Leave Your Message

In the rapidly evolving world of manufacturing, choosing the best Ultrasonic Welder For Sale in 2025 has become a critical task for engineers and production managers alike. With advancements in technology and more stringent production standards, the right ultrasonic welder can significantly impact the efficiency and quality of product assembly. Industry expert Dr. Emily Carter, a leading authority in ultrasonic welding, emphasizes that "the proper selection of equipment is fundamental in achieving optimal welding results that meet today's market demands."

As we move forward into 2025, the market for ultrasonic welders is expected to expand, offering a plethora of options for buyers. However, with more choices comes the challenge of identifying which features and specifications matter most. Key factors such as frequency, power output, and the materials being welded should be carefully considered to ensure that the selected Ultrasonic Welder For Sale aligns with the specific needs of a production line.

Navigating through the myriad of potential options can be daunting, but by focusing on critical aspects such as technology advancements, cost-effectiveness, and manufacturer support, businesses can make informed decisions that will lead to successful outcomes. Ultimately, the quest for the ideal ultrasonic welder should be viewed as an investment, laying the groundwork for enhanced productivity and innovation in manufacturing processes.

When selecting an ultrasonic welder in 2025, there are several factors that should be taken into account to ensure alignment with your manufacturing needs. First and foremost, the frequency of operation is a critical consideration. Ultrasonic welders operate at various frequencies, typically ranging from 20 kHz to 70 kHz, impacting the types of materials that can be welded effectively. For instance, whereas lower frequencies tend to be more suitable for thicker materials, higher frequencies allow for finer applications like delicate assemblies. According to recent industry reports, the demand for high-frequency ultrasonic welding is projected to increase by approximately 15% per annum, driven largely by advancements in the electronics and medical device sectors.

Another essential factor is the power output of the ultrasonic welder. The power rating, generally expressed in watts, determines the efficiency and speed of the welding process. A welder with adjustable power settings can offer versatility across different projects, allowing manufacturers to tailor their processes to achieve optimal results. Industry analyses indicate that ultrasonic welders with variable power settings have seen a rise in popularity, with a reported 27% increase in product adoption among manufacturers looking for flexibility in operations. Additionally, features such as automated controls and monitoring systems can greatly enhance productivity and weld consistency, which are critical for maintaining quality in modern manufacturing environments.

