Leave Your Message

In today's fast-paced manufacturing landscape, the demand for efficient and reliable joining processes has surged, making the ultrasonic welder a vital tool for various industries. Renowned ultrasonic welding expert, Dr. Emily Stanton, emphasized the technology's benefits, stating, "Ultrasonic welding not only enhances production speed but also ensures a clean and precise join, which is essential in maintaining product quality." As companies look to streamline their operations, finding an "Ultrasonic Welder For Sale" becomes increasingly important.

Purchasing an ultrasonic welder can significantly improve manufacturing efficiency, reduce material waste, and lower production costs. With advancements in ultrasonic technology, businesses can leverage these machines to create strong, durable bonds without the need for additional adhesives or fasteners. The growing availability of ultrasonic welders on the market presents an opportunity for manufacturers to invest in cutting-edge technology that will support their production needs for years to come, thereby enhancing overall competitiveness in their respective industries.

In conclusion, as the ultrasonics welding market continues to evolve, potential buyers should consider the long-term benefits associated with investing in an "Ultrasonic Welder For Sale." By doing so, they can not only enhance operational efficiency but also ensure superior product integrity, setting themselves apart in a competitive manufacturing environment.

Ultrasonic welding technology has revolutionized modern manufacturing by providing efficient and reliable joining solutions across various industries. This innovative process utilizes high-frequency ultrasonic vibrations to achieve molecular bonding between thermoplastics and certain metals. According to a report by ResearchAndMarkets, the global ultrasonic welding market is expected to grow significantly, with a projected CAGR of 6.5% from 2021 to 2026. This growth highlights the increasing adoption of ultrasonic welding in sectors such as automotive, electronics, and medical devices due to its ability to offer precise and consistent welds.

One of the key benefits of ultrasonic welding is its speed compared to traditional welding methods. The entire welding cycle can be completed in fractions of a second, drastically reducing production time and increasing throughput. Additionally, ultrasonic welding does not require additional materials such as adhesives or fillers, leading to cost savings in manufacturing processes. Moreover, the process generates minimal heat, which reduces the likelihood of thermal damage to sensitive components, making it ideal for applications in electronics and medical device assembly, where integrity and precision are paramount. With such advantages, it's clear why manufacturers are increasingly considering ultrasonic welders as a vital investment for their production lines.

When considering the purchase of an ultrasonic welder, it's crucial to identify the key features that will best meet your specific needs. One of the primary aspects to look for is the machine’s power output. A welder with adjustable power settings allows for better control over the welding process, making it suitable for various materials and applications. This flexibility not only enhances the quality of the weld but also helps in achieving precise finishes, which are essential in industries like medical device manufacturing and automotive parts assembly.

Another important feature is the frequency range of the ultrasonic welder. Higher frequency machines tend to promote better bonding in thin materials, while lower frequencies are suited for thicker workpieces. Additionally, consider the usability of the welder; models equipped with user-friendly interfaces and programmable features can significantly streamline the operational process. This is especially beneficial in a production environment, as it reduces the learning curve for new operators and enhances workflow efficiency. Thus, focusing on these key features will ensure that you invest in an ultrasonic welder that aligns with your production requirements and quality standards.

| Feature | Description | Importance |

|---|---|---|

| Frequency Range | Defines the operating frequency of the welder, typically between 20 kHz and 70 kHz. | Critical for the type of materials you can weld. |

| Power Rating | Measured in watts, indicates the energy output of the ultrasonic welder. | Affects the welding speed and effectiveness on various materials. |

| Control System | Refers to the interface and technology for adjusting settings. | Essential for precision and ease of operation. |

| Ultrasonic Transducer | Component that converts electrical energy into ultrasonic vibrations. | Key to the welder's performance and durability. |

| Tooling Options | Various attachments available for different welding applications. | Enables versatility in production processes. |

| Machine Size and Portability | Dimensions and weight of the ultrasonic welder. | Important for workspace considerations and mobility. |

Ultrasonic welders are increasingly becoming an essential tool in various industries due to their ability to create strong, durable joints without the need for additional adhesives or fasteners. In the automotive sector, for instance, ultrasonic welding is extensively used for assembling plastics, which helps reduce weight and improve fuel efficiency. The precision and speed of this method also lead to enhanced production rates, making it ideal for high-demand manufacturing environments such as automotive assembly lines.

