Leave Your Message

When selecting the ideal ultrasonic welder for your industrial applications, numerous factors must be considered to ensure optimal performance and efficiency. The effectiveness of ultrasonic welding heavily relies on the components used, particularly the transducers ultrasonic welder, which are crucial in converting electrical energy into mechanical vibrations. These vibrations generate the necessary heat to bond materials seamlessly, making them indispensable in the welding process.

In today's competitive landscape, industries ranging from automotive to medical are increasingly adopting ultrasonic welding technology due to its precision and speed. Therefore, understanding the different types of ultrasonic welders available in the market, as well as their specific capabilities, can significantly impact production quality and overall cost-effectiveness. By exploring key features, specifications, and the benefits of advanced transducers ultrasonic welder systems, businesses can make well-informed decisions tailored to their unique operational needs.

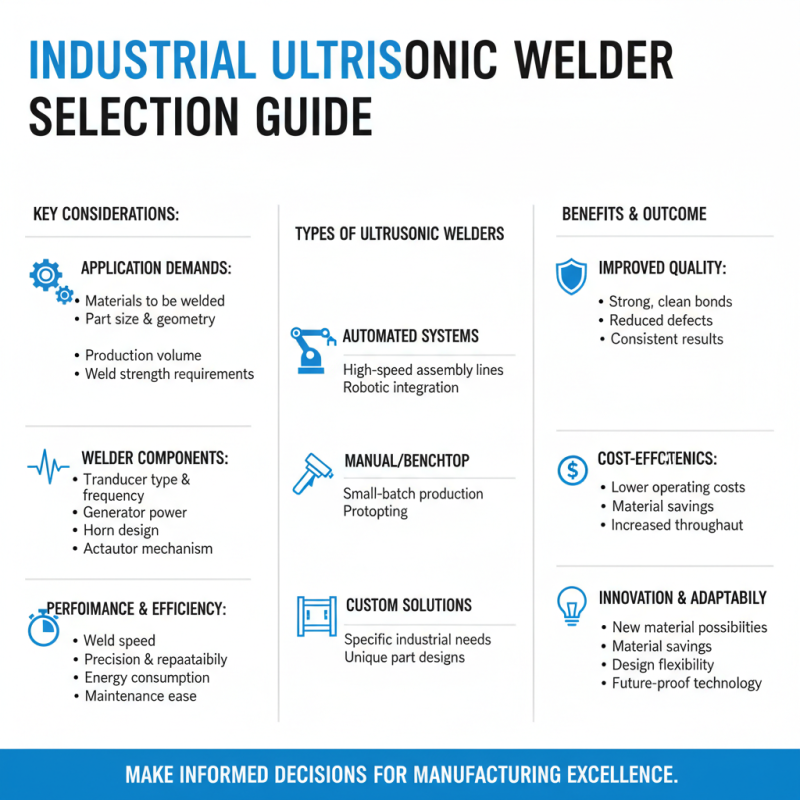

Choosing the best ultrasonic welder goes beyond mere specifications; it involves a strategic assessment of the application demands and the desired outcome. In this guide, we will delve into the essential criteria for evaluating ultrasonic welders, thereby equipping you with the knowledge necessary to enhance your manufacturing processes.

