Leave Your Message

In today's fast-paced manufacturing landscape, the choice of machinery can significantly impact efficiency. The "Ultrasonic Welder Handheld" is a noteworthy tool. It streamlines the welding process in various projects. Industry expert Dr. Emily Cartwright once said, “The Ultrasonic Welder Handheld transforms tedious tasks into fast, reliable solutions.” This tool is designed for versatility.

Imagine working on intricate designs without the hassle of traditional welding methods. The Ultrasonic Welder Handheld allows for precision and flexibility. It is ideal for small parts, providing a neat and clean weld. Yet, not everyone recognizes its full potential. Some may overlook its advantages, relying on outdated techniques. Others may underestimate the learning curve involved in using it effectively.

The power of the Ultrasonic Welder Handheld lies in its capability to bond materials quickly. Users can achieve strong joints without investing in complicated machinery. However, it's essential to understand the limitations and proper techniques. There can be mistakes in settings, leading to poor results. Adopting this technology requires commitment, but the rewards can be substantial. Embracing this tool could redefine project outcomes for many professionals.

Handheld ultrasonic welders are versatile tools widely used in various industries. They operate by employing high-frequency sound waves to create heat, which fuses materials together. This process is efficient and precise, making it ideal for intricate projects. Recent industry studies reveal that ultrasonic welding can reduce energy consumption by nearly 30%. This efficiency appeals to manufacturers looking to lower costs.

The functionality of these devices is straightforward. They consist of a transducer that converts electrical energy into mechanical vibrations. These vibrations are then focused on the material surfaces that need joining. A report from the International Institute of Welding highlights that over 60% of automated assembly processes now utilize ultrasonic welding technology. This statistic showcases the growing preference for this method in producing durable and high-quality joints.

Despite their advantages, handheld ultrasonic welders have limitations. They may not be suitable for thicker materials, which can restrict their application range. Operators must be trained to optimize the settings for different tasks. Some projects might require adjustments that can lead to trial and error. This learning curve can be frustrating, but it also encourages innovation in techniques and applications. Understanding these nuances is crucial for successful project execution.

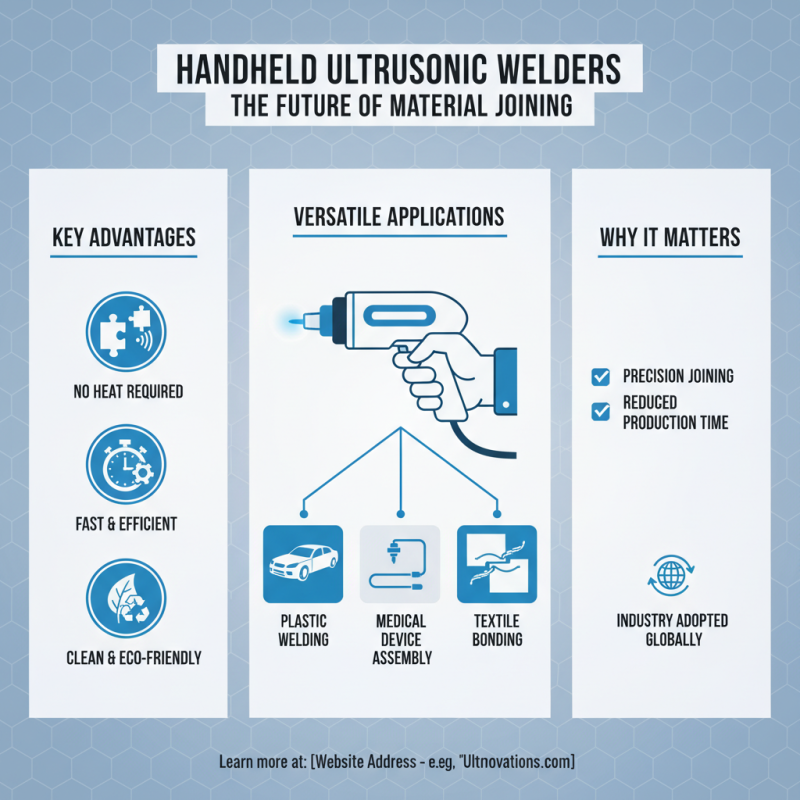

This chart illustrates various features of handheld ultrasonic welders, highlighting their significance in different project categories.