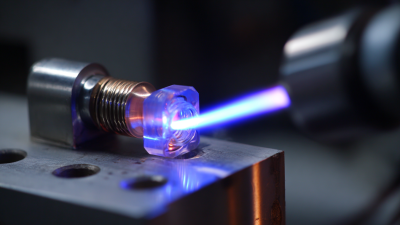

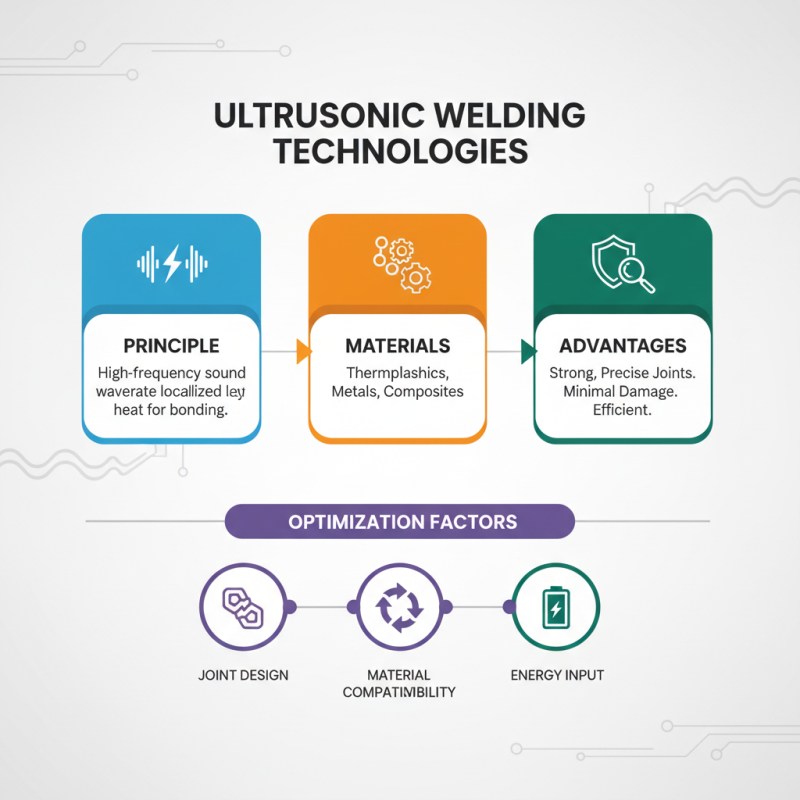

Ultrasonic welding technologies have rapidly advanced, offering a variety of solutions tailored to different industries and applications. One major technique involves the use of high-frequency sound waves to create a bond between materials, which can be particularly effective for thermoplastics, metals, and composites. The efficiency of these technologies lies in their ability to generate localized heat, minimizing damage to surrounding areas and resulting in strong, precise joints. Depending on the application, factors such as joint design, material compatibility, and energy input must be carefully considered to optimize the welding process.

Comparative analysis of different ultrasonic welding systems reveals that various designs cater to specific demands. For instance, handheld ultrasonic welders are ideal for small-scale operations or fieldwork, allowing for mobility and versatility. In contrast, automated ultrasonic systems are better suited for high-volume production environments, providing consistency and speed. Additionally, integrating advanced features like digital controls and real-time monitoring can enhance process precision and reduce downtime. Ultimately, selecting the right technology requires an understanding of the specific application requirements, material types, and production goals to ensure efficient and reliable welding solutions.

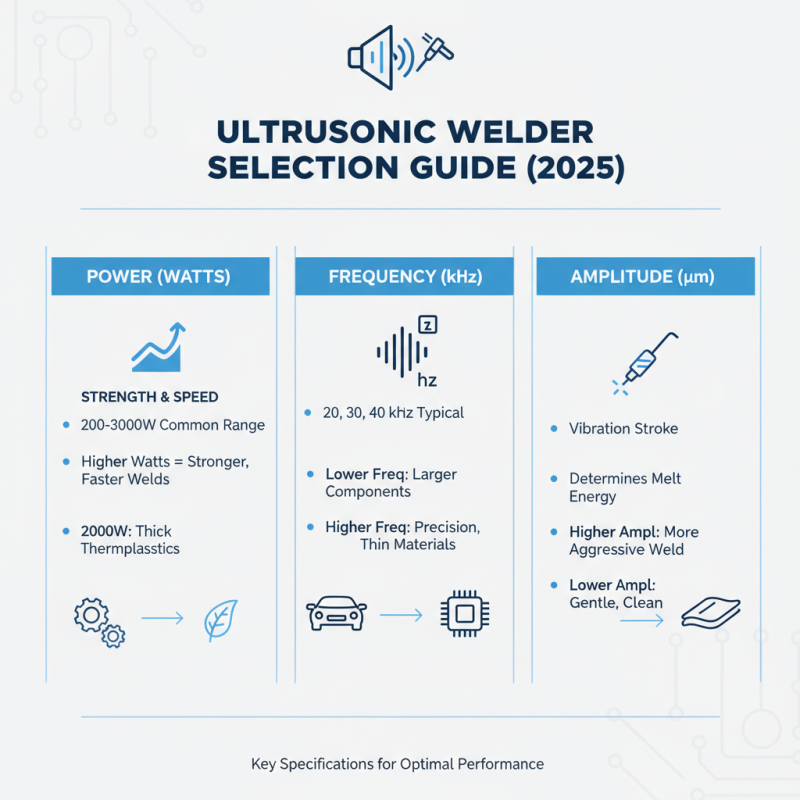

When selecting the best ultrasonic welder for sale in 2025, understanding its specifications—power, frequency, and amplitude—is crucial. Power output, typically measured in watts, plays a significant role in the welder's efficiency and capability. According to industry reports, welders with power ratings between 200 to 3000 watts are common in manufacturing, with higher wattage indicating greater welding strength and speed. For instance, a power output of 2000 watts is often ideal for applications involving thicker thermoplastics, while lower wattage may suffice for delicate materials.

