Leave Your Message

In today’s fast-paced manufacturing landscape, efficiency is crucial. One tool that has gained popularity for its effectiveness is the Portable Ultrasonic Welder. This device is not only compact and lightweight, but it also provides powerful welding capabilities. Many industries rely on it for various applications, making it a versatile option.

When considering a Portable Ultrasonic Welder, key features come into play. Users often seek alternatives that do more, yet are easy to handle. Advanced control settings allow for precise adjustments. However, many overlook the importance of portability. A welder that is easy to transport can significantly enhance workflow.

Additionally, ease of use plays an essential role. While some welders have complicated setups, simplicity often yields better results. Prospective users should reflect on their unique needs and weigh these features carefully. Ultimately, recognizing the right balance of functionality and convenience will lead to greater efficiency in welding processes.

Portable ultrasonic welders offer many advantages across different applications. Their compact design allows for easy maneuverability. This feature is essential in tight spaces where traditional welding equipment would be impractical. The lightweight nature makes these welders ideal for on-site projects or remote locations.

Efficiency is another significant benefit. Ultrasonic welding provides a fast joining process, reducing production time. The precise control over welding parameters leads to better quality joints. For industries like automotive and textiles, this means less waste and higher output.

However, not all operators may be familiar with the specific settings for different materials. This can lead to imperfect welds if adjustments are not made. Training is crucial, yet often overlooked. Additionally, the maintenance of these machines can be demanding. Regular inspections are necessary to ensure optimal performance. Many users might neglect this, leading to inconsistent results over time.

| Feature | Description | Key Advantages | Applications |

|---|---|---|---|

| Portability | Lightweight and compact design for easy transport and storage. | Ideal for on-site welding with minimal setup. | Electronics, automotive, and plastic assembly. |

| Energy Efficiency | Operates at lower power consumption compared to traditional welding methods. | Reduces operating costs and environmental impact. | Medical devices, packaging, and textiles. |

| Versatility | Capable of welding a variety of materials, including thermoplastics and metals. | Facilitates diverse project requirements. | Construction, automotive, and electronics. |

| Speed | Fast welding cycles, allowing for high throughput. | Increases production efficiency and reduces lead times. | Mass production of components and assemblies. |

| Precision | Provides accurate and consistent welds with minimal deformation. | Ensures product quality and reduces waste. | Aerospace, medical devices, and consumer products. |

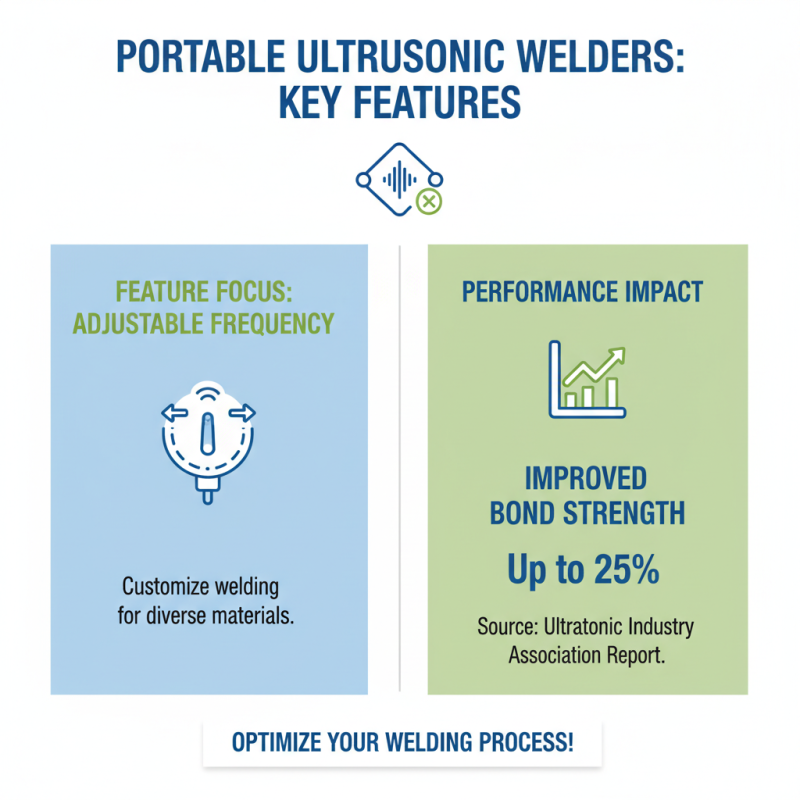

When considering portable ultrasonic welders, key features can significantly affect performance. Look for a model with adjustable frequency settings. This feature allows users to customize the welding process for various materials. A report from the Ultrasonic Industry Association indicates that optimal frequency can improve bond strength by up to 25%.

Portability is crucial. A lightweight design enhances usability on different job sites. It’s easier to handle, which can reduce fatigue during long sessions. Many users overlook battery life. Short battery life can halt production. Aim for a welder that offers at least 2 hours of continuous use.

Tip: Prioritize welders with powerful transducers. They are essential for efficient energy conversion. A well-designed ultrasonic welder also has user-friendly controls. Simplicity helps new users adapt quickly. A report highlights that complicated interfaces can lead to errors in 30% of first-time operations.

