Leave Your Message

In recent years, the demand for efficient and precise welding techniques has surged. Ultrasonic Spot Welders have emerged as a vital tool in various industries, particularly in electronics and automotive sectors. According to a recent market report, the ultrasonic welding equipment market is expected to reach $1.7 billion by 2025, growing at a CAGR of 6.5%. This growth highlights the increasing reliance on advanced welding technologies.

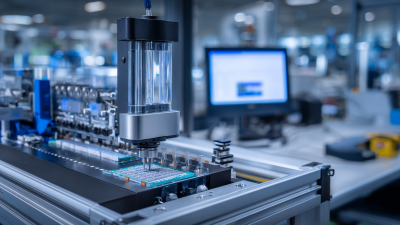

These welders work by applying high-frequency ultrasonic vibrations to materials, creating strong bonds without the need for additional adhesives. Their ability to provide a clean and durable weld is a significant advantage in manufacturing. However, selecting the right Ultrasonic Spot Welder can be daunting. With numerous models and specifications available, users must consider factors like power output, frequency, and material compatibility.

While the technology offers many benefits, it is not without challenges. Some users report issues with heat management and weld quality, sparking questions about their reliability. Addressing these concerns is crucial for maximizing the potential of Ultrasonic Spot Welders. Understanding the nuances of these tools is essential for making an informed purchase.

Ultrasonic spot welding technology has transformed the manufacturing process across various industries. This innovative technique uses high-frequency sound waves to join materials without the need for additional adhesives. The result is a strong, reliable bond that can withstand stress and strain. Many manufacturers prefer this method because it is efficient and precise.

One crucial component of this technology is the ultrasonic transducer, which converts electrical energy into mechanical vibration. The vibrations create localized heat, fusing materials together effectively. However, achieving optimal results can be tricky. Factors such as material thickness, surface cleanliness, and alignment can affect the welding outcome. A poorly aligned weld may lead to weak joints that compromise product integrity.

Despite its advantages, ultrasonic spot welding is not without challenges. Operators must undergo training to understand the nuances of the equipment and materials. Additionally, routine maintenance is often overlooked, which can lead to equipment malfunction. Regular reflection on the welding process is essential for improvement. Ultimately, a deep understanding of the technology can enhance product quality and manufacturing efficiency.

This bar chart displays the performance metrics of ultrasonic spot welders in the year 2026, showcasing their power, frequency, welding speed, and heat generated. These metrics are essential for evaluating the efficiency and effectiveness of ultrasonic welding technologies.

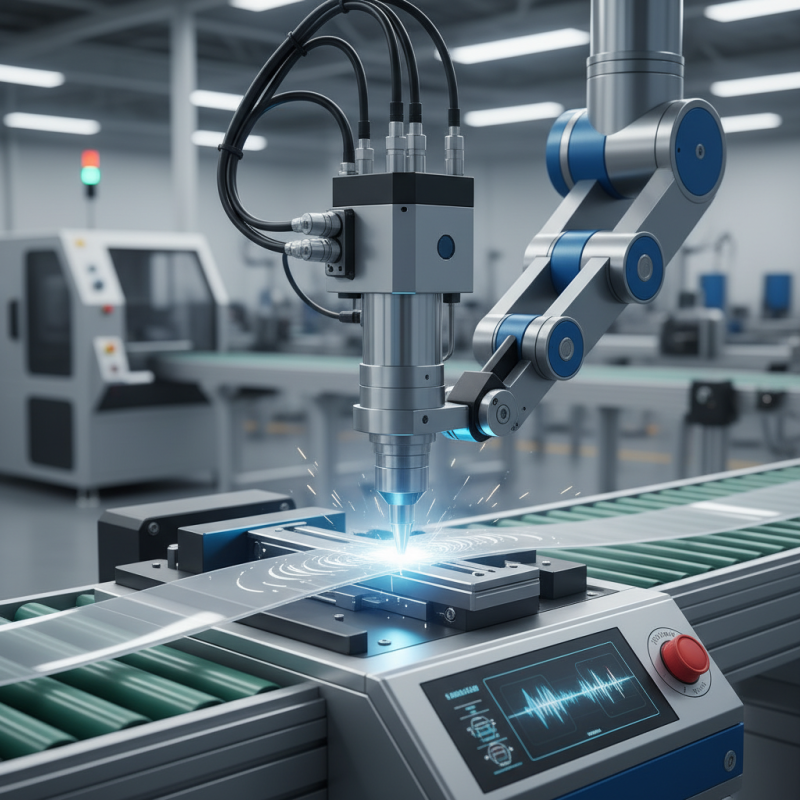

When selecting an ultrasonic spot welder, several key factors should guide your decision. Power output is critical. Many professionals recommend a minimum of 1000 watts for effective welding. This level is necessary for bonding a variety of materials, including plastics and metals. Studies indicate that weld strength often correlates directly with the wattage used. If you're dealing with dense or thicker materials, higher power may reduce the risk of weak joints.

