Leave Your Message

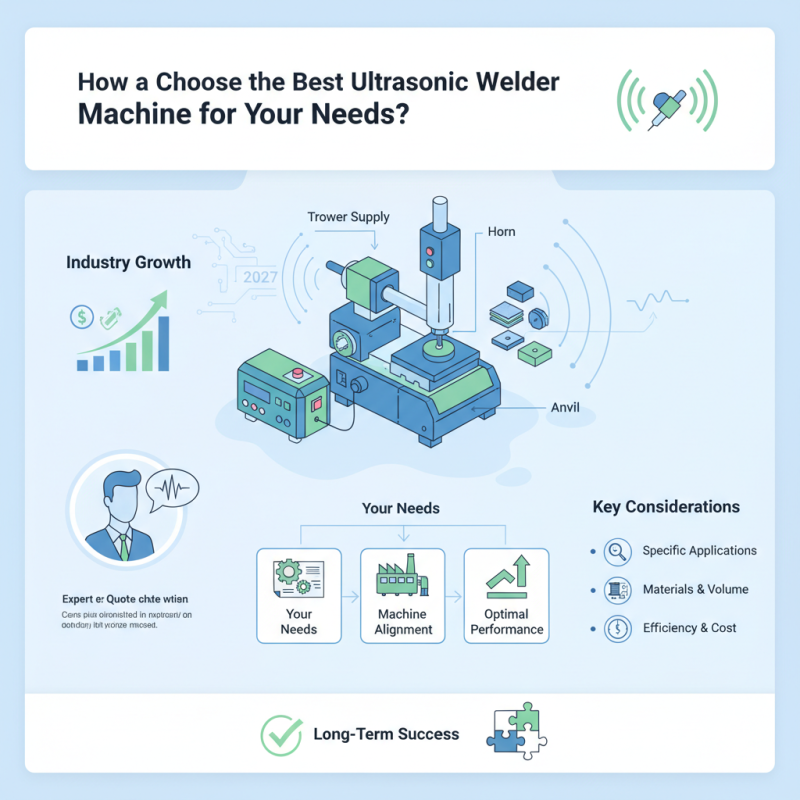

Choosing the right Ultrasonic Welder Machine can drastically affect production quality. In recent years, the ultrasonic welding industry has grown significantly. A report by Market Research Future states that the market is projected to reach USD 800 million by 2027. This growth highlights the increasing importance of choosing effective machinery.

Industry expert Dr. James Collins emphasizes, "Investing in quality equipment is vital for optimal performance." His insight underscores the necessity of understanding individual needs. The right machine should align with specific applications, materials, and production volumes to avoid costly mistakes. It's essential to consider whatever shortcomings a machine may have against production requirements.

Moreover, many users overlook machine features that may seem trivial but greatly impact efficiency. The wrong choice could lead to delays or increased costs. It’s a reflection point for manufacturers to assess what truly matters in their welding processes. Understanding these elements is crucial for long-term success in utilizing an Ultrasonic Welder Machine.

Ultrasonic welding is a fascinating technology that joins materials using high-frequency sound waves. The process generates heat at the interface of two surfaces, causing them to bond together. This method is highly effective for plastics and thin metals. Understanding the fundamentals can guide your choice of equipment.

The key to successful ultrasonic welding is the frequency of the sound waves. Common frequencies range from 20 kHz to 40 kHz. Higher frequencies provide finer welding but may not be suitable for thicker materials. Selecting the right frequency is crucial. Testing various parameters can be tedious but necessary. Sometimes, the initial setup might not deliver desired results. Experimentation is part of the learning curve.

Consider the materials you plan to weld. Different combinations require different approaches. For instance, some plastics may need specific energy levels. If you push too hard, you might damage the components. User error can lead to imperfect welds. Trial and error can be frustrating, but it often leads to valuable insights. Adjustments will help refine your process over time.

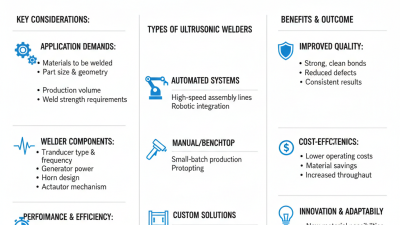

When selecting an ultrasonic welder, identifying your specific application needs is crucial. Different industries require distinct welding techniques. For example, medical device production often demands high precision. In contrast, automotive components may need stronger welds due to harsher environments. Analyze the materials you plan to bond. Are they thin films or robust plastics? This will affect your choice.

Consider the scalability of the machine as well. A unit that fits your current needs may not support future projects. Think about the volume of production as well. High output might overwhelm a small welder. Also, weigh the training required for your team. Some machines are user-friendly; others may confuse operators.

Finally, don't forget about maintenance and support. An advanced machine may require expert care. Ensure you have access to spare parts. Investing in the wrong machine can lead to costly downtimes. Reflect on these factors carefully. Making a hasty decision could impact your productivity significantly.

