Leave Your Message

In the evolving landscape of manufacturing technologies, Electric Ultrasonic Welders have emerged as pivotal tools, revolutionizing the way materials are joined. According to a recent industry report by Research and Markets, the global ultrasonic welding equipment market is projected to reach USD 1.28 billion by 2025, growing at a CAGR of 5.6% from 2020. This growth underscores the increasing demand for high-efficiency and cost-effective joining solutions across various sectors, including automotive, electronics, and medical device manufacturing.

Choosing the right Electric Ultrasonic Welder requires a comprehensive understanding of both the technology and your specific application needs. With advancements in ultrasonic technology, features such as adjustable frequency, power control, and automated systems have become standard, providing manufacturers with enhanced precision and efficiency. Furthermore, detailed analysis from the International Journal of Advanced Manufacturing Technology indicates that ultrasonic welding not only reduces material waste but also minimizes energy consumption, making it a sustainable choice in today's eco-conscious market.

As industries strive for higher productivity and lower operational costs, selecting the most suitable Electric Ultrasonic Welder becomes crucial. This guide aims to equip you with the essential knowledge and factors to consider, ensuring that your investment aligns with both your production goals and compliance requirements in an increasingly competitive landscape.

Electric ultrasonic welding technology is a key advancement in the field of manufacturing, providing a fast and efficient method for joining materials. This process relies on high-frequency ultrasonic vibrations to create localized heating at the interface of the materials being welded, allowing them to meld together without the need for additional heat sources or adhesives. The precision of ultrasonic welding makes it especially useful for delicate and thin materials, where traditional welding methods may cause damage or excessive thermal distortion.

One of the critical advantages of electric ultrasonic welding lies in its versatility and adaptability. It can be employed across a range of industries, including automotive, electronics, and medical device manufacturing. The technology offers not only speed in production but also consistency and reliability in producing high-quality welds. By selecting the right ultrasonic welder, manufacturers can optimize their processes for specific applications, enhancing overall efficiency while reducing waste and improving product integrity. Understanding the various parameters that influence ultrasonic welding, such as frequency, amplitude, and pressure, is essential for achieving the best results tailored to specific material combinations and production requirements.

| Model | Frequency (kHz) | Power (W) | Welding Width (mm) | Weight (kg) | Price ($) |

|---|---|---|---|---|---|

| Model A | 20 | 3000 | 50 | 15 | 1500 |

| Model B | 40 | 5000 | 70 | 18 | 2500 |

| Model C | 28 | 4000 | 60 | 20 | 2000 |

| Model D | 30 | 4500 | 65 | 17 | 2300 |

| Model E | 35 | 5500 | 80 | 22 | 3000 |

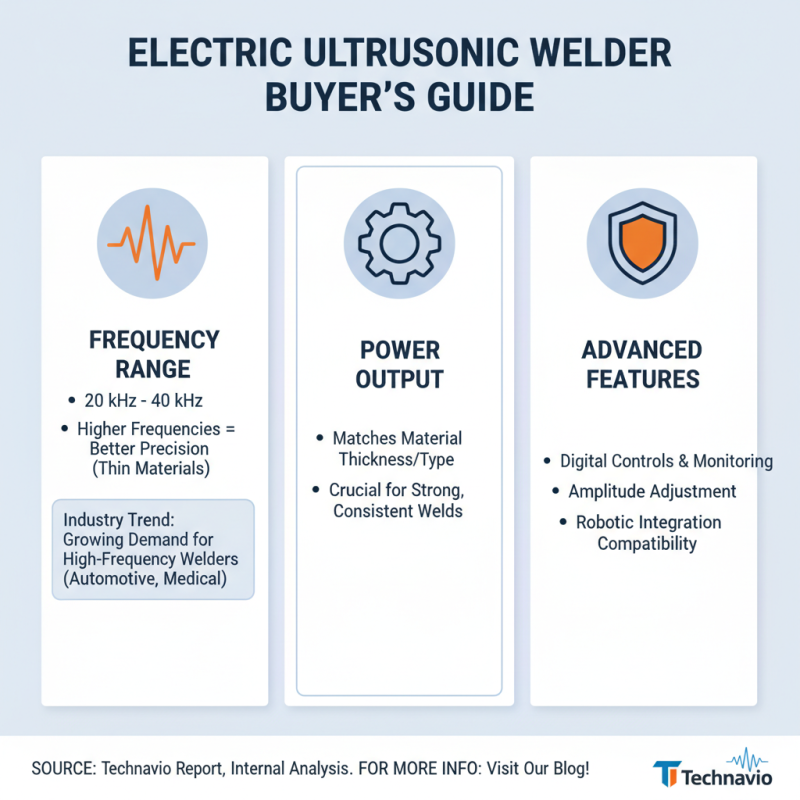

When choosing the best electric ultrasonic welder for your needs, it's essential to focus on several key features that can significantly impact performance and efficiency. One of the primary considerations is the frequency range of the machine. Generally, ultrasonic welding machines operate between 20 kHz and 40 kHz, with higher frequencies delivering better precision for thinner materials. According to a report by Technavio, the demand for higher frequency welders is projected to grow as industries seek more advanced solutions for delicate components in sectors like automotive and medical devices.

