Leave Your Message

In the rapidly evolving landscape of modern manufacturing, the quest for innovation and efficiency drives companies to explore advanced technologies that enhance production processes. One of the groundbreaking advancements in this domain is the Ultrasonic Cable Welder, a sophisticated tool that revolutionizes the way cables are joined. By utilizing high-frequency ultrasonic vibrations, this technology enables seamless and strong connections, thereby improving the reliability and performance of manufactured products.

The significance of the Ultrasonic Cable Welder extends beyond mere functionality; it represents a pivotal shift towards more sustainable manufacturing practices, as it reduces the need for consumables and minimizes material waste. As industries strive to meet the growing demands for high-quality, durable products, understanding the capabilities and implications of ultrasonic cable welding becomes essential. This introduction delves into the transformative potential of this technology, shedding light on its impact on the future of manufacturing and the industries that stand to benefit from its implementation.

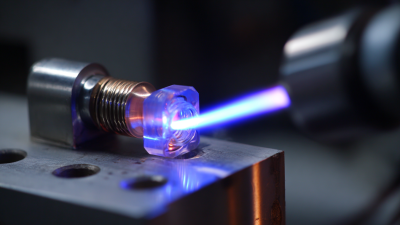

Ultrasonic cable welding technology represents a significant advancement in the manufacturing sector, particularly in the assembly of complex cable systems. At its core, this process utilizes high-frequency sound waves to generate heat at the interface of the materials being fused. This method allows for precise control of energy input, resulting in a strong and durable bond without compromising the integrity of the surrounding components. The ability to weld cables quickly and efficiently not only reduces manufacturing time but also enhances the overall quality of the product.

One of the most appealing aspects of ultrasonic welding is its versatility in different applications. It can be used with various materials, including metals and thermoplastics, making it ideal for industries ranging from automotive to electronics. Additionally, the process is clean and environmentally friendly, as it does not require adhesives or chemicals, thereby minimizing waste and potential pollution. As manufacturers continue to seek innovative and efficient methods of production, ultrasonic cable welding technology is poised to play a vital role in shaping the future of how products are designed and assembled in a wide array of fields.

| Dimension | Details |

|---|---|

| Technology Type | Ultrasonic Cable Welding |

| Process | Joining two cables using high-frequency ultrasonic vibrations. |

| Applications | Automotive, Aerospace, Electronics, Renewable Energy. |

| Advantages | High precision, reduced cycle time, lower energy consumption, and strong weld joints. |

| Key Components | Ultrasonic generator, booster, sonotrode, and fixture. |

| Challenges | Material compatibility, equipment cost, and technical expertise required. |

| Future Trends | Integration with automation, advanced materials, and Industry 4.0 concepts. |

Ultrasonic welding technology is revolutionizing the manufacturing landscape by offering significant advantages that enhance efficiency and reliability. One of the primary benefits is its ability to produce strong, high-quality joints without the need for additional adhesives or mechanical fasteners. This not only reduces material costs but also minimizes processing time, allowing manufacturers to produce more items in less time. The precision of ultrasonic welding also ensures that the integrity of the components is maintained, which is particularly crucial in industries such as automotive and aerospace.

Another key advantage of ultrasonic welding is its environmentally friendly nature. The process generates minimal waste and consumes less energy compared to traditional welding methods. This aligns with the growing emphasis on sustainability within manufacturing sectors.

Additionally, ultrasonic welding can be automated, streamlining the production process and reducing labor costs while maintaining consistent quality control. As industries continue to seek innovative solutions to stay competitive, the adoption of ultrasonic cable welding technology is poised to become a cornerstone of modern manufacturing practices.

The implementation of ultrasonic cable welding technology involves a precise and systematic process that can significantly enhance manufacturing efficiency. Initially, the design of the cable assemblies is crucial; ensuring that materials are compatible with ultrasonic welding helps to maximize bond strength and integrity. The selection of the right ultrasonic welder, which is finely tuned to the project's specific requirements, is a critical step that influences the overall outcome.

Once the equipment is in place, the next phase entails setting up the work environment, ensuring that surfaces are clean and free from contaminants. Following this, operators must position the cables accurately within the welding fixture, optimizing alignment to facilitate seamless bonding. The ultrasonic welding machine generates high-frequency vibrations that are applied to the cable ends, producing localized heat and resulting in a strong fusion without damaging the components. Monitoring the process in real-time is essential to guarantee quality, as any deviations could compromise the weld’s effectiveness. Through meticulous execution of these steps, manufacturers can leverage the advanced benefits of ultrasonic cable welding technology in their production lines.

Ultrasonic cable welding technology is revolutionizing manufacturing across various industries by providing efficient and reliable solutions for joining materials. One of the most common applications is in the automotive sector, where it is used for creating robust electrical connections within wiring harnesses. This method not only ensures strong welds that can withstand harsh conditions but also reduces the overall weight of vehicles, contributing to improved fuel efficiency.

Another significant use case is in the electronics industry, where ultrasonic welding is employed to attach delicate wires to circuit boards. This precision is crucial, as it minimizes the risk of damage to sensitive components while delivering reliable performance. Additionally, the medical device sector benefits from this technology, particularly in the assembly of medical cables and sensors, where the need for sterile environments and strong, durable connections is paramount. These applications highlight the versatile nature of ultrasonic cable welding, demonstrating its potential to enhance productivity and product quality across multiple fields.

Ultrasonic welding technology is rapidly transforming various sectors within manufacturing, especially in the production of plastic parts, electronic components, and medical devices. As industries embrace digital transformation, the demand for ultrasonic welding equipment continues to grow, projecting a significant market increase. Reports indicate that the ultrasonic plastic welding machine market, valued at approximately $320 million in 2022, is expected to reach $550 million by 2030, indicating a robust compound annual growth rate of 7.2% from 2024 to 2030. This growth highlights the crucial role ultrasonic welding plays in enhancing production efficiency and product quality.

Innovations in ultrasonic welding, such as the recent patent application for battery lid components, demonstrate the technology's potential in enhancing manufacturing processes in sectors like automotive. These advancements not only improve the structural integrity of components but also significantly elevate production quality. As the manufacturing landscape evolves, companies that leverage ultrasonic welding innovations will likely gain a competitive edge, tapping into new applications and improving operational efficiency. This trend signifies a promising future for manufacturers willing to invest in advanced welding technologies.