Leave Your Message

When embarking on a new project, selection of the right welding technology can significantly influence both efficiency and product quality. According to recent industry reports, the global ultrasonic welding market is projected to reach $2.9 billion by 2027, driven by its applications in automotive, electronics, and medical sectors. Ultrasonic welding technology offers unique advantages, such as reduced production time and enhanced joint integrity, making it a favorable choice for manufacturers looking to optimize processes. For those seeking flexibility and cost-effectiveness, hiring an "Ultrasonic Welder For Hire" can provide instant access to top-tier equipment and expertise without the burdensome investment in capital machinery. This blog will delve into seven compelling reasons to consider hiring an ultrasonic welder for your next project, aiding you in making informed decisions to elevate your production capabilities.

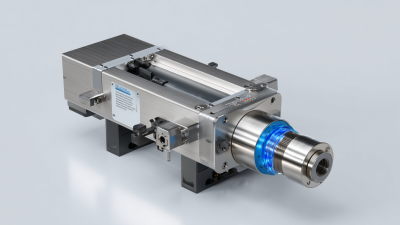

Ultrasonic welding has emerged as a game-changer in various industries, particularly due to its unparalleled precision and meticulous quality control. Unlike traditional welding methods, ultrasonic welding employs high-frequency sound waves to create a bond between materials, ensuring minimal heat generation and a lower risk of damaging sensitive components. This technology is especially beneficial when working with delicate materials, such as plastics and thin films, where precision is paramount to achieving reliable connections without compromising the integrity of the materials involved.

One of the standout advantages of ultrasonic welding is its ability to produce consistent and repeatable results. As the process is highly controlled, manufacturers can ensure that each weld meets stringent quality standards, reducing the likelihood of defects and enhancing overall product reliability. Moreover, the instantaneous nature of ultrasonic welding speeds up production times, allowing for quicker project turnaround without sacrificing quality. This combination of precision and efficiency makes ultrasonic welding an ideal choice for projects requiring refined craftsmanship and dependable performance, positioning it as a key player in modern manufacturing landscapes.

This chart illustrates the various benefits of using ultrasonic welding in projects, rated on a scale of 1 to 10. Enhanced precision and quality control are highlighted as the most significant advantages, making it a compelling choice for future projects.

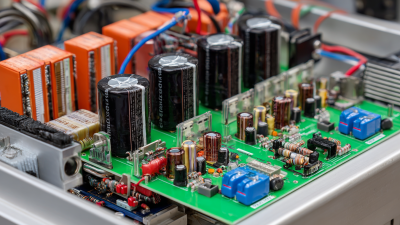

When executing short-term projects, cost-effectiveness is often a primary concern. Hiring ultrasonic welders can significantly reduce overall expenses compared to purchasing and maintaining expensive welding equipment.

According to a report by the International Institute of Welding, companies that opt for hiring specialized welding equipment can save up to 30% in operational costs. This is particularly pertinent in industries like automotive and medical devices, where precision and reliability are paramount, yet projects may not justify a long-term investment in equipment.

When it comes to maximizing productivity in manufacturing, ultrasonic welding technology shines as a leading choice. With the ability to achieve rapid production times, businesses can significantly reduce lead times for their projects. According to a report by Grand View Research, the global ultrasonic welding market is projected to reach USD 2.83 billion by 2025, highlighting the growing reliance on this efficient technology. The speed of ultrasonic welding comes from its unique capability to join materials without the need for supplementary adhesives or fasteners, allowing for a seamless welding process that takes mere seconds.

Moreover, ultrasonic welding not only accelerates production but also enhances precision. A study from the International Journal of Adhesion and Adhesives notes that ultrasonic welding achieves strong and consistent bond quality, which is crucial in industries such as automotive and electronics, where the integrity of connections can significantly impact product performance. This combination of quick turnaround and reliability makes ultrasonic welding a compelling option for businesses looking to stay competitive in a fast-paced market. Embracing such advanced technology can make a tangible difference in both the efficiency and quality of production outputs.

| Reason | Description | Time Saved | Applications |

|---|---|---|---|

| High Speed | Ultrasonic welding significantly reduces the welding process time. | Up to 90% faster than traditional methods. | Automotive, Aerospace |

| Minimal Setup | Quick setup and changeovers between different tasks. | 20% time reduction in setup. | Consumer Goods, Electronics |

| Energy Efficient | Lower energy consumption compared to traditional welding. | 30% less energy needed. | Medical Devices, Packaging |

| High Consistency | Ensures uniform welds with minimal human error. | Reduction in defects by 50%. | Textiles, Electrical Components |

| Versatility | Can weld a variety of materials and shapes. | Flexible production timelines. | Multi-material Assemblies |

| Less Waste | Produces less scrap material during the welding process. | Waste reduction by 40%. | Sustainable Manufacturing |

| Reduced Post-processing | Minimizes the need for additional finishing processes. | Cuts finishing time by 25%. | Aerospace, Automotive Parts |

Ultrasonic welders have gained prominence across various industries due to their versatility in bonding diverse materials. From plastics to metals and textiles, these machines can efficiently weld components that cater to multiple applications. This flexibility makes them an ideal choice for manufacturers looking to tackle different projects without needing multiple welding techniques. For instance, in the automotive sector, ultrasonic welding is used to assemble interior components and battery packs, showcasing its adaptability to the unique needs of each project.

When considering ultrasonic welders for hire, it’s essential to assess the range of materials your project entails. Keep in mind that different materials may require specific settings for optimal bonding. A helpful tip is to consult with the welder rental company to understand their equipment’s capabilities and limitations regarding the materials you plan to use.

Moreover, don't overlook the importance of project timelines. Given the efficiency of ultrasonic welding, opting for this technology can significantly reduce production times. Just remember to communicate your deadlines clearly when hiring the welder to ensure that the equipment is available and optimized for your schedule.

Ultrasonic welding has emerged as a formidable technology in manufacturing, especially when it comes to sustainability. By harnessing high-frequency ultrasonic vibrations, this process can achieve strong bonds between materials while significantly minimizing waste. According to a report by the International Journal of Advanced Manufacturing Technology, traditional welding methods account for an average of 25% material waste due to excess heat and the use of additional joining materials. In contrast, ultrasonic welding ensures precise energy delivery, resulting in less excess material and more efficient use of resources.

Moreover, energy consumption is markedly lower with ultrasonic welding compared to conventional methods. The American Welding Society reports that ultrasonic welding consumes up to 50% less energy during operation. This reduction not only lowers production costs but also lessens the environmental impact of manufacturing processes. Companies that integrate ultrasonic welding into their operations contribute to sustainable practices, aiming to achieve compliance with stricter environmental regulations while enhancing their corporate social responsibility profiles. As industries continue to prioritize eco-friendly solutions, the advantages of ultrasonic welding cannot be overstated, making it a viable choice for modern manufacturing projects focused on sustainability.