In the medical industry, ultrasonic welders play a crucial role in the production of medical devices and packaging. Their ability to join dissimilar materials, such as plastics used for blood bags or the components of surgical instruments, ensures the integrity and sterility of medical products. Additionally, in the electronics industry, ultrasonic welding facilitates the reliable connection of delicate components in smartphones and other devices, contributing to their longevity and performance. The versatility of ultrasonic welders across these sectors highlights their significance in modern manufacturing processes, further driving the demand for these innovative machines.

Investing in an ultrasonic welder can significantly boost efficiency and product quality in various manufacturing sectors, particularly in plastics and metals. According to a report by the International Ultrasonic Association, ultrasonic welding systems can improve production throughput by up to 30% compared to traditional welding methods. As businesses seek to streamline operations, the initial investment in a high-quality ultrasonic welder can pay off quickly through increased productivity and reduced labor costs.

When considering the costs associated with purchasing an ultrasonic welder, it is essential to evaluate both the immediate and long-term benefits. While the upfront cost might seem high—often ranging from a few thousand to tens of thousands of dollars—business owners must account for the long-term savings. Reports indicate that companies using ultrasonic welding experience a decrease in material waste by up to 50% and a reduction in energy consumption, as these welders often require less power compared to conventional welding processes.

Tips: When evaluating the right ultrasonic welder for your business, consider not only the cost and specifications but also the potential savings in materials and cycle times. Additionally, take into account the potential for scalability; an investment in a versatile ultrasonic welder can position your business to expand production as demand increases. Engaging with suppliers for demo units can also provide valuable insights into the machine's operational efficiency and suitability for your specific applications.

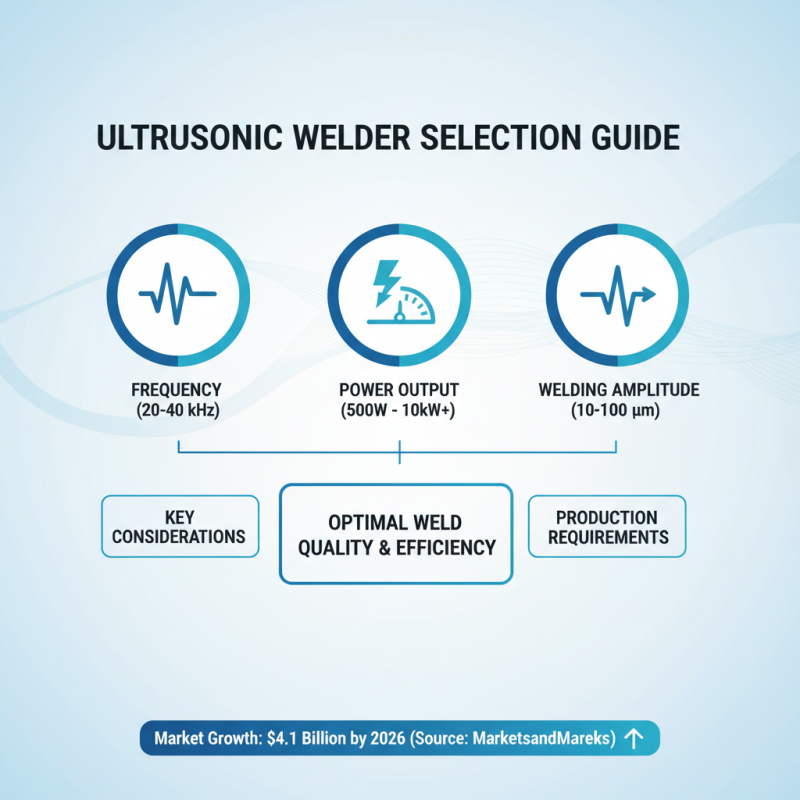

When considering an ultrasonic welder for your operations, it is crucial to focus on specific features that meet your production requirements. According to a recent market analysis by MarketsandMarkets, the ultrasonic welding equipment market is expected to reach $4.1 billion by 2026, indicating a growing trend in the adoption of these systems across various sectors. Therefore, it is essential to evaluate factors such as frequency, power output, and welding amplitude, as these will significantly affect the quality and efficiency of your welding processes.

Another vital aspect to consider is the type of materials you intend to work with. A study published by the International Journal of Advanced Manufacturing Technology emphasizes that the effectiveness of ultrasonic welding varies with material density and thickness. Selecting a welder compatible with your specific materials—be it plastics, metals, or composites—can enhance productivity and minimize scrap rates. Additionally, assess the machine's versatility; models that blend different frequencies can better accommodate a wider range of applications, thereby ensuring you can adapt to evolving project demands.