Leave Your Message

In the ever-evolving landscape of manufacturing and production, the demand for efficient and precise joining techniques has surged. Among these, ultrasonic welding stands out as a preferred method, offering speed and reliability for a variety of materials. As businesses seek to enhance their operational efficiency while maintaining high-quality standards, the need for expert services has become imperative. This is where the concept of an "Ultrasonic Welder For Hire" emerges as a practical solution for many companies.

In 2023, finding the best ultrasonic welder for hire services near you has become increasingly accessible, catering to diverse industry needs. By opting for rental services, organizations can leverage state-of-the-art ultrasonic welding technology without the heavy investment in purchasing equipment outright. These services not only provide flexibility but also ensure that you have access to skilled professionals who can execute projects with precision and expertise.

As we explore the various options available for ultrasonic welder hire, it is essential to consider factors such as service quality, range of capabilities, and proximity to your location. With a wealth of choices in 2023, businesses are better positioned than ever to find the right ultrasonic welding services that meet their specific requirements, ultimately driving innovation and enhancing productivity in their operations.

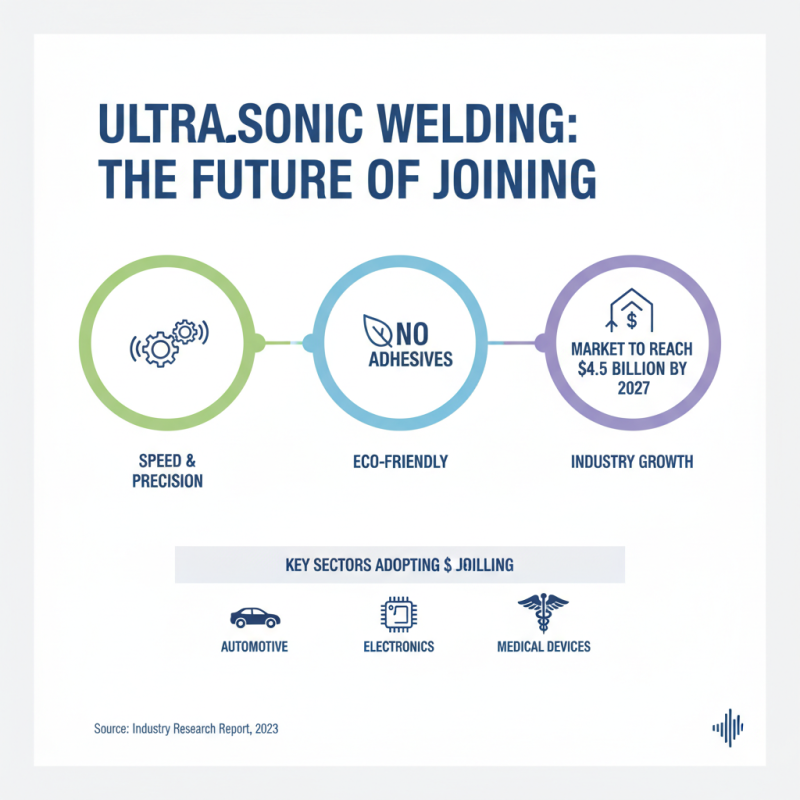

Ultrasonic welding is a revolutionary joining technique that utilizes high-frequency ultrasonic vibrations to weld materials, typically thermoplastics. This process not only offers speed and precision but also minimizes the need for additional materials like adhesives, making it an environmentally friendly choice. According to a report by Industry Research, the ultrasonic welding market is projected to reach $4.5 billion by 2027, highlighting the increasing adoption of this technology across various sectors, such as automotive, electronics, and medical devices.

One of the key advantages of ultrasonic welding is its ability to produce strong, durable bonds without thermal stress, which is crucial for sensitive electronic components. For instance, in the automotive industry, ultrasonic welding is used in the assembly of safety-critical parts, ensuring quality and reliability. Moreover, the medical sector leverages this technology for manufacturing durable and sterile devices, showcasing its broad applicability.