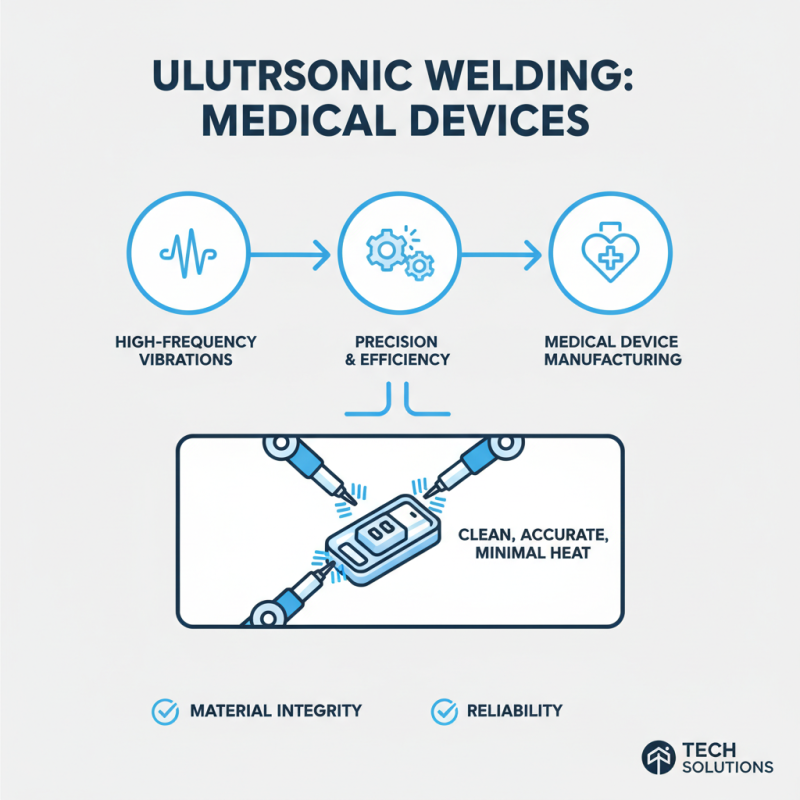

Ultrasonic welding technology is transforming various industrial applications, driven by its capacity for precision and efficiency. This method utilizes high-frequency ultrasonic vibrations to create bonds between materials, making it particularly advantageous in sectors like medical device manufacturing. The medical industry demands stringent cleanliness and accuracy requirements, which ultrasonic welding fulfills by ensuring minimal thermal impact and maintaining material integrity. As a result, this technology is increasingly adopted for assembling devices that require high precision and reliability.

In addition to medical applications, the global ultrasonic welding market is projected to see substantial growth, with an expected market size of USD 1,156 million by 2034, reflecting a robust CAGR of 5.1%. The rise of new energy technologies and the increasing trend toward sustainability in manufacturing processes further fuel this growth. Innovations in ultrasonic welding are also paving the way for advancements in sectors such as aerospace, where lightweight and strong material joints are crucial for enhanced fuel efficiency. This highlights the pivotal role ultrasonic welding plays in meeting modern industrial demands across various applications.

When selecting the best ultrasonic welders for your industrial needs, several key factors must be considered to ensure optimal performance and efficiency. One of the foremost considerations is the specific application for which the welder will be used. Different materials and thicknesses require distinct settings and capabilities from ultrasonic welders. According to industry forecasts, the global solid welding wires market is projected to grow from $5.17 billion in 2025 to $6.88 billion by 2032, highlighting the expanding demand for robust welding solutions.

Additionally, the technological features of the ultrasonic welder are crucial. Look for models that offer advanced controls and customization options to adapt to various welding tasks. The welding training sector is also evolving, with digital and virtual technologies being integrated into training processes. This shift enhances skill development and safety in welding practices, ensuring that operators are well-equipped to utilize ultrasonic welders effectively.

**Tips:**

- Evaluate the welder's power output and ultrasonic frequency to match the materials you'll work with.

- Consider the availability of training resources and support to help operators master the technology.

- Check for compatibility with additional features, such as automation or integration with existing systems, to streamline your operations.

When selecting the best ultrasonic welder for your industrial applications, understanding the specifications related to power, frequency, and amplitude is crucial. Power, usually measured in watts, directly influences the weld's strength and speed. A report by the International Ultrasonics Research Society indicates that welders operating between 500 to 4000 watts can efficiently handle a variety of materials, including thermoplastics and some metals. Higher power levels allow for faster processing times, which can significantly enhance production rates in high-demand environments.

Frequency, typically measured in kilohertz (kHz), affects the ability of the ultrasonic welder to penetrate and melt specific materials. Most ultrasonic welders operate within a range of 20 kHz to 40 kHz. An industry study published in the Journal of Materials Processing Technology highlights that lower frequencies (20 kHz) are better suited for heavier materials, while higher frequencies (up to 40 kHz) are more effective for finer applications, such as delicate electronic components and films.

Amplitude, representing the extent of vibration in the ultrasonic waves, is another key factor. Welders generally operate at amplitudes between 10 to 30 micrometers, with specific requirements depending on the material being welded. Data from the Society of Plastics Engineers shows that an increase in amplitude can enhance bonding strength, particularly in challenging materials or nonwovens, hence playing a significant role in achieving optimal welding results. Understanding these specifications not only assists in making informed decisions but also ensures the selection of equipment that meets specific production needs.

