Leave Your Message

The Ultrasonic Welding Machine is a powerful tool in industrial applications. It uses high-frequency sound waves to join materials. For both beginners and experts, mastering this technology is essential. Understanding how it works will improve the quality of your projects.

Beginners may struggle with settings and material compatibility. It's important to learn about the right frequencies and pressure settings. Experts should also revisit the basics to refine their techniques. Even small adjustments can lead to significant improvements in weld quality.

Practical experience is vital. Trial and error can reveal potential issues. Pay attention to the details, like the amplitude and sealing time. Reflecting on past projects can guide future efforts. By sharing tips and insights, we can enhance our skills with the Ultrasonic Welding Machine together.

Ultrasonic welding is a unique joining technique, using high-frequency sound waves. This process creates heat through friction, allowing materials to bond without additional adhesives. It is especially useful for plastics and thin metals. A recent report indicated that the ultrasonic welding market is expected to grow at a CAGR of 8.5% between 2022 and 2030. This demonstrates a rising interest in efficient manufacturing methods.

Understanding the basics is crucial for both beginners and experts. Operators must pay close attention to parameters like amplitude, pressure, and time. An improper setting can lead to weak joints, which often results in product failure. Experienced users sometimes overlook these details, thinking they know what works best. Mistakes can lead to costly rework and delays.

Moreover, monitoring the ultrasonic welding process can be tricky. Many operators rely on visual cues or instinct. However, data-driven approaches can yield better results. Research shows that machines equipped with smart technology can improve consistency by up to 15%. A focus on data is essential for optimizing performance and avoiding errors.

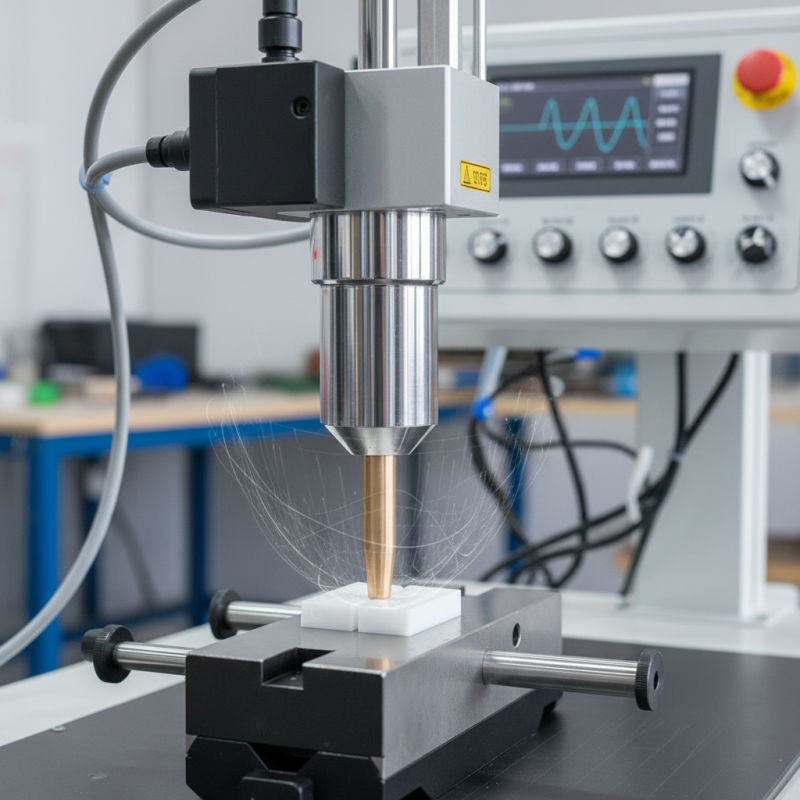

Ultrasonic welding machines play a crucial role in various industries. Understanding their key components can enhance your welding experience. The primary parts include a generator, transducer, booster, and sonotrode. Each component has a unique function that contributes to effective welding.

The generator converts electrical energy into high-frequency signals. This is the starting point of the process. The transducer then transforms these signals into mechanical vibrations. The booster amplifies these vibrations before they reach the sonotrode. This step is vital for achieving a strong bond in your materials.

For beginners, familiarize yourself with each component's role. This knowledge aids in troubleshooting when issues arise. Experienced users should regularly check their machines for wear and tear. A worn transducer can lead to inadequate welds. Always ensure your components are clean and well-maintained. If you're not mindful, subpar performance may occur, leading to wasted materials. Remember, practice makes perfect, but reflection on past mistakes leads to improvement.

Operating an ultrasonic welding machine requires careful attention to detail. Start by ensuring your work area is clean and organized. This helps prevent contamination of your materials. Familiarize yourself with the machine’s controls. Each button and dial serves a unique purpose. Take time to read the manual; understanding the specifications is essential.

When preparing to weld, select appropriate materials. Not all plastics or metals are suitable for ultrasonic welding. Adjust the amplitude settings based on your material type. This adjustment can significantly impact the weld quality. Remember, achieving the perfect weld often requires experimentation. Mistakes provide insights into what works and what doesn’t.

After the initial setup, test your machine with sample pieces. Inconsistent welds may indicate incorrect parameters. Take notes on what settings yield the best results. Review these notes when troubleshooting. It’s easy to overlook minor details that lead to bigger issues later. Embrace the learning process; each weld is a new opportunity to refine your skills.

Ultrasonic welding offers a quick method to join materials. However, beginners may face common issues. Poor adhesion often arises from contaminated surfaces. Always ensure parts are clean before starting. This simple step can prevent many headaches later on. Sometimes, adjusting welding amplitude and pressure helps achieve a better bond.

Another problem is inconsistent welds. This can occur due to irregular material thickness. Monitoring material specifications is crucial. Ensure that you're using the right settings for each type of material. Overheating can also weaken the joint. Keep an eye on the temperature during the process to avoid damaging your components.

Some users experience excessive flash, which is the excess material that seeps out. This can create an unprofessional appearance. To combat this, adjust the weld parameters and keep a consistent pace during welding. Lastly, frequent maintenance of equipment is essential for optimal performance. Neglecting this can lead to larger issues down the line. Small tweaks can make a big difference. Listening to your machine’s feedback is vital.

Ultrasonic welding is a fascinating process that combines high-frequency sound waves to bond materials. For both beginners and experts, mastering this technology requires practice and understanding. Advanced techniques can help improve efficiency. Exploring these methods is essential for successful projects.

One advanced technique involves optimizing the amplitude settings. Different materials require varying amplitudes for the best results. Start with a low setting and gradually increase until you find the ideal level. This trial and error can save time and reduce mistakes.

A common tip is to ensure proper fixture alignment. Misalignment can lead to weak joints and wasted material. Regularly check fixtures and adjust them as necessary. Another technique is to fine-tune the duration of welds. Longer durations may not always yield better bonds; it often depends on the material. Adjusting these factors can lead to more successful outcomes.