Leave Your Message

Choosing the right Green Ultrasonic Welder can seem daunting. With many options available, decision-making becomes complex. Industry expert Dr. Emily Smith once stated, "A well-chosen welder can greatly enhance efficiency." Her insight underlines the importance of making informed choices.

When considering a Green Ultrasonic Welder, think about specific needs. Different applications require different features. You may need portability or enhanced power. These factors should influence your decision.

Moreover, reflect on the long-term implications. Investing in a quality welder can save costs over time. Yet, it's vital to avoid rushing your choice. A hasty decision might lead to regrets later. Take your time and assess all your options thoroughly.

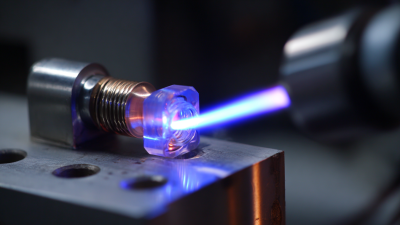

Ultrasonic welding technology offers significant advantages in various manufacturing processes. It uses high-frequency sound waves to join materials, creating strong, permanent bonds. This method is not only efficient but also precise, making it ideal for delicate components. The process avoids excess heat, which is beneficial for heat-sensitive materials. As a result, it minimizes the risk of damage during assembly.

When exploring ultrasonic welding, understanding its benefits is crucial. This technology reduces energy consumption, aligning with eco-friendly practices. It can be cost-effective over time as it reduces waste. However, the initial investment may raise concerns for small businesses. Not all materials weld easily, prompting a need for testing. There’s also the learning curve in operating ultrasonic equipment, which can hinder immediate implementation.

Evaluating different options helps in selecting the best green ultrasonic welder. Look for models that offer adjustable power settings. This feature enhances flexibility across various applications. Keep in mind, though, that the best choice depends on specific production needs. Each business has unique requirements and constraints that must be acknowledged.

| Feature | Description | Benefits |

|---|---|---|

| Power Output | Measured in Watts, determines the efficiency of the welder. | Higher power enables faster welding and better bond strength. |

| Frequency | Typically ranges from 20 kHz to 40 kHz. | Affects the weld quality and suitability for different materials. |

| Type of Control System | Digital or analog systems for setting parameters. | Digital systems allow for precise control and reproducibility. |

| Material Compatibility | Suitable for various plastics, textiles, and metals. | Versatility to handle different applications and industries. |

| Cooling System | Air-cooled vs water-cooled systems. | Efficient cooling extends the life of the welder during high-volume production. |

| Portability | Size and weight of the welder. | Aids in application in various locations and setups. |

| User Interface | Ease of use and accessibility of controls. | A user-friendly interface leads to fewer errors and faster training. |

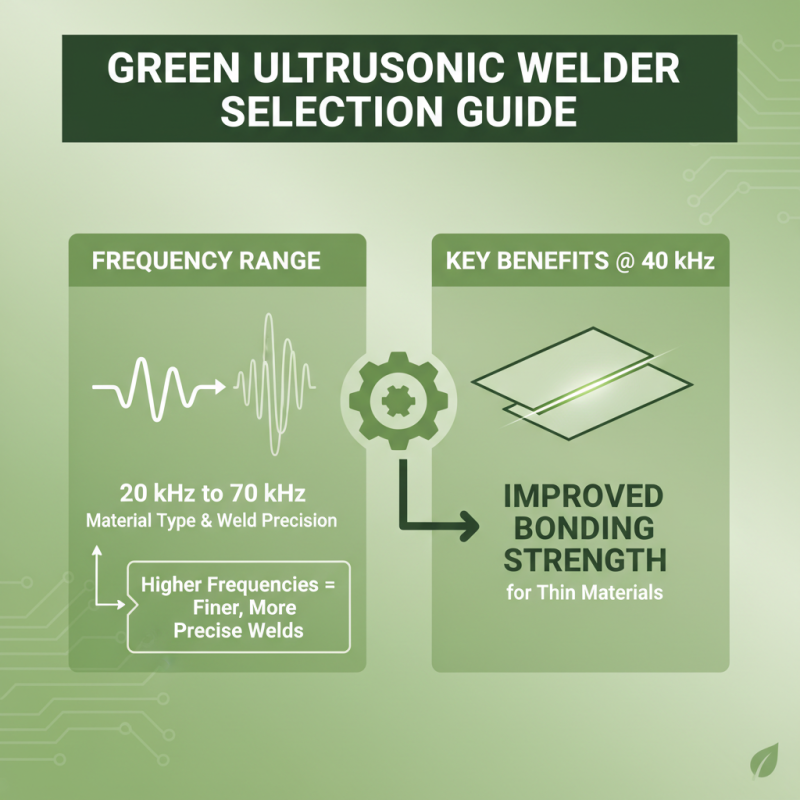

When selecting a green ultrasonic welder, key features play a crucial role in decision-making. First, consider the frequency range. Ultrasonic welders typically operate between 20 kHz and 70 kHz. This range affects the type of materials that can be welded. Higher frequencies yield finer and more precise welds. Notably, reports indicate that welders operating at 40 kHz can significantly improve bonding strength in thin materials.