Frequency is another critical specification, impacting the welder's performance for different applications. Ultrasonic welders generally operate within a frequency range of 20 kHz to 40 kHz. A frequency of 20 kHz is usually preferred for welding larger components and thicker materials, as it generates more robust energy transfer. Conversely, higher frequencies, such as 40 kHz, are suitable for more precise applications, including thin films and intricate components. Research indicates that adjusting the frequency according to material requirements can enhance joint quality and reduce cycle times.

Amplitude, which indicates the maximum displacement of the ultrasonic wave, is also vital in achieving effective welding results. Typical amplitudes range from 10 to 100 microns, with higher amplitudes resulting in stronger bonding at the interface of the materials. Industry analysis reveals that optimizing amplitude settings significantly affects weld integrity and consistency, making it essential to choose a welder that allows for precise adjustments based on specific application needs. Therefore, evaluating these specifications will guide you in choosing an ultrasonic welder tailored to your production requirements and material types.

The rise of automation in ultrasonic welding equipment marks a significant shift in the manufacturing landscape, enhancing productivity and precision across various industries. Recent reports indicate that the global ultrasonic welding equipment market is projected to grow at a CAGR of 7.5% from 2023 to 2029, driven largely by the increased adoption of automation technologies. This integration not only streamlines processes but also reduces operational costs, allowing manufacturers to maintain competitiveness in a rapidly evolving market.

Automation facilitates real-time monitoring and data analytics, which are crucial for optimizing welding parameters and ensuring consistent quality. Studies show that automated ultrasonic welders can achieve up to a 30% improvement in weld strength compared to manual systems. Furthermore, with advancements in artificial intelligence and machine learning, these automated systems are becoming smarter, learning from each weld to enhance future performance. The growing emphasis on sustainability and efficiency is prompting industries to embrace these technologies, as they provide not only better results but also align with eco-friendly initiatives.

As automation continues to shape the ultrasonic welding sector, manufacturers must consider these advancements when selecting their welding equipment. High efficiency, reduced downtime, and improved quality assurance are just a few benefits that underline the importance of harnessing advanced automation in ultrasonic welding operations. With demand for automated solutions on the rise, investing in the latest ultrasonic welders is poised to be a game-changer for industry players aiming to thrive in the competitive market of 2025 and beyond.

The decision to invest in ultrasonic welding technology in manufacturing has grown substantially due to its cost-effectiveness and efficiency. A detailed cost-benefit analysis reveals that ultrasonic welding can reduce production times by up to 50% compared to traditional welding methods. According to a report from the International Welding Institute, manufacturers that integrate ultrasonic welding can see a decrease in energy consumption by approximately 30%, which contributes significantly to lower overhead costs. Additionally, eliminating the need for consumables, such as adhesives and other bonding agents, can lead to considerable savings over time.

Moreover, the initial investment in ultrasonic welding equipment often pays off within a year through improved output and reduced labor costs. The Global Ultrasonic Welding Machine Market Report forecasts an annual growth rate of approximately 8.5%, driven by industries ranging from automotive to electronics, all capitalizing on the durability and precision that ultrasonic welding provides. With reduced waste generation and enhanced product quality, the benefit realized by manufacturers utilizing this technology is not just financial but also contributes to sustainable practices that are increasingly important in the current manufacturing environment.

| Parameter | Ultrasonic Welder Model A | Ultrasonic Welder Model B | Ultrasonic Welder Model C |

|---|---|---|---|

| Price (USD) | $15,000 | $18,500 | $20,000 |

| Power Output (W) | 2000 W | 2500 W | 3000 W |

| Frequency (kHz) | 20 kHz | 30 kHz | 40 kHz |

| Weight (kg) | 150 kg | 160 kg | 175 kg |

| Warranty (Years) | 3 Years | 2 Years | 5 Years |

| Energy Efficiency (%) | 85% | 90% | 92% |

| Output Quality Rating (out of 5) | 4.2 | 4.5 | 4.7 |