Consider build quality, too. It should withstand tough environments. A portable welder often endures varied conditions, so durability is key. Users sometimes pick sleek designs over rugged ones, but this can impact long-term investment. Always balance aesthetics with functionality for the best results.

Ultrasonic welding is a unique technology that uses high-frequency ultrasonic vibrations to join materials. The process involves clamping the materials together and applying vibration to create localized melting. This method is highly efficient and suitable for thermoplastics and metals. Reports indicate that ultrasonic welding can achieve joint strengths exceeding 80% of the base material's strength.

A standout feature of ultrasonic welding is its speed. It can perform welds in seconds, significantly reducing production time. Findings show that manufacturers can save up to 30% on labor costs due to the rapid cycle times of this method. In contrast, traditional welding techniques may take much longer, which can hinder productivity.

However, it is crucial to consider the skill level required for operation. Not everyone can master this technology easily. Proper training is necessary to operate these machines effectively. Additionally, material compatibility can be a challenge. Not all materials are suitable for ultrasonic welding. Engineers often face difficulties when selecting appropriate materials that provide optimal joint quality. Addressing these complexities can enhance the overall effectiveness of ultrasonic welding systems.

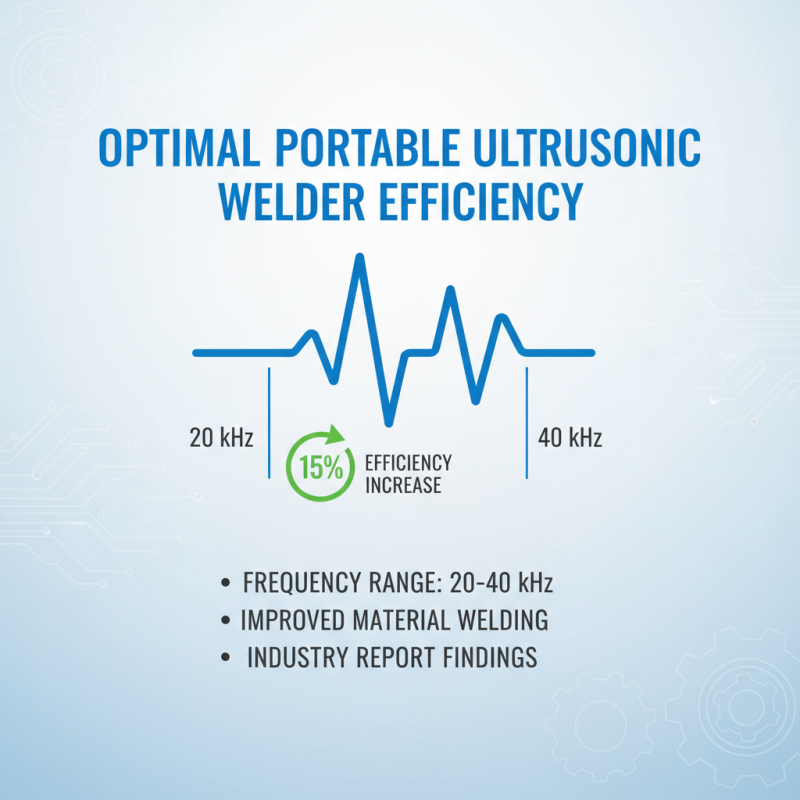

When selecting a portable ultrasonic welder, several factors are crucial for efficiency. First, consider the frequency range. Most efficient welders operate between 20 kHz to 40 kHz. This range provides optimal performance for various materials. According to a recent industry report, welders within this frequency range offer a 15% efficiency increase over those outside it.

Power is another key factor. Look for models featuring adjustable power settings, as this allows for flexibility. You want to achieve the right balance between power and control. A well-balanced welder minimizes material distortion, a common issue with high-output settings. Research indicates that programmable welders can reduce errors by up to 30%, enhancing overall quality.

Portability also matters. The weight and design influence usability in tight spaces. Many operators find that a lightweight welder can significantly reduce fatigue during extended use. Investing in a model with ergonomic features is wise. However, it's essential to ensure that portability does not compromise durability. An imbalance in design may lead to frequent maintenance, which needs reflection.

Proper maintenance of portable ultrasonic welders is crucial for optimal performance. Regular inspections can prevent costly breakdowns. According to industry reports, a well-maintained welder can improve efficiency by up to 40%. Skipping maintenance tasks could lead to decreased productivity.

One common issue is overheating. This can occur if the cooling system is not regularly checked. Overheating damages internal components and shortens the machine’s lifespan. Another frequent mistake is neglecting to clean the ultrasonic stack. Residue buildup can hinder performance and cause defective welds. Small changes can make a big difference.

**Tip:** Always clean the welding tips after every use. This simple task enhances the welder's efficiency.

Creating a maintenance schedule is vital. Allocate time for daily, weekly, and monthly checks. For instance, inspect cables weekly for signs of wear. This can prevent unexpected outages. Remember, only you can ensure your equipment works effectively. Regular attention to these details will keep your welders in top shape.