Another important aspect is the power of the ultrasonic welder. Adequate power ensures strong and reliable welds, particularly for thicker materials. A welder with variable power settings can offer greater flexibility, allowing operators to adjust the welding energy based on the material and thickness. The performance metrics from industry analysis suggest that machines providing a power range of 600 watts to 3000 watts are most versatile across a wide array of applications.

Tips: Always evaluate the machine's transducer technology, as advanced materials can enhance weld quality and durability. Additionally, consider the machine's ease of use and maintenance requirements; a user-friendly interface can significantly reduce downtime and improve overall productivity. Furthermore, ensure that the welder has a good thermal management system to prevent overheating during prolonged use.

When selecting an electric ultrasonic welder, evaluating your specific welding needs and applications is critical. The types of materials you plan to weld, the thickness of those materials, and the production volume required all play a pivotal role in determining the best welder for your situation. According to industry reports, the ultrasonic welding market is projected to grow significantly, with an expected CAGR of 8.3% from 2021 to 2026. This growth highlights the increasing demand for efficient and precise welding solutions across various sectors, including automotive, electronics, and medical devices.

Understanding the materials involved is essential. Ultrasonic welding is particularly effective for thermoplastics and thin metals, making it suitable for applications such as bonding plastic components in consumer products or creating robust seals in medical packaging. Studies suggest that the optimal frequency for ultrasonic welders typically ranges from 20 kHz to 70 kHz. Factors like the geometry of the parts to be joined and the required joint strength can affect the choice of frequency, tooling design, and energy input, all of which are crucial for achieving desirable weld quality.

Moreover, consider the operational costs and maintenance requirements associated with different welder models. Reports indicate that improper machine selection and maintenance can lead to increased downtime and faulty welds, which can significantly impact production efficiency. Investing time in understanding your specific applications will ultimately contribute to making a well-informed decision that aligns with both your operational objectives and budget constraints.

When selecting an electric ultrasonic welder, understanding the top brands and models available in the market is crucial for meeting specific industrial needs. According to a recent industry analysis by ResearchAndMarkets, the global ultrasonic welding equipment market is projected to grow at a CAGR of 7.5% from 2022 to 2030. This growth can be attributed to the increasing demand for high-quality joining solutions across various sectors, including automotive, electronics, and medical device manufacturing. Leading brands often incorporate advanced technology that enhances precision and efficiency, making it vital to consider both reliability and performance when evaluating your options.

Key features to assess include power output, frequency range, and the size of the weld area. Top models are designed to accommodate varying materials, such as thermoplastics and metals, ensuring versatility in applications. A report by MarketsandMarkets highlights that ultrasonic welders with adjustable parameters enable manufacturers to optimize production processes, thereby reducing waste and increasing overall productivity. Additionally, robust customer support and warranty options offered by reputable brands can significantly impact long-term satisfaction and operational continuity. By carefully analyzing these aspects, you can choose an ultrasonic welder that aligns perfectly with your operational requirements.

Maintaining ultrasonic welders is crucial for ensuring optimal performance and longevity. Regular maintenance not only enhances the efficiency of the machines but also reduces downtime, which can be detrimental in high-volume production environments. According to a report by the International Ultrasonic Welding Association, proper care and maintenance can increase the lifespan of ultrasonic welding equipment by up to 30%. Key maintenance practices include routine inspection of the ultrasonic stack, which comprises the transducer, booster, and sonotrode. Regularly checking for wear, misalignment, or damage can help in detecting issues before they lead to equipment failure.

Best practices for ultrasonic welders also extend to their operational procedures. Training operators to correctly set parameters such as amplitude, force, and time is essential to ensure high-quality welds. Inconsistent welding conditions can lead to defective products, impacting not only production efficiency but also customer satisfaction. Data from recent studies show that improper parameter settings can increase rejection rates by as much as 25%. Furthermore, keeping the work area clean and organized minimizes contamination risks, which can affect both the welding process and product quality. By integrating these maintenance and operational practices, firms can maximize their investments in ultrasonic welding technology and improve overall productivity.