Another factor is frequency, which typically ranges from 20 to 40 kHz in ultrasonic welders. A higher frequency often results in finer control over the welding process. However, it may not always be suitable for all materials. For instance, thicker materials usually require lower frequencies for effective bonding. Experts highlight that versatility in frequency options can be a significant advantage. It allows for adjustments based on the material's properties.

Finally, the design and build quality of the welder play a vital role. Heavy-duty construction ensures longevity and reliability during heavy use. Some models may appear robust but lack the internal quality. Real-world usage shows that welders often face wear and tear, especially in high-demand environments. Regular maintenance checks are essential but may be overlooked. They greatly influence the equipment's performance and lifespan. Be mindful of these details when making your choice; they can significantly impact your welding operations.

In 2026, selecting the right ultrasonic spot welder becomes vital. Many models offer different features. Some focus on precision, while others emphasize speed. Consider the thickness of your materials. This aspect plays a significant role in your choice. Different welders handle various thickness levels. Look for user-friendly controls as well. Ease of operation can save time and reduce errors.

Reputation matters too. Some brands consistently receive high ratings for durability and performance. Yet, exploring lesser-known options can uncover hidden gems. Feedback from users can often reveal critical insights. Pay attention to reviews that mention longevity and maintenance ease. Reliability over time builds confidence in your investment.

Performance is not solely defined by specifications. Sometimes, simpler models outperform high-tech units in real-world applications. Reflecting on your specific needs is essential. What projects will you tackle? How often will you use the welder? These questions guide your decision-making process. Prioritize functionality that aligns with your tasks to maximize your investment.

Ultrasonic spot welding is a precise method of joining materials, mainly used in the manufacturing sector. Safety standards are vital in ensuring operators work in a secure environment. Using ultrasonic equipment can be hazardous if proper protocols are not followed. Operators must use protective gear and ensure that the work area is free from distractions. Regular maintenance of the equipment is essential to prevent malfunctions during operation.

Training is often overlooked but crucial for safety. Workers should understand how the machinery operates and recognize warning signs. In addition to safety gear, equipment should include safety features. These could be automatic shut-off mechanisms and emergency stop buttons. Yet, many users underestimate the importance of regular safety audits. These audits can identify potential risks and enhance workplace safety.

Best practices emphasize the need for clear communication. Workers should report any issues immediately. Often, teams work under tight deadlines and may rush. This rush can lead to mistakes. Understanding the equipment’s limits is also important. Not every situation requires ultrasonic welding; sometimes, alternative methods may be safer. Awareness and adherence to safety standards can significantly reduce risks associated with ultrasonic spot welding.

When considering ultrasonic welders, it’s essential to analyze the cost versus benefits. The initial investment can be substantial. Prices typically range from $5,000 to $50,000. This may seem steep, but the long-term gains can outweigh these costs.

According to industry reports, ultrasonic welding can reduce production time by 30%. Faster processes lead to increased output. More output means higher profitability. Not every business may see these savings instantly. It often depends on how well the machine integrates into existing operations.

Tip: Analyze your current process thoroughly. Identify bottlenecks that ultrasonic welding could address. In some cases, training may be overlooked. Employees need to understand the full capabilities of the machine.

Maintenance is another hidden cost. Regularly scheduled upkeep minimizes downtime. A neglected machine can lead to higher repair expenses. Pay attention to usage patterns. This will help in predicting when maintenance is needed.

Tip: Create a maintenance log to track usage. This will help in budgeting for repairs and replacements, ensuring that your investment is not wasted.

| Model | Power (W) | Price ($) | Weight (kg) | Application | Warranty (Years) |

|---|---|---|---|---|---|

| Model A | 1500 | 1200 | 10 | Plastic Welding | 2 |

| Model B | 2500 | 1700 | 15 | Metal Welding | 3 |

| Model C | 2000 | 1500 | 12 | Fabric Welding | 2 |

| Model D | 3000 | 2000 | 20 | Composite Welding | 5 |