Leave Your Message

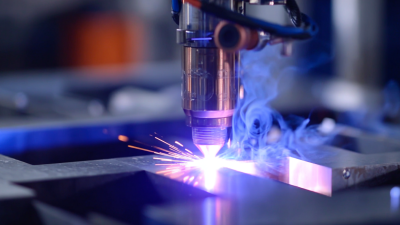

In the ever-evolving landscape of modern manufacturing, the importance of precision and efficiency cannot be overstated, particularly in the realm of electrical connections. Ultrasonic Wire Welding has emerged as a transformative technique that harnesses high-frequency ultrasonic vibrations to join wires with remarkable speed and consistency. As industries seek to push the boundaries of traditional practices, understanding the innovations surrounding the Ultrasonic Wire Welder becomes crucial.

This introduction will explore the groundbreaking methodologies and advancements in ultrasonic welding technology, emphasizing how they cater to diverse manufacturing needs and improve overall productivity. By delving into the "why" behind these innovations, we can uncover the rationale driving the adoption of ultrasonic welding solutions, shedding light on their impact across various sectors.

Innovative ultrasonic welding techniques are rapidly transforming modern manufacturing processes, particularly in industries such as automotive and aerospace. Recent advancements have focused on integrating ultrasonic welding with thermoplastic composites, leading to more efficient and eco-friendly manufacturing practices. For instance, companies are now exploring how ultrasonic welding can enhance the production of disposable hygiene products by adapting to new raw material types, which simplifies the design and production workflow.

Tips: When considering ultrasonic welding for your manufacturing needs, it’s essential to assess the compatibility of materials and the specific requirements of your production processes. Emphasizing design optimization can lead to significant improvements in both mechanical properties and overall efficiency.

Additionally, as the electric vehicle market continues to grow, the incorporation of ultrasonic welding techniques presents a promising avenue for enhancing EV component manufacturing. Notably, the synergy between ultrasonics and advanced manufacturing methods is paving the way for innovations that underline quality and reliability in component production. Engaging with the latest technologies can empower manufacturers to stay ahead in the competitive landscape.

