Leave Your Message

When considering the best options for your business needs, selecting an Ultrasonic Welder Factory can be a game-changing decision. John Doe, an industry expert with over 20 years of experience in ultrasonic technology, states, "Choosing the right factory impacts the quality and efficiency of your production." His insight highlights the importance of this choice in a competitive market.

Ultrasonic welding offers precision and speed. Industries such as automotive and electronics greatly benefit from these advanced technologies. A reliable Ultrasonic Welder Factory provides not just equipment but also engineering support. Some businesses overlook this, leading to inefficiencies. It's essential to evaluate how a factory aligns with your production goals.

Investing in quality machinery is vital. However, many companies rush through this process. They may choose based solely on pricing, neglecting long-term benefits. It’s crucial to reflect on past strategies and refine your selection process. A factory’s reputation for quality and service can make all the difference in your operations.

Ultrasonic welding technology utilizes high-frequency ultrasonic vibrations to create strong, durable bonds between materials. This method is widely used in industries like automotive, medical, and electronics. The global ultrasonic welding market is projected to reach $3 billion by 2026, reflecting its increasing adoption.

One key application of ultrasonic welding is in medical device manufacturing. The process allows for precise bonding without damaging sensitive components. Reports indicate this approach can reduce production time by 30%, enhancing efficiency. Additionally, ultrasonic welding is eco-friendly, as it often requires no adhesives or solvents.

Tip: Evaluate the design of your parts before choosing ultrasonic welding. Complex shapes may need adjustments for optimal results.

Another area of application is in packaging. Ultrasonic sealing ensures airtight closures for food products. This helps in maintaining freshness and extending shelf life. However, companies must monitor equipment regularly to prevent inconsistent quality.

Tip: Regular maintenance of ultrasonic welders is crucial to avoid quality issues. Scheduling frequent checks can help.

This chart illustrates the number of applications for ultrasonic welding technology in various industries, highlighting its versatility and importance in sectors such as automotive, medical devices, consumer electronics, textiles, and packaging.

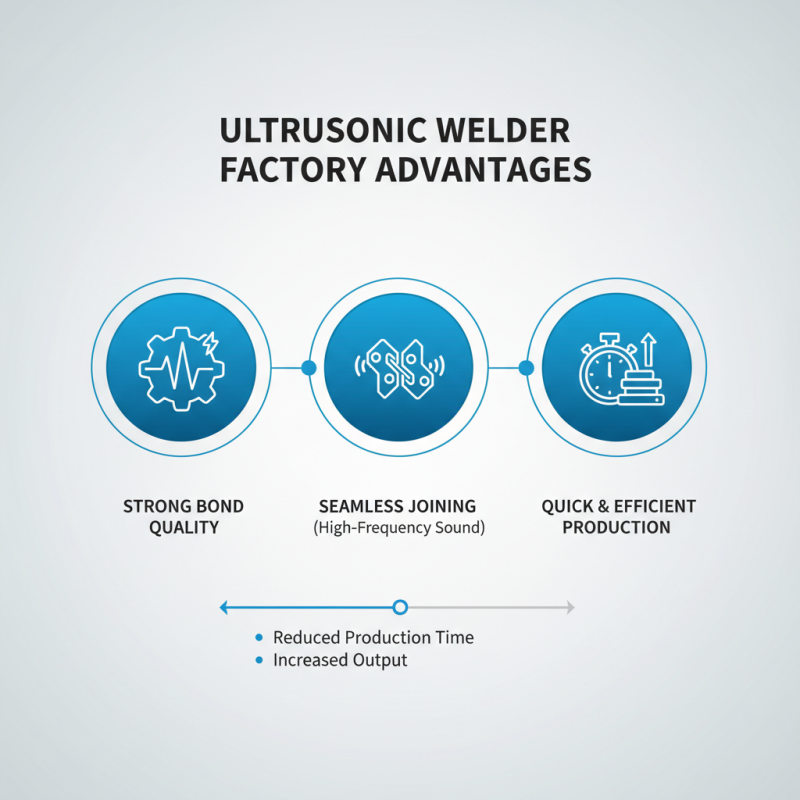

When considering an ultrasonic welder factory, several advantages become clear. These factories specialize in advanced technology that ensures strong bond quality. Ultrasonic welding uses high-frequency sound waves for seamless joining. This process is quick and efficient, reducing production time and increasing output.

