Leave Your Message

Ultrasonic Soldering and Welding is transforming modern manufacturing. Experts like Dr. Jane Thompson highlight its benefits. She states, "This technology enhances precision and reduces defects." The process uses high-frequency sound waves. This method significantly improves the quality of soldered joints. It also provides a cleaner, faster alternative to traditional techniques.

In today's competitive landscapes, efficiency is essential. Ultrasonic Soldering and Welding not only speeds up production but also minimizes material waste. Many companies are adopting this innovative approach. However, it requires specific training and expertise. Some teams struggle to master the technology. It's vital to invest in proper education and resources.

While the advantages are clear, challenges remain. The initial setup costs can be daunting for small manufacturers. There might be hesitations regarding long-term reliability. Gaining experience with Ultrasonic Soldering and Welding takes time. Despite these hurdles, the potential rewards are significant. Companies must weigh their options carefully before deciding.

Ultrasonic soldering and welding offer unique benefits for modern projects. One significant advantage is the ability to create strong, reliable joints without the need for additional materials. This process uses high-frequency vibrations, reducing the risk of damaging sensitive components. Products can be joined quickly, enhancing production efficiency.

In many industries, the precision required is vital. Ultrasonic welding fits that need perfectly, especially in electronics and medical devices. The ability to control parameters like time and pressure helps ensure consistent quality. However, implementing this technology requires careful planning and adjustment. Misalignment can lead to inadequate bonds. Regular calibration of equipment is essential to maintain optimal performance.

**Tip:** Before starting, test the ultrasonic settings on a small scale. This helps identify the best parameters for your specific materials. It can save time and resources in the long run. Additionally, always consider the environmental impact of your chosen methods. Sustainable practices, though sometimes challenging, are increasingly vital.

Ultrasonic technology is revolutionizing soldering processes. It employs high-frequency sound waves to join materials. These sound waves create rapid vibrations. This results in localized heating, melting the solder without damaging surrounding components. Research shows that ultrasonic soldering can increase joint strength by 40% compared to traditional methods. This technology is particularly beneficial for delicate electronic assemblies.

In practical applications, the precision of ultrasonic welding offers several advantages. For instance, it reduces oxidation and contamination risks. This improves the reliability of connections. However, this process requires careful setup. Misalignment can lead to weak joints. Users must ensure that components are positioned accurately before welding.

Tips: Always calibrate equipment before use. Regular maintenance of ultrasonic transducers is essential. Inspect joints post-soldering to ensure quality. Proper training is vital for operators working with ultrasonic technology. They should understand the physics behind the process. Awareness can help avoid common pitfalls. Keep records of production parameters to identify trends and improve processes over time.

Ultrasonic soldering and welding offer several advantages over traditional methods. One significant difference is the energy efficiency. Ultrasonic techniques often require less energy and time. The precise application of ultrasonic waves can create strong joints quickly. This aspect is crucial for industries aiming to decrease production time. However, achieving the perfect balance requires experimentation.

In contrast, traditional soldering relies on heat to create bonds. This method can lead to overheating sensitive components. The risk of thermal damage is higher, which complicates the process. Moreover, traditional techniques may require more flux, making cleanup more tedious. The skill level of the operator can also impact the quality. Mistakes in traditional measures can lead to weak joints and waste.

One potential drawback of ultrasonic soldering is the initial investment in equipment. It might be costly for smaller projects. Operators may need training to master this technique. Misalignment during the ultrasonic process can result in weak joints too. It is a reminder to continuously evaluate methods for improvement.

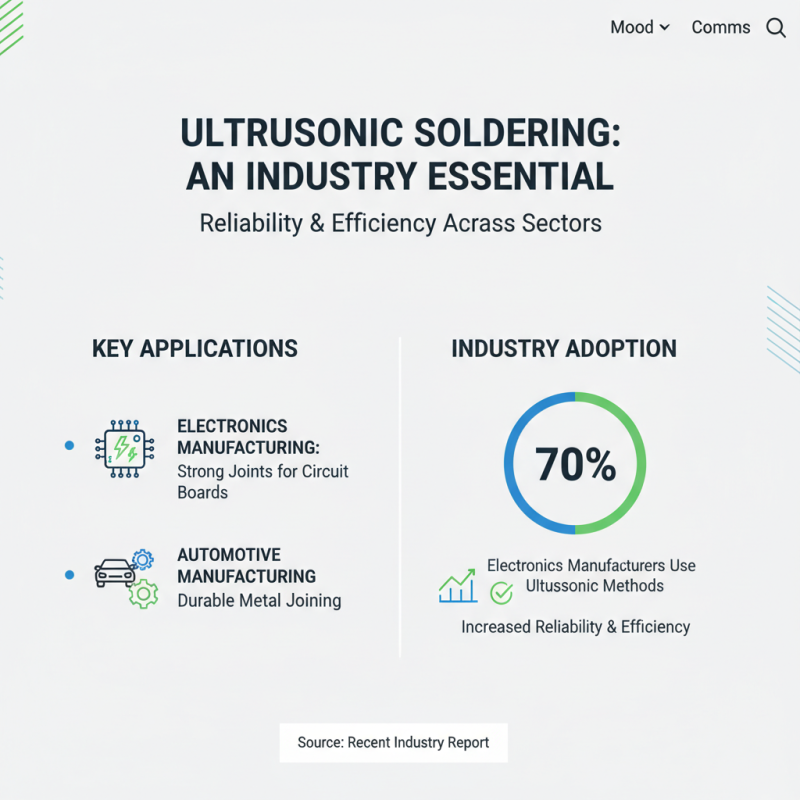

Ultrasonic soldering has become essential in several industries. Its applications range from electronics to automotive manufacturing. In electronics, ultrasonic soldering is used to create strong joints for circuit boards. A recent report highlighted that nearly 70% of electronics manufacturers have adopted ultrasonic methods due to their reliability and efficiency.

Medical device manufacturing is another significant area. Here, ultrasonic soldering ensures precise connections in small devices. The accuracy of these soldering methods reduces the risk of failure. According to industry analysis, 55% of medical device companies prefer ultrasonic soldering for its low thermal impact. This is vital when dealing with heat-sensitive components.

However, some challenges remain. Ultrasonic soldering requires careful calibration. Inadequate settings can lead to weak joints or damage. Additionally, not all materials are compatible with this method. Continuous research is essential to overcome these limitations. The future of ultrasonic soldering hinges on addressing these issues while expanding its reach across various sectors.

When choosing ultrasonic soldering for your projects, several factors come into play. The type of materials you're working with is crucial. Ultrasonic soldering is effective for delicate components. However, it may not be suitable for thicker materials. Consider the heat sensitivity of your parts. Some components can warp under excessive heat. Ultrasonic soldering produces minimal heat, which is a significant benefit.

Another factor is the precision required for your application. Ultrasonic soldering allows for very localized heating. This precision ensures a strong bond while protecting surrounding areas. But, you must evaluate if you have the right equipment and expertise. Not all projects fit this method.

Cost is an important consideration too. Ultrasonic soldering equipment can be an investment. Assess the long-term benefits against your budget. Sometimes, traditional soldering methods might be more viable for budget constraints. Reflect on the specific needs of your project. Balancing these factors can lead to better outcomes.