Choosing the right ultrasonic welder machine involves careful consideration of its key features and specifications. One crucial factor to evaluate is the frequency range. Most ultrasonic welders operate between 20 kHz and 40 kHz. A lower frequency offers more power but may compromise precision. Higher frequencies provide finer control but less energy. Understanding your application's needs will guide you in selecting the appropriate frequency.

Another significant specification is the power output. This is typically measured in watts. Machines with higher wattage can handle more challenging materials. However, they may also generate excessive heat, which can be problematic. Balance is essential here; too much heat can lead to material damage.

**Tips:** When evaluating machines, consider extra features like adjustable power settings and digital controls. These can enhance the user experience. It’s also beneficial to look at the machine's versatility. Can it work with different materials? This flexibility can save you time and money.

Also, look for customer feedback. Sometimes user experiences reveal problems not apparent in technical specs. Pay attention to concerns about reliability and maintenance. These insights can inform your decision-making process.

| Feature | Description | Importance |

|---|---|---|

| Frequency | Common frequencies include 20 kHz, 30 kHz, and 40 kHz which influence welding speed and results. | High |

| Power Output | Measured in watts, typically ranging from 100W to 3000W, affecting the performance and materials that can be welded. | High |

| Control System | Digital vs. analog controls, impacting user interface and precision. | Medium |

| Welding Time | Duration of the welding process, which influences production efficiency. | High |

| Size and Portability | Overall machine footprint and weight, affecting workspace and mobility. | Medium |

| Material Compatibility | Types of materials (plastics, metals) that the welder can effectively join. | High |

| Cost | Initial investment versus long-term savings from efficiency and durability. | High |

When selecting an ultrasonic welder, it's crucial to compare different brands and models in the market. Each brand presents distinct features. Some prioritize speed, while others focus on precision. Check specifications carefully. Look for machines with adjustable power settings. This capability can significantly enhance versatility.

User feedback is essential. Reviews often highlight common issues. Some machines may not deliver consistent results. Users frequently mention difficulties in setup or maintenance. Consider these factors when comparing models. A welder could look great on paper but may fall short in real-world applications.

Don’t rush your decision. It’s tempting to choose the most popular model. However, think about your specific needs. A highly rated machine may not be the best for your project type. Reflect on what you really require. Size, weight, and warranty should all be considered. Make a list of priorities before committing.

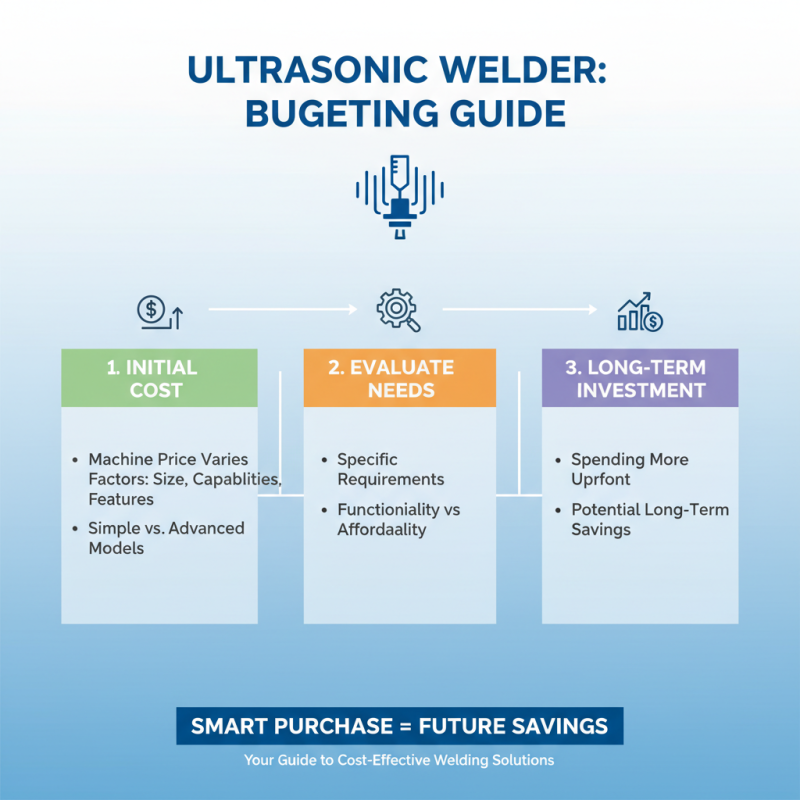

When purchasing an ultrasonic welder, budgeting is crucial. First, understand the initial cost of the machine. Prices vary significantly. Factors such as size, capabilities, and features influence the price. A simpler model may be affordable, but lack advanced functionalities. Evaluate your specific needs. Sometimes spending more upfront can save costs in the long run. Always consider long-term investments.

In addition to the initial purchase, think about the ongoing costs. Maintenance and parts can add up. If repairs are frequent, this might indicate the need for a better quality machine. Energy consumption is another factor often overlooked. A machine that consumes less power can save money over time.

Also, don't forget about training costs. If your team isn’t experienced, training is essential. This could impact your overall budget significantly. Review all these elements before making a decision. A well-planned budget helps avoid unexpected expenses down the line. Keep reassessing your priorities to ensure the best fit for your operations.