Tip: Evaluate the factory's expertise. Look for their experience in your specific industry to ensure you receive tailored solutions.

Moreover, ultrasonic welding is energy-efficient. It consumes less energy compared to traditional methods. This not only lowers costs but also has a positive environmental impact. Factories usually have systems in place for waste reduction, further enhancing sustainability.

Tip: Investigate the materials used in the process. Using high-quality materials can lead to better weld strength and durability.

However, not every factory operates at the same level. Some may lack the necessary quality controls. It's essential to ask about their testing procedures. Understanding their commitment to quality can save you from future issues.

Choosing the right ultrasonic welder manufacturer can significantly impact your production. Start by assessing their experience. A factory with a proven track record often delivers better quality. Look for years in the industry, not just a flashy website. Review customer testimonials to gauge satisfaction.

Next, consider their technology. Are they using the latest ultrasonic technology? It’s crucial for efficiency. If they are stuck using outdated methods, it may reflect on your products. Ask about their quality control processes. How do they ensure each welder meets specific standards?

Additionally, engage with their customer service. You need partners who are responsive and supportive. Slow replies can lead to frustration. Investigate their lead times as well. Long waits can hinder your production goals. Finally, think about the after-sales support offered. Equipment can break down unexpectedly; you should trust they will assist promptly.

| Factor | Description | Importance |

|---|---|---|

| Experience | Years in the ultrasonic welding industry | High |

| Customization | Ability to produce bespoke ultrasonic welders | Medium |

| Quality Assurance | Adherence to international quality standards | High |

| Technical Support | Post-purchase support and service available | Medium |

| Innovation | Use of the latest technology in production | High |

| Production Capacity | Ability to scale production to meet demand | High |

| Customer Reviews | Feedback and ratings from previous clients | Medium |

| Pricing | Cost competitiveness and value for money | High |

When considering an ultrasonic welder factory for your business, quality control plays a crucial role. A factory with robust quality control processes ensures that every ultrasonic welder meets industry standards. This consistency leads to fewer defects and better performance. A commitment to quality can differentiate your products in a competitive market.

Tips: Regularly inspect and assess ultrasonic welders during production. Ensure that the factory conducts rigorous testing. This will enhance reliability and reduce the risk of failure in your applications.

It's important to recognize that not all factories prioritize quality. Some might cut corners to reduce costs. This can lead to compromised products. Look for factories that provide transparency in their quality control processes. Request data on their testing methods and defect rates. This will help identify potential risks early on.

Tips: Engage in frequent communication with the factory. Ask for updates and quality reports. Establishing this dialogue can create accountability and ensure your standards are met. Consider a factory's history and reputation, too. A well-reviewed factory is often a safer bet for your ultrasonic welding needs.

Investing in ultrasonic welding solutions can significantly enhance your business's efficiency. These machines offer a fast and effective way to bond materials. Ultrasonic welding uses high-frequency vibrations to melt and fuse components together. This method reduces production times and minimizes waste.

Cost-effectiveness is a major consideration. Initial costs for ultrasonic welding equipment can be high. However, the long-term savings are substantial. Less material waste translates to lower raw material costs. Additionally, faster production cycles mean you can meet higher demand with fewer resources.

Some businesses may find the technology complex at first. Staff training is essential for successful integration. While the initial learning curve can be daunting, the benefits outweigh these challenges. Investing time in proper training will yield positive results. Ultimately, the decision to choose ultrasonic welding should be based on careful analysis and reflection on your specific business needs.