Tips: When considering ultrasonic welding services, evaluate the provider's expertise and equipment capabilities. Ensure they have experience in your specific industry to achieve the best results. Additionally, request samples or case studies to understand their welding process and quality standards, which can significantly affect the performance of the final products.

When searching for the best ultrasonic welder for hire services, it's essential to establish clear criteria to ensure you make an informed decision. One primary factor to consider is the provider’s experience and expertise in the industry. According to a report from the Ultrasonic Technology Association, companies with more than five years of experience tend to deliver more reliable and efficient welding solutions, as they have dealt with a variety of materials and applications. Additionally, a provider’s technical knowledge and familiarity with specific ultrasonic techniques can significantly impact the quality of the welds produced.

Another critical criterion is the range of services and equipment offered. The ultrasonic welding process requires specialized machinery that varies in capabilities and specifications. A comprehensive analysis by the International Journal of Advanced Manufacturing Technology outlines that equipment with adjustable frequency settings can provide better results across different material types. It's also beneficial to select a service that can offer custom solutions tailored to your project needs, as this flexibility can lead to enhanced weld integrity and overall performance. Ultimately, ensuring that the ultrasonic welder you choose meets these technical and experiential benchmarks is vital for successful collaboration and project outcomes.

When searching for ultrasonic welder hire services in 2023, it's essential to conduct a comparative analysis of the options available. A reliable ultrasonic welder not only provides efficiency and precision in joining materials but also contributes to the overall productivity of manufacturing processes. In this landscape, service providers are distinguished by their equipment quality, technician expertise, responsiveness, and customer support.

One critical factor in this comparison is the technology used in the ultrasonic welding machines. Different hire services may offer varying machine capabilities, such as adjustable frequency settings, power ratings, and custom tooling solutions. Additionally, evaluating the experience and qualifications of the technicians can provide insight into the service's operational capacity. A skilled technician can enhance the welding process, ensuring that the materials are joined effectively and with minimal defects.

Furthermore, the hiring process itself can significantly impact your project timelines. Areas to consider include the flexibility of hire agreements, availability of machines on short notice, and ongoing maintenance support during the rental period. The best ultrasonic welder hire services will not only meet your immediate requirements but also provide added value through continuous assistance and guidance throughout your welding projects.

When considering ultrasonic welder rental services, understanding the cost factors involved is crucial for effective budgeting. Rental prices can vary based on several parameters, including the type of ultrasonic welder required, the duration of the rental period, and any additional services such as training or technical support. Equipment with advanced features or higher power ratings typically commands a higher rental price, so it’s important to assess the specific needs of your project to avoid overpaying for unnecessary capabilities.

Additional cost considerations may include transportation fees, insurance requirements, and maintenance services. Some rental companies might provide delivery and setup, which can add to the total cost, but this service can also save time and effort. It's advisable to request a detailed breakdown of costs from the rental provider and compare various options to ensure you receive the best value for your investment.

By meticulously planning your budget, you can effectively harness ultrasonic welding technology without overspending, ensuring the success of your project within financial constraints.

When considering projects that require ultrasonic welding, hiring skilled ultrasonic welders can offer significant advantages over investing in purchasing equipment. One of the primary benefits is cost-effectiveness. Purchasing ultrasonic welding machines involves a significant upfront investment, along with ongoing maintenance and operational costs. By opting for hire services, organizations can utilize high-quality equipment and expertise without the burden of ownership expenses. This allows businesses to allocate resources more efficiently and focus on their core operations without the financial strain.

Another key benefit of hiring ultrasonic welders is access to specialized skills and knowledge. Professional ultrasonic welders have extensive training and experience, which ensures that the process is executed with precision and quality. This expertise can be particularly beneficial for projects requiring specific techniques or materials. Additionally, hiring allows companies to scale their workforce according to project demands, providing flexibility that in-house equipment and personnel may not offer. This adaptability ensures that businesses can meet fluctuating production needs without compromising on quality or timelines.