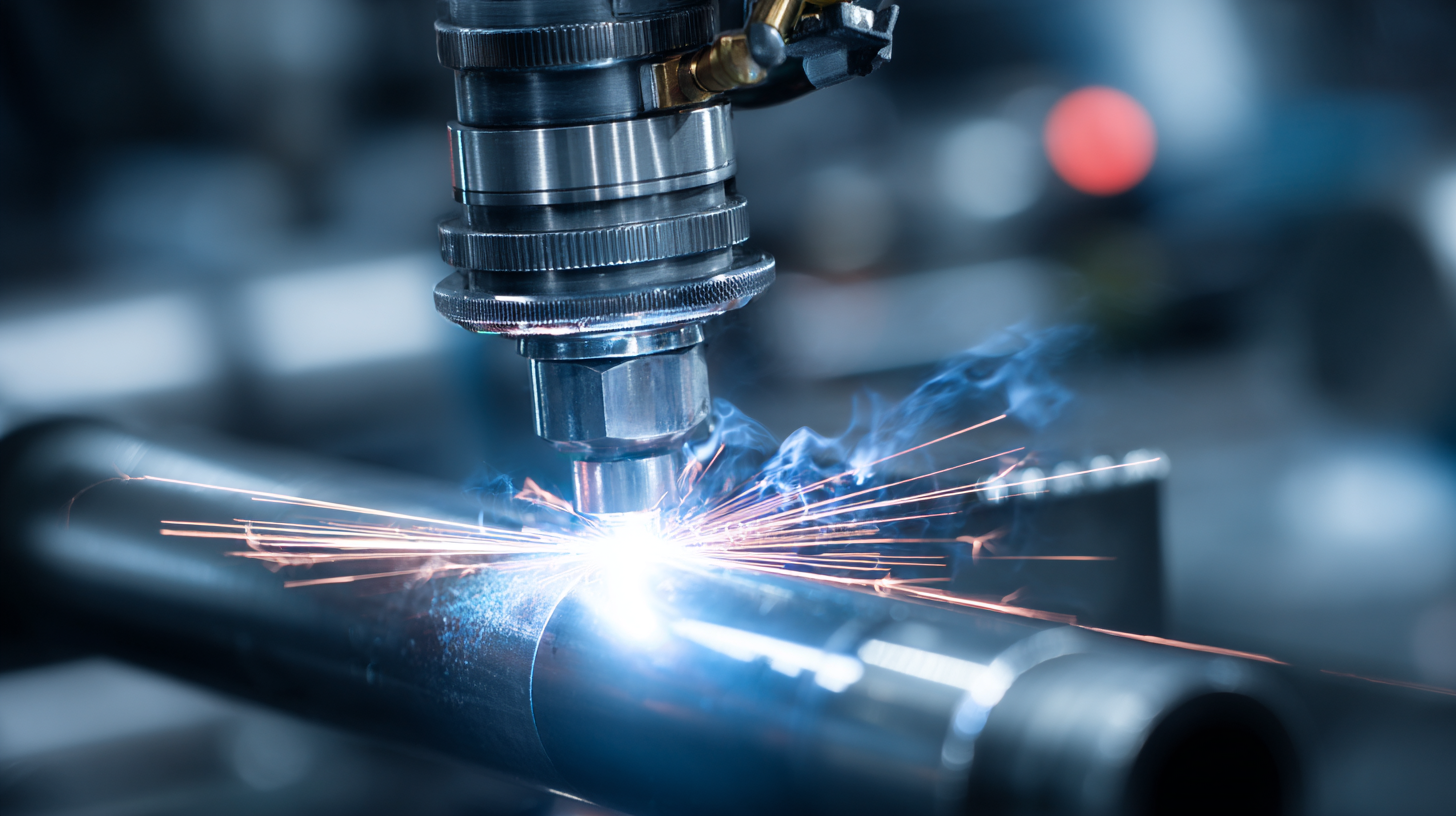

In ultrasonic wire welding, achieving superior weld quality and consistency is paramount for modern manufacturing demands. One of the key strategies to enhance weld quality is to ensure precise control of the ultrasonic parameters, such as frequency, amplitude, and welding time. A thorough understanding of the material characteristics and their response to ultrasonic energy can significantly influence the weld integrity. For instance, selecting the right wire material and adjusting the parameters according to its thermal and mechanical properties can prevent issues such as overheating or insufficient bonding.

Additionally, implementing a rigorous inspection and testing regimen can help identify and address potential defects early in the production process. Techniques like real-time monitoring of weld performance and utilizing advanced imaging systems can provide valuable insights into the weld process, allowing for immediate adjustments if necessary. Furthermore, training operators on the nuances of ultrasonic welding equipment can lead to improved consistency and reduced variability, ensuring that every weld meets the stringent quality standards required in today’s competitive marketplace.

| Welding Parameter | Optimal Value | Impact on Weld Quality | Comments |

|---|---|---|---|

| Frequency (kHz) | 20 | Higher energy for efficient bonding | Optimal frequency ensures effective energy transfer |

| Amplitude (μm) | 50 | Increased penetration and union strength | Careful tuning required to prevent damage |

| Welding Time (ms) | 5 | Critical for sufficient material melting | Excess time can lead to overheating |

| Pressure (N) | 10 | Ensures good material contact | Too high pressure can compress material |

| Material Type | Copper | Excellent conductivity and weldability | Consider compatibility with other materials |

| Surface Condition | Clean and Polished | Enhances weld uniformity and strength | Regular cleaning procedures are necessary |

The integration of automation with ultrasonic wire welding technology is revolutionizing modern manufacturing processes. By combining these two advanced techniques, manufacturers can achieve significant improvements in efficiency and consistency. Automation helps streamline workflows, reducing human error and minimizing cycle times, while ultrasonic technology provides precise and reliable bonding of metals and other materials without the need for solder or adhesives. This synergy not only enhances productivity but also allows for a more flexible manufacturing setup, capable of adapting to various production demands with ease.

Moreover, implementing automated ultrasonic welding systems facilitates real-time monitoring and control of the welding process. Sensors and software can track parameters such as temperature and pressure, ensuring optimal conditions are maintained throughout each weld. This level of oversight contributes to higher quality results and decreases the likelihood of defects, ultimately leading to reduced material waste and lower costs. As industries continue to seek innovative solutions to meet increasing demands, the fusion of automation and ultrasonic technology will play a critical role in shaping the future of manufacturing.

Material selection is crucial in the realm of ultrasonic wire welding, as it directly influences the effectiveness and quality of the welding process. Different materials exhibit varied acoustic properties, thermal conductivities, and mechanical strengths, which can significantly affect the bonding outcomes. For instance, metals like aluminum and copper have high thermal conductivity, making them ideal candidates for ultrasonic welding due to their efficient energy transfer during the process. Conversely, other materials, such as certain plastics or composites, might require tailored approaches to achieve optimal results.

In addition to material properties, surface preparation plays a key role in successful ultrasonic welding. The cleanliness and texture of the materials can affect how ultrasound energy is transmitted and absorbed at the weld interface. Even minor contaminants can lead to weak joints, highlighting the importance of rigorous surface cleaning protocols. Understanding these material characteristics and preparing them appropriately allows manufacturers to enhance weld strength, improve production efficiency, and reduce the risk of defects, ultimately leading to superior product performance in modern manufacturing environments.

As the trend toward advanced manufacturing continues to accelerate, ultrasonic wire welding is emerging as a crucial technique for modern production environments. With the U.S. welding consumables market projected to grow significantly, manufacturers must stay informed about the innovations and techniques transforming this field. Ultrasonic welding, particularly in wire applications, offers distinct advantages, including reduced heat distortion and remarkable speed, making it exceptionally suitable for sectors like aerospace and electronics.

**Tips:** When considering ultrasonic welding for your manufacturing needs, ensure that you select the right frequency and power settings to optimize weld quality. Additionally, investing in training for operators can enhance productivity and reduce errors, leading to consistent results.

Furthermore, emerging technologies such as digital twins and advanced manufacturing processes are reshaping how ultrasonic welding is integrated within production lines. Manufacturers should explore these advancements as they promise increased efficiency and better quality control. Staying abreast of these trends not only improves operational capabilities but also positions manufacturers to compete effectively in a rapidly evolving market.

**Tips:** Regularly update your equipment and software to include the latest features that enhance accuracy and reliability. Collaborating with technology providers can also lead to customized solutions tailored to specific industry demands.