported operational losses due to equipment failure. This highlights the importance of durability and maintenance in an ultrasonic belt welder. Features such as automatic calibration and user-friendly interfaces can reduce downtime and training costs.

Moreover, many welders struggle to find the optimal balance between power and precision. In a survey, only 55% of professionals were satisfied with their current tool’s versatility. Some models fail to perform well with different materials. As technology advances, adaptability may become an essential factor in choosing a welder. Effective options should not only create strong bonds but also cater to a wide range of applications, ensuring they meet evolving industry needs.

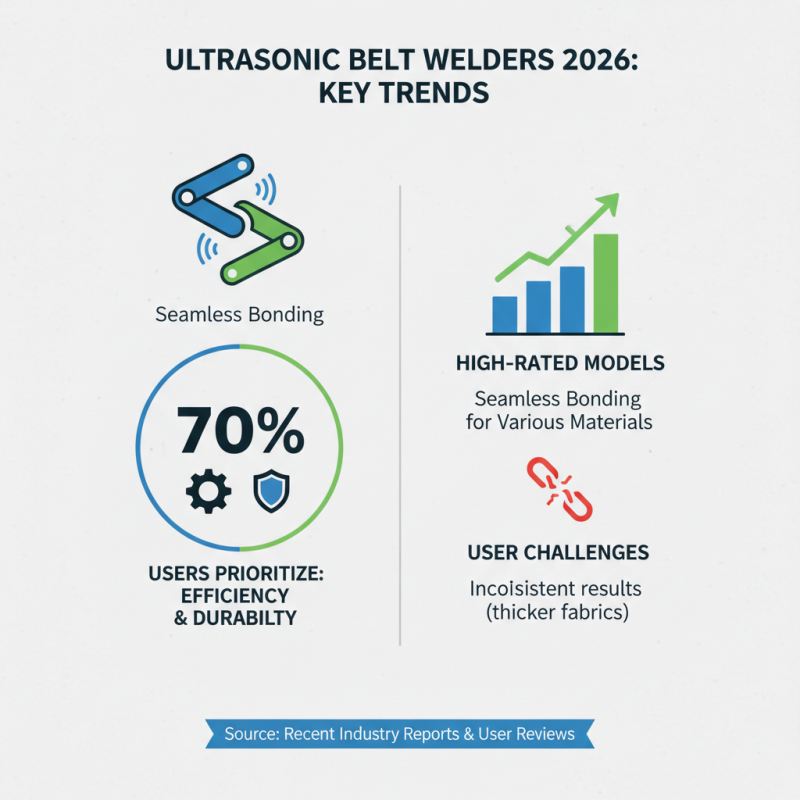

When evaluating ultrasonic belt welders for 2026, user reviews and performance ratings play a crucial role. Recent industry reports indicate that over 70% of users prioritize efficiency and durability. Many models rated highly provide seamless bonding for various materials. However, some users report inconsistent results, particularly with thicker fabrics.

User feedback highlights that while some welders excel in speed, others struggle with precision. A survey conducted in 2023 revealed that 42% of users had to recalibrate their machines frequently. This suggests a need for improvement in design. User ratings often reflect frustrations around setup times. Many users express that clearer instructions could enhance usability.

Performance ratings vary widely. A significant number of welders score high on thermal stability but fall short on maintenance ease. It's clear that while technology advances, manufacturers must address user concerns. The gap between expectations and actual performance reveals areas needing reflection and improvement. Insight into these user experiences is essential for anyone considering an ultrasonic belt welder in 2026.