Leave Your Message

In the evolving world of textiles, the choice of an Ultrasonic Fabric Welder becomes crucial. Industry expert Dr. Emily Chen highlights this need by stating, “Selecting the right welder can define the quality of your production.” As we approach 2026, several factors influence this decision.

The technology behind Ultrasonic Fabric Welders has advanced significantly. Different models offer various features, and understanding these options can be overwhelming. Factors such as power output, frequency, and ease of use vary widely. Each point merits consideration as it impacts performance.

Choosing the best Ultrasonic Fabric Welder requires careful thought. It's not just about features; it's about how those features fit your specific needs. Buyers often overlook compatibility with materials. Additionally, while price is important, investing in quality can lead to better long-term results.

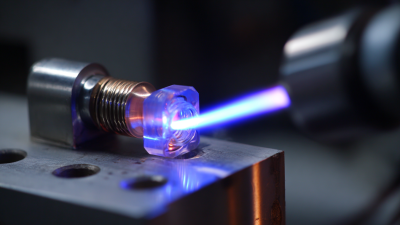

When selecting an ultrasonic fabric welder, several factors come into play. The frequency of the device is crucial. Most fabric welders operate at 20kHz, but some specialized applications might need higher frequencies. Higher frequencies can yield finer welds. However, ensure that the frequency suits your specific fabrics.

Power output is another important consideration. A higher wattage typically allows for faster welding. Yet, too much power can damage delicate materials. Finding the right balance between power and fabric type is essential. Moreover, the design of the welder affects usability. Look for ergonomic features that enhance comfort during operation. Ease of maintenance is also key; a welder that is difficult to maintain can lead to downtime.

Material compatibility is often overlooked. Ensure the welder can handle the variety of fabrics you frequently use. Some machines struggle with thicker or multi-layered materials. The quality of the ultrasonic horn should not be ignored either. A poor-quality horn may result in inconsistent welds. Regular inspection and testing can save you from costly mistakes.

In 2026, there are various types of ultrasonic fabric welders available in the market. Each type serves different purposes and industries. For instance, handheld ultrasonic welders are portable and easy to use. They are perfect for small projects and quick repairs. However, they may lack the power needed for larger tasks. Users might find themselves struggling with efficiency, especially in high-demand environments.

Bench-mounted ultrasonic welders are another common option. These machines are more robust and suitable for continuous operation. They provide better production rates and precision. Yet, some workers may notice that setup takes more time. It requires a stable workstation, which can be a drawback for small businesses. Choosing the right machine means balancing portability and efficiency.

Another category includes automated ultrasonic welders. These are designed for high-volume production. They integrate with larger systems for seamless operations. However, the complexity of automation presents challenges. Training staff to operate such machines can be demanding. Companies must consider the learning curve and its impact on productivity. Each type of ultrasonic fabric welder has its strengths and limitations, making informed choices crucial.

When choosing an ultrasonic fabric welder, the key features matter most. Look for power settings that suit your fabric types. A machine with adjustable frequency can handle different materials better. This ensures clean welds without damaging delicate fabrics.

Tips: Check the power output carefully. Too high can burn the fabric. Too low may result in weak seams.

Stability is crucial. A well-designed ultrasonic welder should have a sturdy frame. This prevents movement during operation, leading to consistent results. Consider a model with easy-to-use control panels. Intuitive controls minimize errors and make learning easier.

Tips: Read user reviews. They can reveal stability issues or control difficulties others have faced. It’s better to learn from their experiences. Reliability is often revealed in the first few uses. If the machine falters, rethinking your choice is wise.

| Feature | Importance | Recommended Specifications |

|---|---|---|

| Power Output | High power ensures efficient and quick welding | 1000W to 5000W |

| Frequency | Higher frequency can lead to finer welds | 15 kHz to 40 kHz |

| Control System | Sophisticated controls enhance precision and consistency | Digital control with touchscreen interface |

| Material Compatibility | Ability to weld various fabric types | Compatible with natural and synthetic fabrics |

| Size and Portability | Compact designs save space and improve mobility | Tabletop or portable design options |

| Cooling System | Efficient cooling prevents overheating during operations | Air or water-cooled systems |

| Warranty and Support | Good warranty and support increase trust | Minimum 1-year warranty with technical support |

When selecting an ultrasonic fabric welder, evaluating the manufacturer’s reputation is crucial. A strong reputation often indicates reliability and quality. Look for manufacturers with years of experience. Check reviews and testimonials from clients. Peer feedback can provide deep insights into product performance.

Customer support is another vital aspect. Effective support can save time and money. Ask potential manufacturers about their support services. Do they offer training? Is technical assistance readily available? These questions are important. A company with responsive support can make a significant difference in your long-term experience.

Consider how well the manufacturer communicates. Clear communication reflects their professionalism. If they are slow to respond, it may raise red flags. Evaluate their willingness to address your concerns. A good manufacturer should show interest in building a relationship, not just making a sale. Remember, a solid partnership can enhance your production efficiency.

When budgeting for an ultrasonic fabric welder, consider the initial costs carefully. These machines can vary greatly in price. A basic model might seem affordable, but remember the hidden expenses. Accessories, maintenance, and supplies can add up quickly. It’s wise to set aside extra funds for these needs.

Think about the long-term investment as well. Cheaper options may lack durability. They could require constant replacement, which costs more over time. Evaluate the features that matter most to your projects. Sometimes, spending a bit more upfront pays off. Look for reliability, efficiency, and versatility.

Research is crucial. Read user reviews. Talk to people in the industry. Some may have had poor experiences with low-cost models. Others might share unexpected costs that arose later. Understanding the true cost of ownership helps make an informed decision. Make sure you are ready for all aspects of the purchase.