This chart compares the power, frequency, and amplitude of various ultrasonic welders suitable for industrial needs.

When evaluating ultrasonic welders for your industrial needs, cost-effectiveness and return on investment (ROI) are critical factors to consider. The initial purchase price of ultrasonic welders can vary significantly based on their capabilities and features. However, it’s essential to look beyond the upfront costs and analyze the long-term savings generated by these machines. For instance, ultrasonic welding typically requires less energy and produces minimal waste compared to traditional welding methods, resulting in lower operational costs over time.

To further assess ROI, businesses should consider the productivity gains associated with ultrasonic welders. These machines often provide faster welding cycles, allowing for increased output without compromising quality. Additionally, the precision of ultrasonic welders can reduce the likelihood of defects, minimizing rework and material waste. Companies should calculate the potential increases in production and the associated cost savings, comparing them against the total investment.

By thoroughly evaluating both cost-effectiveness and potential ROI, organizations can make informed decisions that align with their operational goals and budget constraints.

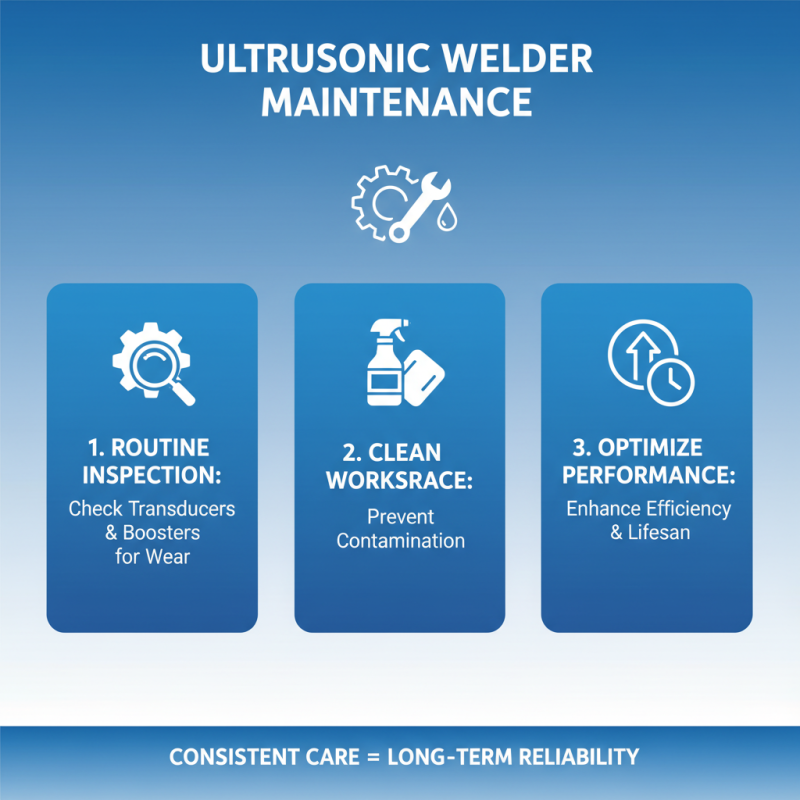

When it comes to maintaining ultrasonic welders for long-term performance, routine checks and meticulous care can greatly enhance their efficiency and lifespan. Regularly inspect the ultrasonic components for wear and tear, ensuring that transducers and boosters are functioning optimally. A clean workspace can prevent contamination that could impair the welding process.

**Tip:** Schedule routine maintenance every six months, focusing on cleaning the horn and ensuring that all electrical connections are secure. This proactive approach helps to identify potential issues before they escalate into costly repairs.

Upgrading ultrasonic welders can also significantly improve their performance. Investing in advanced technology, such as digital controls or modern piezoelectric transducers, can enhance precision in welding applications. Furthermore, keeping software up to date ensures that you’re utilizing the latest features and benefits provided by the manufacturer.

**Tip:** Always consult with your equipment supplier regarding potential upgrades that can maximize your specific welding needs without compromising existing workflows. Regular upgrades can lead to improved productivity and reduced operational costs in the long run.