Leave Your Message

In today's rapidly evolving manufacturing landscape, optimizing production efficiency is paramount for maintaining a competitive edge. According to a recent report from the International Journal of Advanced Manufacturing Technology, manufacturers employing advanced welding technologies can increase productivity by up to 20%. Among these innovations, the Ultrasonic Card Slab Welder stands out as a game-changer, offering remarkable benefits such as reduced cycle times and improved bond quality. With the ability to join materials at lower temperatures, this technology minimizes the thermal impact on components, thus enhancing their durability and performance. As industries increasingly seek ways to streamline operations and reduce costs, understanding how to effectively implement an Ultrasonic Card Slab Welder will be crucial in driving operational success and meeting market demands.

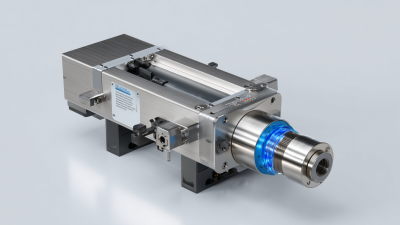

Ultrasonic card slab welding technology has gained attention for its ability to enhance production efficiency while ensuring high-quality joins. This technology utilizes ultrasonic vibrations to create heat at the interfaces of materials, facilitating a seamless bonding process without the need for additional adhesives or extensive fixtures. As manufacturers look for ways to optimize efficiency and reduce costs, understanding the fundamentals of ultrasonic welding becomes essential. This process not only minimizes production time but also increases the durability of the final product, making it a preferred choice in various industries.

When comparing ultrasonic and optical technologies in applications like in-display fingerprint scanning, each has its unique advantages. Ultrasonic scanners offer superior performance in challenging conditions, such as wet or dirty fingers, thanks to their ability to penetrate through layers and read the 3D map of a fingerprint. On the other hand, optical scanners are often simpler and more cost-effective but may struggle under certain conditions.

As industries shift towards adopting advanced technologies for consumer devices, the choice between ultrasonic and optical methods hinges on specific application needs and user preferences. Understanding these differences is key to making an informed decision on which technology best fits a particular use case.

Ultrasonic welding has emerged as a game-changer in manufacturing processes, especially when it comes to optimizing production efficiency. One of the key advantages of ultrasonic welding is its speed; it allows for quick bonding of materials without the need for additional adhesives or heating elements. This not only accelerates the production cycle but also reduces the time and resources typically consumed by conventional welding methods. The ability to join various materials, including plastics and metals, makes ultrasonic welding a versatile option for many industries, enabling greater flexibility in production lines.

Another significant benefit is the precision that ultrasonic welding offers. The focused energy ensures minimal thermal distortion and a strong bond, reducing the likelihood of defects and rework. This precision translates to less material waste and a lower energy footprint, contributing to both cost savings and a more sustainable production process. As manufacturers increasingly pursue innovative solutions to enhance efficiency, ultrasonic welding stands out as a reliable method that meets the demands of modern production environments. Whether in automotive, electronics, or packaging sectors, the implementation of ultrasonic card slab welders can lead to substantial improvements in productivity and product quality.

Setting up an ultrasonic welding system effectively can significantly enhance production efficiency. First and foremost, it’s crucial to ensure that the machine is correctly calibrated. Regularly check the frequency and power settings to match the specific materials being joined. This optimization will not only improve weld quality but also reduce scrap rates. Furthermore, keeping the machine clean and well-maintained is essential to ensure consistent performance.

Another important aspect is the selection of proper tooling. Using high-quality ultrasonic horns and boosters can greatly influence weld strength and quality. It’s advisable to invest in tooling tailored for the specific application, as this can lead to better energy transfer during the welding process.

Lastly, conducting regular training for operators can lead to better handling of the ultrasonic welding equipment. Educating them on best practices, such as the correct positioning of parts, can significantly reduce the likelihood of errors during production. Emphasizing continuous education and skill development will create a more proficient workforce, ultimately contributing to higher efficiency and output in the production line.

| Parameter | Optimal Value | Impact on Efficiency |

|---|---|---|

| Ultrasonic Frequency (kHz) | 20-40 | Higher frequency improves weld quality but may reduce penetration |

| Welding Pressure (kg/cm²) | 5-15 | Optimal pressure enhances joint strength |

| Welding Time (s) | 0.1-1 | Shorter times reduce energy use but may impact quality |

| Cooling Time (s) | 2-5 | Proper cooling prevents material warping |

| Material Thickness (mm) | 0.5-5 | Material thickness affects energy requirements |

| Alignment Accuracy (mm) | ±0.01 | High accuracy minimizes defects |

Ultrasonic card slab welding is a technology that offers significant advantages in production efficiency, but it is not without its challenges. One common issue is the difficulty in achieving consistent weld quality across various materials. A report by the International Journal of Advanced Manufacturing Technology highlights that 35% of production defects in ultrasonic welding stem from improper settings such as frequency and amplitude miscalibration. To address this, implementing real-time monitoring systems can adjust parameters dynamically, ensuring optimal conditions are maintained and reducing scrap rates significantly.

Another challenge faced by manufacturers is the fatigue and wear of ultrasonic horns, which can lead to decreased performance over time. According to a study from the Welding Institute, about 25% of downtime in ultrasonic welding processes is due to maintenance and replacement of these crucial components. Regular ultrasonic horn profiling and optimization of material selection for longer-lasting horns can mitigate this issue, ultimately leading to increased uptime and productivity in manufacturing environments. By focusing on these challenges and their solutions, companies can harness the full potential of ultrasonic welding technology for enhanced production efficiency.

The use of an ultrasonic card slab welder can significantly boost production efficiency in various industries. According to a report by the International Welding Institute, manufacturers leveraging advanced welding techniques, such as ultrasonic welding, have reported improvements in production speed of up to 30%. This is primarily attributed to the swift bonding capabilities of ultrasonic technology, which allows for immediate integration of components without the need for additional adhesives or mechanical fastening methods.

To accurately measure and analyze these efficiency improvements, companies often utilize key performance indicators (KPIs) such as cycle time reduction, yield rates, and downtime statistics. A study by the Manufacturing Performance Institute indicates that businesses that implement precise monitoring and data collection strategies can enhance production efficiency by an additional 20%. By analyzing production data collected from ultrasonic welders, companies can pinpoint bottlenecks and optimize workflows, leading to substantial cost savings and increased output.

These insights not only bolster overall productivity but also ensure high-quality outcomes, essential for maintaining competitiveness in today’s market.