Another critical feature is the power output. Most units range from 500 watts to 3000 watts. Higher wattage can lead to faster welding and deeper penetration, which is vital for certain applications. However, excessive power can also lead to overheating and material damage. According to industry surveys, about 25% of users reported issues due to mismanaged power settings.

Tips: Always review specific application requirements first. Look into feedback from previous users, as real-world performance often diverges from specifications. Lastly, consider energy efficiency; select models that consume less energy without sacrificing performance. A solid understanding of these features will guide your choice effectively.

When evaluating ultrasonic welders, performance and efficiency are crucial. An effective welder should consistently produce strong, reliable bonds. Inspecting the power output is key. A higher wattage often translates to faster welding speeds. Yet, too much power can lead to material deformation.

Look for machines with adjustable settings. This allows for greater control over the process. Materials vary in thickness and composition. A one-size-fits-all approach may not yield the best results. Efficiency also relates to energy consumption. A welder that uses less power while maintaining quality can significantly reduce costs over time.

Consider user reviews and testimonials. They often reveal insights into real-world performance. A machine may have impressive specifications on paper but falter under actual use. Pay attention to the machine's maintenance requirements as well. Regular upkeep is necessary for consistent performance. Over time, neglect can lead to diminished efficiency. Evaluating these aspects can guide you toward making a more informed decision.

Choosing the right green ultrasonic welder is essential for reducing environmental impact. Consider the materials your projects require. Some materials can be harmful if not handled properly. Look for options made from recyclable or biodegradable substances. This can significantly lessen waste in your production process.

Tips: Always inspect sourcing processes. Are the materials sustainably obtained? Verify that the manufacturer uses green practices in production. This is crucial for ensuring overall sustainability. Moreover, check energy consumption. An efficient welder minimizes energy use, promoting a greener footprint.

Explore the machine's design as well. Compact and lightweight models often consume less energy. They may also offer easy upgrades for better performance. However, not all designs fit every need perfectly. Assess your specific requirements to prevent wasteful spending. If the chosen welder is too advanced or underperforming, it may impact your environmental goals negatively.

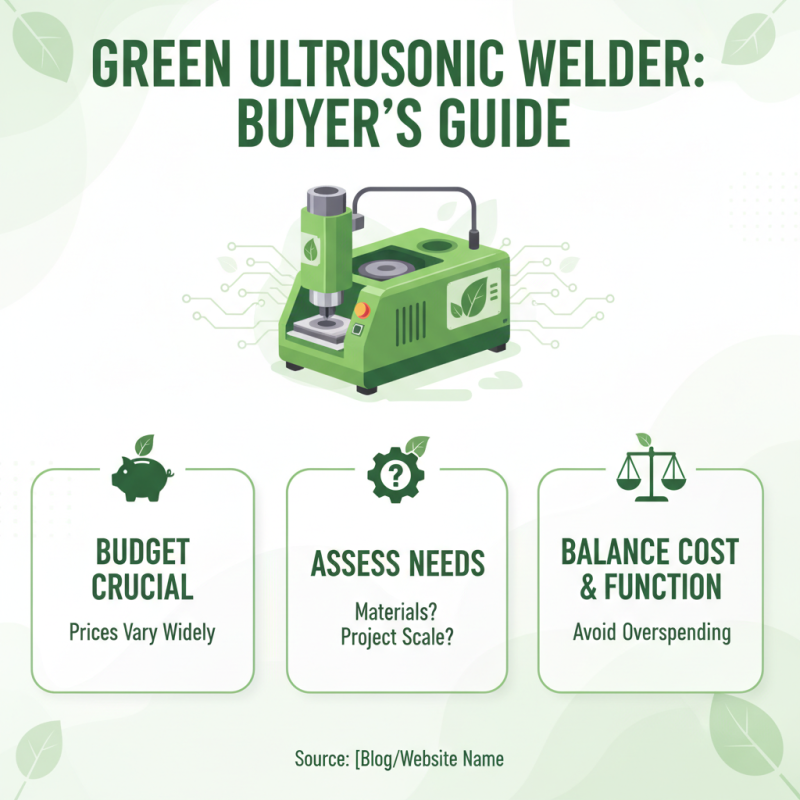

When it comes to purchasing a green ultrasonic welder, budget considerations are crucial. Prices vary widely based on features and capabilities. It's essential to determine your specific needs before making a decision. Think about the materials you'll be working with and the scale of your projects. A high-end model might not be necessary for small tasks. Balancing cost and functionality is key.

Consider the long-term savings related to energy efficiency. A greener welder may have a higher upfront cost but could save money on electricity bills over time. Think about maintenance costs too. Cheaper welders might incur higher repair expenses. Reflect on reliability and durability as well. These factors can influence your overall budget in the long run.

Don't forget to explore alternative options. Sometimes, high-quality used equipment can be more budget-friendly. However, be wary of quality issues that could arise. It's vital to research and compare multiple options. This might require additional time and effort, but it often leads to better purchases. Make sure your investment aligns not just with current needs but also future goals.