Leave Your Message

Choosing the right Waterproof Ultrasonic Transducer can be challenging. With the market expanding, options abound. An industry report by TechInsights predicts a 12% growth in ultrasonic device applications over the next five years. This highlights the increasing demand for reliable waterproof solutions.

Expert Dr. Sarah Moore, a leading voice in the ultrasonic technology field, states, "Selecting the right transducer is crucial for efficiency and longevity." Her insights reflect the complexities faced by users today. Each application requires specific features, making the decision process daunting.

Waterproof Ultrasonic Transducers serve various sectors, from medical devices to industrial cleaning. However, the available choices can confuse even seasoned professionals. With many factors to consider, such as frequency and size, users often overlook critical details. Balancing performance and environmental resistance is not straightforward. It's essential to reflect on your unique needs amid market noise.

Ultrasonic transducers convert electrical energy into sound waves. They play a crucial role in various applications. Understanding how they work is essential for making an informed choice.

These devices consist of a piezoelectric element. When voltage is applied, it vibrates and generates sound waves. Waterproof ultrasonic transducers are designed to operate in wet conditions. This feature is vital for applications like underwater sonar and industrial cleaning.

Tips: Look for transducers with IP ratings. An IP68 rating indicates they can withstand submersion. Consider the frequency as well; higher frequencies provide better resolution. However, they may have limited range.

Selecting a transducer isn't just about specifications. Think about the environment it will be in. Harsh conditions can affect performance. You might need to test different models. Trial and error can help find the right fit. Always consider durability and maintenance needs when making your decision.

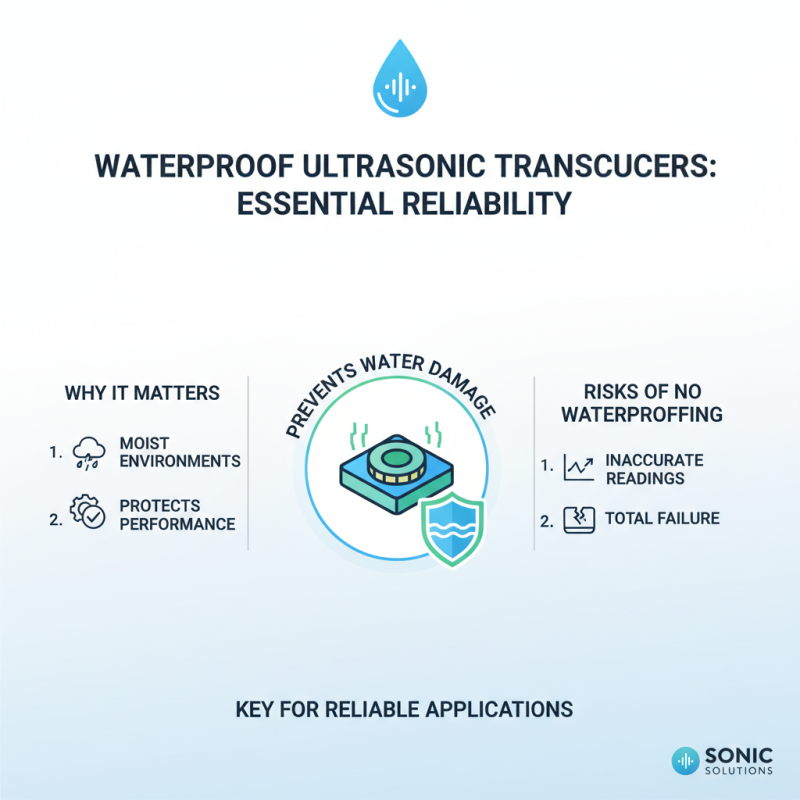

Waterproof features in ultrasonic transducers are crucial for various applications. Many environments expose these devices to moisture, where water can compromise their performance. For instance, if a transducer gets wet, it can lead to inaccurate readings or even total failure. Therefore, selecting a transducer with robust waterproof characteristics is essential for reliability.

When choosing a waterproof ultrasonic transducer, consider the IP rating. This rating indicates how well the device can resist water and dust. Higher ratings signify better protection. Think about where the device will be used. Harsh conditions like marine environments demand higher standards. It's easy to overlook these details in the design phase, but they matter in the long run.

The materials used in making the transducer also play a vital role. Some materials can corrode over time. Others can withstand exposure to different chemicals. Manufacturers often provide specifications, but understanding these can be challenging. A knowledgeable supplier can help clarify these aspects. It’s important to ensure the chosen transducer meets both functional and environmental requirements to avoid potential pitfalls down the road.

Choosing a waterproof ultrasonic transducer is essential for effective performance in various environments. There are several factors to consider. The depth rating is crucial. Will it be submerged in water? Different applications require different depth capabilities. Checking the transducer's material can also make a significant difference. Some materials resist corrosion better than others.

Another important factor is frequency. Higher frequencies provide better resolution but may have limited range. Lower frequencies can penetrate deeper but offer less detail. Understanding your application's specific needs will help identify the right balance. It can be easy to overlook these details, leading to potential issues down the line. Sometimes, users choose based solely on price rather than specifications.

Compatibility with existing systems is another aspect to consider. Ensure it will integrate smoothly without added modifications. Keep in mind that installation complexity can affect performance. Testing the transducer's reliability in real-world conditions can reveal unexpected challenges. Reflecting on these factors can help make a more informed decision.

When selecting a waterproof ultrasonic transducer, understanding the different types can be pivotal. There are several categories, each designed for specific applications. Some transducers are built for industrial uses, while others may suit medical or consumer electronics. Knowing the intended application helps narrow choices.

Ceramic transducers are popular for their sensitivity and frequency range. They perform well in water and can detect minute changes. However, they may require careful handling to avoid damage during installation. On the other hand, piezoelectric transducers can be robust but might lack some sensitivity. Their versatility makes them common in many sectors.

It's essential to consider the environment in which the transducer will operate. Harsh conditions can affect performance. Think about depth, temperature, and possible contaminants. Take time to weigh these factors. A wrong choice could lead to installation troubles or premature failure. Constructing a clear checklist might help here. Remember, each type has strengths and weaknesses deserving your attention.

Waterproof ultrasonic technology is gaining traction across various industries. Its applications stretch from marine exploration to healthcare. Many underwater devices rely on these transducers to perform critical tasks. This technology helps in detecting changes in materials, measuring distances, and even monitoring aquatic life.

In agriculture, waterproof ultrasonic sensors are used for soil moisture monitoring. They provide real-time data, helping farmers optimize water usage. Similarly, in food processing, these sensors ensure cleanliness in manufacturing. They help detect defects in packaging and enhance product safety.

Tips: When choosing a waterproof ultrasonic transducer, consider the operating environment. Assess factors like temperature, pressure, and exposure to contaminants. Also, ensure that the frequency suits your specific application needs. Maintain clarity in your design to avoid future complications. Choosing the wrong specs might lead to performance issues. Always revisit your requirements and be open to adjustments as technology evolves.