Leave Your Message

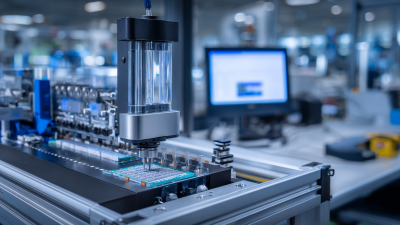

In the rapidly evolving world of manufacturing, the choice of equipment can significantly impact production efficiency and product quality. Among the essential tools in modern fabrication is the Ultrasonic Welder Machine, recognized for its ability to join materials quickly and effectively, particularly in industries such as automotive, electronics, and medical device manufacturing. As businesses increasingly seek to streamline processes and improve their product offerings, understanding how to select the best ultrasonic welder becomes imperative.

This guide aims to illuminate the critical factors involved in choosing the best Ultrasonic Welder Machine tailored to your specific manufacturing needs. Whether you are a seasoned professional or a newcomer to the industry, making an informed decision about the right equipment can enhance your production capabilities and ensure consistent quality. By analyzing different types of ultrasonic welders and their applications, we will provide valuable insights into making a selection that aligns with your operational goals while considering aspects like power output, frequency, and ease of use. Ultimately, the right ultrasonic welder can not only boost efficiency but also contribute significantly to long-term success in your manufacturing endeavors.

Ultrasonic welding is a cutting-edge technology that utilizes high-frequency ultrasonic vibrations to create a strong bond between materials, predominantly plastics and metals. This process involves placing the materials to be joined in contact with each other and applying ultrasonic energy, which generates localized heat at the interface. The result is a rapid melting of the material surfaces, leading to a solid-state weld without the need for additional adhesives or fasteners. This technology is particularly beneficial in applications where precision and speed are crucial, such as in the automotive, aerospace, and electronics industries.

The versatility of ultrasonic welding extends to a wide range of applications, from joining delicate components like medical devices to bonding intricate parts in consumer electronics. It offers numerous advantages, including reduced energy consumption, shorter cycle times, and the ability to weld dissimilar materials. Moreover, the process ensures minimal thermal impact on the surrounding areas, preserving the integrity of sensitive components. As industries continue to seek efficient and reliable methods for assembling complex products, understanding the nuances of ultrasonic welding technology will be essential for making informed decisions about the best ultrasonic welder machines tailored to specific manufacturing needs.

| Feature | Description | Recommended Usage |

|---|---|---|

| Power Output | Measures the energy supplied to the welding process, typically in watts. | High power output for thicker materials; lower output for thinner materials. |

| Frequency | Typically ranges between 20 kHz to 40 kHz, affecting the precision of the weld. | High frequency for small components; lower for larger parts. |

| Type of Control | Manual, semi-automatic, and fully automatic control options available. | Choose based on operational workflow and skill level of personnel. |

| Welding Area Size | The dimensions of the area where the welding occurs, influencing the size of parts that can be welded. | Select based on product dimensions to be welded. |

| Material Compatibility | The types of materials that can be welded using ultrasonic technology, such as plastics and metals. | Ensure compatibility with the materials used in your manufacturing process. |

| Cost | The initial investment needed for the machine, as well as ongoing maintenance costs. | Evaluate total cost of ownership against your budget and production needs. |

When selecting an ultrasonic welder for your manufacturing needs, several key factors must be considered to ensure optimal performance and efficiency. First and foremost, understanding the power output of the machine is crucial. According to a report by the International Ultrasonic Welding Association, machines with a power output ranging from 500 to 2000 watts are ideal for most applications, as they provide the necessary energy for effective bonding without compromising the quality of the materials being welded. This range is particularly important for industries that require precision in joining delicate components.

Another critical factor is the frequency of the ultrasonic welder. Generally, machines with frequencies between 20 kHz and 40 kHz are most commonly used, as noted in a recent study published in the Journal of Manufacturing Processes. The choice of frequency impacts the type of materials that can be welded, with higher frequencies being suitable for thinner materials while lower frequencies work better with thicker substrates. Additionally, considering the machine's build quality and the manufacturer's reputation in the market can significantly affect the longevity and reliability of the equipment, ultimately leading to reduced downtime and maintenance costs. Implementing these considerations will enable manufacturers to select the best ultrasonic welder tailored to their specific production requirements.

When selecting the best ultrasonic welder for your manufacturing needs, it’s essential to consider the various types available and their specific applications. Ultrasonic welders can be categorized based on their design and functionality, including hand-held welders, automated systems, and modular setups. A report from the Ultrasonic Technology Market Analysis indicates that automated ultrasonic welding systems are witnessing a growth rate of over 8% annually, emphasizing their efficiency and adaptability in high-volume production environments.

Hand-held ultrasonic welders are ideal for small-scale operations or manual tasks, offering portability and ease of use. In contrast, automated ultrasonic systems are designed for precision and can seamlessly integrate into existing manufacturing lines. According to a study published by the International Journal of Advanced Manufacturing Technology, automated systems provide significant reductions in cycle time and increase operational efficiency by over 30%, making them suitable for industries such as automotive and electronics where speed and consistency are critical.

Modular ultrasonic welders offer flexibility as they can be configured to handle different materials and welding depths. This adaptability is crucial in a market driven by the need for customization. As reported by TechNavio, the demand for modular ultrasonic welding solutions is expected to rise, particularly in sectors focusing on intricate and delicate components. Understanding the specific demands of your manufacturing process will enable you to choose the ultrasonic welder that aligns with your production goals and enhances overall productivity.

This chart compares different types of ultrasonic welders based on their power output and frequency range, helping manufacturers choose the best option for their needs.

When selecting the best ultrasonic welder machine for your manufacturing needs, assessing the machine specifications and features is crucial for ensuring optimal performance. Key specifications to consider include the frequency of operation, power output, and the amplitude of vibration. Higher frequency machines, typically around 20 kHz to 40 kHz, are suitable for precise welding tasks and can handle smaller components. However, if your work involves thicker materials, lower frequencies could provide enhanced penetration and strength.

In addition to these technical specifications, consider the features that contribute to usability and flexibility. Look for machines that offer programmable settings, enabling operators to adjust parameters according to specific welding tasks. Features like automatic shut-off, monitoring systems, and ergonomic design can facilitate seamless integration into existing manufacturing lines. Furthermore, ensure the machine is built with robust materials that can withstand intensive use, reducing downtime and maintenance costs. By carefully evaluating these aspects, you can choose an ultrasonic welder that not only meets your immediate needs but also adapts to future innovations in manufacturing technology.

When considering the purchase of an ultrasonic welder machine, budgeting and cost considerations are paramount. A comprehensive approach involves evaluating not only the initial purchase price but also the long-term operational costs, maintenance expenses, and potential return on investment (ROI). Industry reports indicate that ultrasonic welding technology can reduce production costs by up to 40% when compared to traditional welding methods, creating a strong financial incentive for manufacturers to adopt this technology.

Moreover, it is crucial to take into account the ongoing costs associated with ultrasonic welders. This includes expenses related to specialized tooling and periodic maintenance, which may average around 10-15% of the machine’s initial cost annually. Manufacturers should also consider the cost of training personnel to operate these machines efficiently. By investing in quality ultrasonic welders, businesses can expect improvements in productivity and product quality, which can significantly offset initial costs. Investing the time to assess and allocate a proper budget for these machines can lead to substantial benefits in overall manufacturing efficiency and profitability.