Handheld ultrasonic welders offer remarkable advantages for various projects. They provide clean and quick joining solutions, reducing the need for adhesives or mechanical fasteners. According to a recent industry report, ultrasonic welding can achieve bond strengths exceeding 90% of the materials' original strength. This level of efficiency is appealing for manufacturers seeking speed and quality.

The compact design of handheld ultrasonic welders enhances versatility in multiple applications. Their portability allows operators to work in tight spaces, which is often challenging for larger machinery. Statistics indicate that using handheld devices can increase production speed by 30%. However, some users note that mastering the technique requires practice and careful calibration. Adjustments to settings can impact the integrity of the weld and ultimately influence project outcomes.

Another key benefit is the reduction of waste. Unlike traditional welding methods, ultrasonic welding generates minimal excess material. Reports show that waste is reduced by up to 50% when using this technology. While these advantages are compelling, users must remain vigilant about potential operator errors. Every project requires attentive monitoring to ensure optimal results. Understanding the variables at play, including material compatibility and ambient conditions, is crucial for success.

Handheld ultrasonic welders have gained immense popularity in various industries. They are effective in joining materials without traditional heat sources. This approach offers distinct advantages, especially in plastic welding, medical device assembly, and textile industries.

In the automotive sector, handheld ultrasonic welders are increasingly used. Reports indicate that ultrasonic welding provides strong and durable joints, reducing assembly time by up to 40%. It's particularly useful for joining different plastic materials. The aerospace industry also benefits, as these welders reduce the weight of components while ensuring robust connections.

Tips: When choosing a handheld ultrasonic welder, consider the weight. It's essential for prolonged use. Moreover, ensure the machine you select can handle the types of materials you work with.

In the packaging industry, these welders are invaluable. They ensure leak-proof seals that meet strict regulatory standards. However, adequately training staff is often overlooked. Sometimes, improper use can lead to miscued welds. This not only affects product integrity but can also lead to waste.

Tips: Regularly review training protocols. Consider investing time in hands-on workshops. Proper training maximizes the machine's efficiency and ensures consistent results.

When selecting a handheld ultrasonic welder, consider its frequency range. Different materials require specific frequencies for effective welding. A lower frequency may work well for thicker materials. Meanwhile, higher frequencies are ideal for finer fabrics or films. Assess the sonic capability to ensure it matches your project needs.

Portability is another vital factor. A lightweight design allows for easier handling during lengthy tasks. Look for a comfortable grip, as this can reduce fatigue. Battery life is critical too. A welder that needs frequent recharging can disrupt work.

Lastly, examine the accessory options. Some models provide various tips and sonotrodes for different applications. Having these tools can enhance your flexibility in projects. Be cautious, though; too many attachments can complicate your workflow. Choosing the right ultrasonic welder is about balancing features, usability, and practical requirements.

Handheld ultrasonic welders stand out compared to traditional welding methods. They use high-frequency sound waves to create strong, durable bonds. This technology minimizes heat exposure, reducing the risk of warping. In contrast, traditional welding often generates excessive heat. This can damage sensitive materials or require additional finishing work.

The versatility of handheld ultrasonic welders is impressive. They can work on various materials like plastics and metals. Traditional welding may demand specific tools for different materials. This can complicate projects and increase costs. However, the ultrasonic process requires skill to master. It might not always yield perfect results on the first attempt. Operators must practice to achieve consistent quality.

Ease of use is another key factor. Handheld welders are generally lighter and more portable. This makes them suitable for remote job sites. Traditional welding setups often need bulky equipment. Still, there may be limitations with the handheld models in thicker materials. Each method has its advantages and imperfections, requiring careful consideration.